In the world of materials science, advanced ceramics stand out as a remarkable class of materials, offering a unique combination of properties that make them indispensable in a wide range of industries. These materials are engineered to perform under the most demanding conditions, providing solutions that are often unattainable with conventional materials like metals and polymers.

Advanced ceramics, also known as technical ceramics, are composed of inorganic, non-metallic materials that are processed at high temperatures. Unlike traditional ceramics used in pottery and construction, advanced ceramics are designed for specific, high-performance applications. Their exceptional properties include high hardness, strength, thermal stability, and resistance to wear and corrosion, among others.

Table of Contents

Understanding the properties of advanced ceramics is crucial for several reasons. Firstly, it allows engineers and designers to select the appropriate material for specific applications, ensuring optimal performance and longevity. Secondly, it helps in solving complex engineering challenges, where conventional materials may fail. Lastly, it drives innovation, leading to the development of new technologies and improved processes.

The applications of advanced ceramics span a diverse range of industries:

Industrial Use: Key in manufacturing processes and machinery components, offering superior wear and corrosion resistance.

Electronics: Employed in insulators, substrates, and semiconductors because of their excellent electrical properties.

Automotive: Applied in engine parts, braking systems, and sensors, enhancing performance and reliability.

Energy: Vital in fuel cells, nuclear reactors, and renewable energy technologies for their durability and efficiency under extreme conditions.

Semiconductor: Crucial in wafer processing, packaging, and electronic components due to their thermal and electrical stability.

Chemical: Used in reactors, pumps, and valves, providing excellent chemical inertness and resistance to aggressive environments.

Medical: Essential for dental implants, joint replacements, and surgical tools, thanks to their biocompatibility and hardness.

Aerospace: Used in turbine blades, heat shields, and engine components due to their high temperature and wear resistance.

In this article, we will delve deeper into the various properties of advanced ceramics, exploring how these materials address specific challenges and enhance performance in different applications. Advanced ceramics are the materials of choice for cutting-edge technology because of their exceptional properties, including high hardness, strength, thermal stability, chemical resistance, and unique electrical and optical characteristics. Stay with us as we uncover the fascinating world of advanced ceramics and discover why they are indispensable in modern industry and technology.

Mechanical Properties of Advanced Ceramics

High Hardness

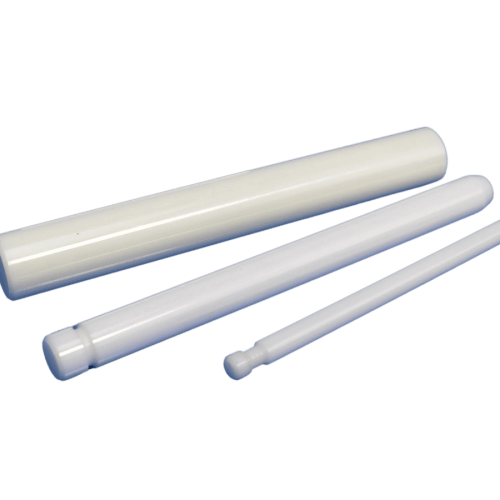

One of the most notable mechanical properties of advanced ceramics is their high hardness. Hardness refers to the ability of a material to resist deformation, particularly permanent deformation, scratching, and indentation. This property is crucial for applications where durability and longevity are essential.

When compared to other materials, advanced ceramics exhibit significantly higher hardness levels. For instance, materials like silicon carbide and alumina are much harder than most metals, including hardened steel. This exceptional hardness makes advanced ceramics ideal for cutting tools, abrasives, and protective coatings, where resistance to wear and surface damage is critical.

High Strength

Advanced ceramics also possess high strength, which is a measure of the material’s ability to withstand an applied load without failure. There are several types of strength to consider:

- Tensile Strength: The resistance to being pulled apart.

- Compressive Strength: The resistance to being compressed or squashed.

- Flexural Strength: The resistance to bending.

The high tensile and compressive strengths of advanced ceramics make them suitable for applications that require materials to endure significant mechanical stress. For example, zirconia ceramics are often used in structural components and dental implants due to their excellent strength characteristics.

Applications requiring high strength include:

- Cutting Tools: Ceramic blades and inserts remain sharp and effective for longer periods compared to metal counterparts.

- Armor Systems: Ceramic armor provides superior protection against ballistic threats due to its high compressive strength.

- Engine Components: Ceramic parts in engines can withstand high loads and temperatures, enhancing performance and longevity.

Wear Resistance

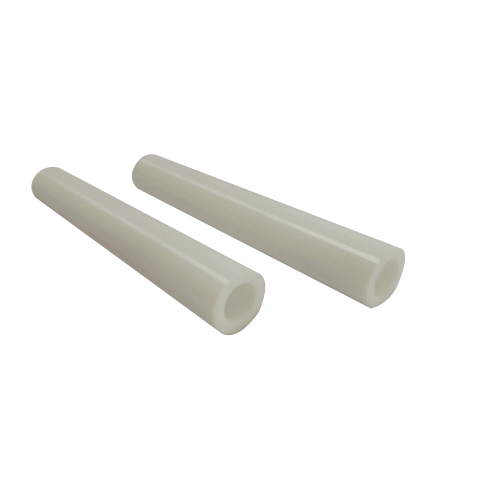

Wear resistance is another critical property of advanced ceramics, referring to their ability to withstand gradual degradation due to mechanical action such as friction, abrasion, and erosion. This property is particularly important in applications where components are exposed to harsh conditions and continuous wear.

Advanced ceramics like silicon carbide and alumina are highly resistant to wear, making them ideal for use in environments where durability is paramount. They maintain their structural integrity and performance even after prolonged exposure to abrasive materials and erosive forces.

Examples of wear-resistant applications include:

- Industrial Machinery: Ceramic components in pumps, valves, and seals offer extended service life by resisting wear and tear.

- Mining and Drilling: Ceramics are used in wear-resistant linings and drilling tools, significantly reducing downtime and maintenance costs.

- Aerospace: Ceramic coatings on turbine blades and other high-wear parts ensure reliability and efficiency under extreme conditions.

Thermal Properties of Advanced Ceramics

Understanding the thermal properties of advanced ceramics is essential, as these materials often operate in environments where high temperatures and rapid temperature changes are the norm. The unique thermal characteristics of advanced ceramics make them suitable for a wide range of high-performance applications.

High-Temperature Stability

One of the key thermal properties of advanced ceramics is their high-temperature stability. This refers to the ability of ceramics to maintain their structural integrity and performance even at elevated temperatures. Unlike many metals and polymers that may soften, melt, or degrade at high temperatures, advanced ceramics such as alumina, silicon carbide, and zirconia can withstand extreme heat without losing their strength or functionality.

Applications where high temperature stability is crucial include:

- Furnaces: Ceramic linings and components in industrial furnaces provide excellent heat resistance, ensuring efficient and reliable operation.

- Engines: In automotive and aerospace engines, ceramic parts such as spark plugs and turbocharger rotors maintain performance under high thermal stress.

- Turbines: Gas turbines and steam turbines use ceramic blades and components to operate efficiently at high temperatures, improving overall efficiency and lifespan.

Low Thermal Expansion

Low thermal expansion is another important property of advanced ceramics. The coefficient of thermal expansion (CTE) measures how much a material expands when heated. Ceramics generally have a low CTE, meaning they undergo minimal dimensional changes with temperature fluctuations. This property is vital in applications where maintaining precise dimensions is critical, as even slight expansions or contractions can affect performance.

Applications where low thermal expansion is essential include:

- Precision Instruments: Components in scientific instruments and measuring devices require high dimensional stability to ensure accurate results.

- Electronics: Ceramic substrates and packages in electronic devices must remain stable to avoid circuit damage and maintain performance.

- Optical Systems: Lenses and mirrors in telescopes and other optical equipment use ceramics to prevent distortion caused by temperature changes.

Thermal Conductivity

Thermal conductivity in ceramics can vary widely, from very high to very low, depending on the material. This range allows advanced ceramics to be tailored for specific thermal management applications. For instance, materials like beryllium oxide have high thermal conductivity, making them suitable for heat sinks that dissipate heat effectively. On the other hand, materials like zirconia have low thermal conductivity, serving as excellent thermal insulators.

Examples of applications based on thermal conductivity include:

- Heat Sinks: High thermal conductivity ceramics are used in electronics to manage and dissipate heat, ensuring components operate within safe temperature ranges.

- Thermal Insulators: Low thermal conductivity ceramics are used in protective barriers and insulation to prevent heat transfer and protect sensitive components or environments.

Thermal Shock Resistance

Thermal shock resistance is the ability of a material to withstand rapid temperature changes without cracking or breaking. Advanced ceramics excel in this property, making them suitable for applications where materials are subjected to sudden and extreme temperature fluctuations.

Applications where thermal shock resistance is vital include:

- High-Temperature Processing: In industries such as glass manufacturing and metal casting, ceramic components must endure rapid heating and cooling cycles without failure.

- Thermal Cycling Environments: Components in space exploration and high-altitude aviation experience extreme temperature variations and rely on ceramics for their resilience.

- Laboratory Equipment: Crucibles and other labware made from advanced ceramics can withstand rapid temperature changes during experiments and processes.

Electrical Properties of Advanced Ceramics

In addition to their impressive mechanical and thermal properties, advanced ceramics also possess unique electrical characteristics that make them indispensable in modern technology. Their ability to function as electrical insulators, semiconductors, and piezoelectric materials allows them to be utilized in a wide range of electronic and electrical applications.

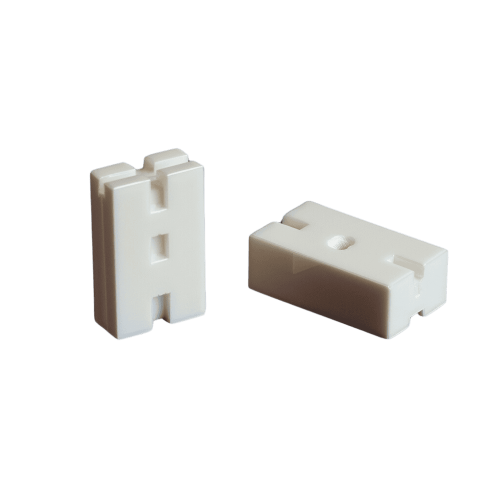

Electrical Insulation

One of the most significant electrical properties of advanced ceramics is their excellent electrical insulation. These materials exhibit high dielectric strength and resistivity, which means they can effectively prevent the flow of electrical current, making them ideal for use in environments where electrical insulation is critical.

Applications of advanced ceramics in electrical insulation include:

- Electronics: Ceramic insulators are used in a variety of electronic components, including resistors, capacitors, and integrated circuit packages, to protect sensitive parts and ensure reliable performance.

- Insulators: Power transmission and distribution systems use ceramic insulators to support and isolate electrical conductors, preventing electrical faults and ensuring safety.

- Substrates: In printed circuit boards and microelectronics, ceramic substrates provide a stable and insulating platform for mounting electronic components.

Semiconducting Properties

Certain advanced ceramics, such as silicon carbide, exhibit semiconducting properties. These materials can conduct electricity under certain conditions, making them essential for applications that require controlled electrical conductivity.

Applications of semiconducting ceramics include:

- Power Electronics: Silicon carbide semiconductors are used in high-power and high-frequency applications, such as power converters, inverters, and uninterruptible power supplies, due to their high efficiency and thermal stability.

- Sensors: Semiconducting ceramics are used in gas sensors, pressure sensors, and temperature sensors, where they can detect changes in environmental conditions and convert them into electrical signals.

Piezoelectric Properties

Piezoelectricity is a property of certain ceramics that allows them to generate an electric charge in response to mechanical stress. This unique characteristic is utilized in a variety of applications where the conversion between mechanical and electrical energy is required.

Applications of piezoelectric ceramics include:

- Sensors: Piezoelectric ceramics are used in accelerometers, pressure sensors, and ultrasonic transducers to convert mechanical changes into electrical signals for measurement and monitoring.

- Actuators: In precision control systems, piezoelectric actuators are used to convert electrical signals into precise mechanical movements, essential for applications like autofocus mechanisms in cameras and fuel injection systems in engines.

- Transducers: Medical ultrasound equipment, sonar devices, and musical instruments use piezoelectric transducers to convert electrical energy into sound waves and vice versa.

Dielectric Properties

Advanced ceramics also exhibit excellent dielectric properties, characterized by a high dielectric constant and low loss. These properties are crucial for the efficient storage and transfer of electrical energy in various electronic devices.

Applications of ceramics with superior dielectric properties include:

- Capacitors: Ceramic capacitors are widely used in electronic circuits for energy storage, filtering, and signal processing due to their high dielectric constant and stability.

- Resonators: In communication devices, ceramic resonators provide frequency stabilization and signal filtering, ensuring clear and accurate signal transmission.

- Microwave Devices: Advanced ceramics are used in microwave resonators, filters, and antennas, where their dielectric properties enable efficient operation at high frequencies.

Chemical Properties of Advanced Ceramics

Advanced ceramics are not only renowned for their mechanical and thermal properties but also for their outstanding chemical resistance. These materials can withstand aggressive chemical environments and maintain their integrity over time, making them indispensable in various industries where chemical stability is crucial.

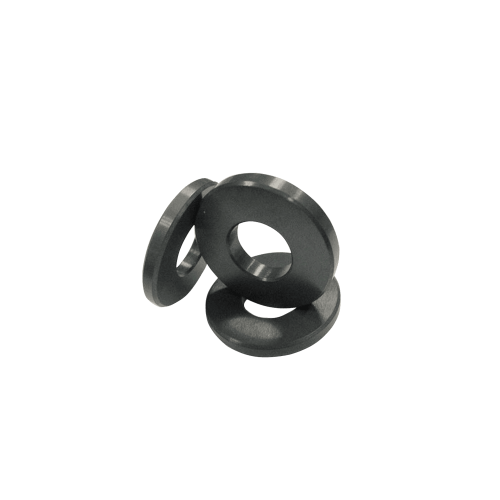

Corrosion Resistance

One of the most significant chemical properties of advanced ceramics is their resistance to corrosion. These materials are highly resistant to attack by acids, alkalis, and other corrosive substances, which allows them to perform reliably in harsh chemical environments where metals and polymers would fail.

Applications of corrosion-resistant ceramics include:

- Chemical Processing: Ceramic components are used in reactors, pipes, and valves to handle aggressive chemicals without degrading, ensuring long-term reliability and safety in chemical plants.

- Harsh Environments: In industries such as oil and gas, ceramics are employed in equipment exposed to corrosive fluids and gases, preventing corrosion-related failures and reducing maintenance costs.

- Marine Applications: Advanced ceramics are used in marine environments where saltwater corrosion is a significant concern, providing durable solutions for underwater structures and equipment.

Oxidation Resistance

Oxidation resistance is another critical property of advanced ceramics, particularly important in high-temperature and oxidative environments. Unlike metals, which can oxidize and degrade when exposed to high temperatures and oxygen, ceramics maintain their structural integrity and performance.

Applications of oxidation-resistant ceramics include:

- Aerospace: Ceramic components in jet engines, turbine blades, and heat shields can withstand high temperatures and oxidative conditions, ensuring reliable performance and longevity in aerospace applications.

- Energy Industries: In power generation, ceramics are used in gas turbines, nuclear reactors, and fuel cells, where they resist oxidation and maintain efficiency under extreme conditions.

- Automotive: High-temperature ceramics in exhaust systems and catalytic converters offer excellent oxidation resistance, contributing to better performance and emissions control.

Inertness

Advanced ceramics are known for their inertness, both bio-inert and chemically inert, making them suitable for applications where interactions with the surrounding environment must be minimized. Bio-inert ceramics do not react with biological tissues, while chemically inert ceramics do not react with other substances they come into contact with.

Applications of inert ceramics include:

- Medical Implants: Bio-inert ceramics like alumina and zirconia are used in joint replacements, dental implants, and bone screws, providing long-lasting and biocompatible solutions that do not elicit adverse reactions in the body.

- Pharmaceutical Machinery: Chemically inert ceramics are used in the manufacturing of pharmaceuticals, where they come into contact with sensitive chemicals and drugs, ensuring purity and preventing contamination.

- Food Processing: In the food industry, ceramic components in processing equipment and packaging lines prevent chemical reactions that could compromise food safety and quality.

Optical Properties of Advanced Ceramics

The optical properties of advanced ceramics are as impressive as their mechanical, thermal, and chemical characteristics. These properties make them highly valuable in various high-tech applications where clarity, light manipulation, and optical performance are crucial.

Transparency and Translucency

One of the standout optical properties of certain advanced ceramics is their ability to be transparent or translucent. Materials like sapphire and aluminum oxynitride (ALON) are examples of ceramics that can be made optically clear. These materials offer a unique combination of durability and transparency, making them ideal for demanding applications.

Applications of transparent ceramics include:

- Optics: Sapphire lenses and windows are used in high-performance optical systems, providing excellent clarity and scratch resistance. They are commonly found in cameras, watches, and scientific instruments.

- Protective Windows: ALON is used in bulletproof windows and other protective applications due to its transparency and superior hardness, offering both visibility and protection.

- Photonics: Transparent ceramics are employed in photonic devices, such as laser windows and optical isolators, where they must transmit light without distortion while enduring harsh conditions.

Photoluminescence

Photoluminescence is a property of some ceramics that allows them to emit light when excited by a source of energy, such as ultraviolet light or an electrical current. Yttrium aluminum garnet (YAG) is a well-known example of a photoluminescent ceramic, widely used in various lighting and display technologies.

Applications of photoluminescent ceramics include:

- Lighting: YAG phosphors are used in white LED lighting, providing high brightness and efficiency by converting blue or ultraviolet light into white light.

- Displays: Photoluminescent ceramics are integral to display technologies, such as those used in televisions and smartphones, enhancing color accuracy and brightness.

- Lasers: YAG crystals doped with rare earth elements are used in solid-state lasers, offering high efficiency and stable performance for applications in medicine, industry, and research.

Refractive Index

The refractive index is a measure of how much a material can bend light. Advanced ceramics with specific refractive indices are essential for precise optical applications. Materials with a high refractive index can focus light more effectively, which is crucial for various optical devices.

Applications of ceramics with tailored refractive indices include:

- Lenses: High-refractive-index ceramics are used in lenses for cameras, microscopes, and telescopes, providing excellent image quality and clarity.

- Optical Fibers: Ceramics with specific refractive indices are used in the core and cladding of optical fibers, enabling efficient light transmission over long distances with minimal signal loss.

- Photonic Devices: Devices such as waveguides and modulators rely on ceramics with precise refractive properties to manipulate light for telecommunications and data transfer.

Environmental Properties of Advanced Ceramics

In addition to their remarkable mechanical, thermal, chemical, and optical properties, advanced ceramics also exhibit important environmental characteristics. These properties make them not only effective in high-performance applications but also beneficial for sustainable and biocompatible solutions.

Biocompatibility

Biocompatibility is a critical property for materials used in medical applications. Biocompatible ceramics do not provoke an immune response when implanted in the body, making them ideal for medical devices and implants.

The importance of biocompatibility in medical applications includes:

- Safety: Biocompatible ceramics do not cause adverse reactions, infections, or toxicity, ensuring patient safety and comfort.

- Longevity: These materials are durable and can last for many years within the body without degrading or losing functionality.

Examples of biocompatible ceramics include:

- Alumina: Widely used in hip replacements, dental implants, and bone screws due to its hardness, wear resistance, and biocompatibility.

- Zirconia: Known for its high strength and toughness, zirconia is used in dental crowns, bridges, and joint replacements, offering excellent performance and biocompatibility.

Sustainability

Sustainability is becoming increasingly important in the manufacturing and materials industries. Advanced ceramics contribute to sustainability through their environmental impact and recyclability.

Environmental impact and recyclability include:

Durability: The long lifespan of ceramic components reduces the need for frequent replacements, minimizing waste and resource consumption.

Recyclability: Many ceramics can be recycled at the end of their life cycle, contributing to a circular economy and reducing landfill waste.

Advances in eco-friendly ceramic processing include:

Energy Efficiency: Innovations in ceramic processing, such as low-temperature sintering and energy-efficient manufacturing techniques, reduce the environmental footprint of ceramic production.

Green Materials: The development of ceramics from natural and renewable sources, as well as the reduction of harmful additives, enhances the sustainability of ceramic materials.

Advanced ceramics offer a unique combination of biocompatibility and sustainability, making them ideal for a wide range of applications. Their ability to meet the stringent requirements of medical devices while also contributing to environmental goals highlights their versatility and importance in modern technology.

Conclusion

Advanced ceramics are with diverse properties, from their mechanical strength and thermal stability to their chemical resistance and optical clarity. These remarkable materials play a crucial role in various industries, including aerospace, medical, electronics, energy, automotive, semiconductor, chemical, and industrial applications.

By understanding the unique properties of advanced ceramics, engineers and designers can select the best materials for their specific needs, ensuring optimal performance and longevity. Whether you are looking for materials that can withstand extreme temperatures, resist corrosion, or provide precise optical performance, advanced ceramics offer reliable solutions.

If you have any questions or need assistance in choosing the right ceramic material for your application, please contact us. Our team of experts is ready to help you find the perfect solution to meet your needs.