Table of Contents

Did you know that the global ceramic heat sink market is projected to reach USD 11.78 billion by 2030, growing at a CAGR of 7.5% from 2023? This remarkable growth underscores the critical role ceramic heat sinks play in managing heat across industries like electronics, automotive, and aerospace. Unlike traditional metal heat sinks, ceramics offer exceptional electrical insulation and corrosion resistance, making them vital for high-performance applications.

At Eshino Precision, we’re leaders in designing and manufacturing high-quality ceramic heat sinks tailored to keep your devices efficient and reliable. This guide is your one-stop resource—whether you’re an engineer, designer, or industry professional—covering everything from material properties to design, manufacturing, and beyond.

Introduction to Ceramic Heat Sinks

What Are Ceramic Heat Sinks?

Ceramic heat sinks are advanced thermal management solutions designed to dissipate heat from sensitive electronic components. Made from specialized ceramic materials, they excel at pulling heat away, much like a cooling breeze on a hot day. From smartphones to spacecraft, these heat sinks ensure devices operate within safe temperature ranges, preventing slowdowns or failures.

The Role in Modern Technology

In today’s high-tech world, heat is a persistent challenge. Industries like electronics, automotive, and aerospace rely on ceramic heat sinks to manage thermal loads. Unlike metal alternatives, ceramics don’t conduct electricity, offering superior insulation that’s critical in environments where safety and reliability are non-negotiable.

Eshino Precision’s Expertise

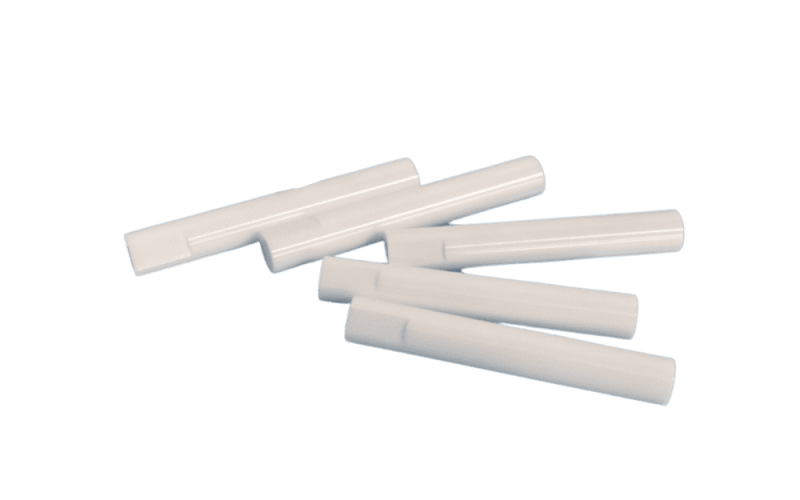

At Eshino Precision, we leverage cutting-edge technology to craft ceramic heat sinks that meet your unique needs. Whether you’re enhancing a gadget or building industrial equipment, our solutions—featuring products like alumina ceramic rods and silicon nitride ceramic rods—ensure optimal performance. Explore our product catalog for custom options.

Why Are Ceramic Heat Sinks So Important?

Excess heat can cripple electronics, causing malfunctions or permanent damage. Ceramic heat sinks combat this by efficiently dissipating heat, a necessity in high-stakes applications like electric vehicles or satellites. Their lightweight design and resistance to harsh conditions make them indispensable. Learn more about their impact in our blog, How Technical Ceramics Are Transforming the Electronics Industry.

Key Material Properties of Ceramic Heat Sinks

Understanding Ceramic Materials

Not all ceramics are created equal. The top materials for heat sinks—Alumina (Al2O3), Silicon Nitride (Si3N4), and Silicon Carbide (SiC)—each bring unique strengths. These properties determine their effectiveness in thermal management.

Material Breakdown

- Aluminum Nitride (AlN): With a thermal conductivity of 180 W/m·K, AlN rapidly transfers heat while providing excellent electrical insulation—perfect for electronics.

- Silicon Carbide (SiC): Boasting 120 W/m·K and exceptional durability, SiC shines in rugged applications like automotive systems.

- Alumina (Al2O3): At 25-35 W/m·K, it’s cost-effective, corrosion-resistant, and ideal for budget-conscious projects.

Comparison Table

| Material | Thermal Conductivity (W/m·K) | Electrical Insulation | Corrosion Resistance |

|---|---|---|---|

| Aluminum Nitride (AlN) | 180 | Excellent | High |

| Silicon Carbide (SiC) | 120 | Good | High |

| Alumina (Al2O3) | 25-35 | Excellent | High |

Why AlN and SiC Are the Go-To Choices

AlN and SiC dominate due to their balance of heat transfer and resilience. Dr. Jane Smith, an industry expert, notes, “The unique combination of high thermal conductivity and electrical insulation in ceramics like AlN makes them indispensable in modern electronics, where managing heat without compromising safety is paramount.” Discover more in our Silicon Nitride Ceramics blog.

Designing Ceramic Heat Sinks

Key Design Considerations

Designing a ceramic heat sink requires precision. Factors like material choice—think Alumina or SiC—shape, and size must align with your application. Fins or pins increase surface area for better heat dissipation, a concept we explore in our structures page.

Balancing Performance and Practicality

Thicker designs handle more heat but add weight and cost. Cooling methods—natural or forced—also play a role. Forced cooling with fans boosts performance but requires additional setup. Our ceramic substrates offer versatile options for tailored solutions.

Managing Thermal Stress

Ceramics resist thermal expansion but can crack under sudden temperature shifts. Thoughtful design mitigates this risk, ensuring longevity. Check out our high-temperature resistance page for insights.

Custom Designs for Every Need

At Eshino Precision, we’ve boosted LED efficiency by 30% with custom AlN heat sinks. Our ceramic plates and discs showcase our design flexibility.

Manufacturing Ceramic Heat Sinks

Production Techniques

Manufacturing ceramic heat sinks blends art and science. Methods like pressing and sintering create robust ceramic rods, while injection molding suits complex shapes. Discover more in What Are Structural Ceramics?.

Advanced Methods

3D printing enables intricate designs, and machining ensures precision despite ceramics’ brittleness. Our ceramic nozzles exemplify this capability.

Quality Assurance

We use top-tier materials and processes at Eshino Precision. Our ceramic valves reflect our commitment to excellence.

Quality You Can Trust

Every heat sink meets rigorous standards, ensuring reliability for applications from oil and gas to new energy.

Applications of Ceramic Heat Sinks

Where Are Ceramic Heat Sinks Used?

Ceramic heat sinks play a vital role across various industries, ensuring devices remain cool and operational. Here’s where they shine:

- Electronics and Power Electronics: Used in high-power LEDs, power transistors, and IGBTs, ceramic heat sinks dissipate heat while providing electrical insulation to prevent short circuits and extend device life.

- Automotive: Electric vehicles (EVs) and hybrids depend on them to cool battery packs and power electronics, meeting the rising demand for efficient thermal management in the EV sector.

- Aerospace and Defense: Satellites, aircraft, and military gear benefit from their lightweight design and ability to withstand high temperatures.

- Industrial Equipment: In furnaces and kilns, their corrosion resistance and durability make them ideal for high-temperature processes.

Real-World Impact: A Case Study

For a leading LED manufacturer, custom Aluminum Nitride (AlN) heat sinks improved efficiency by 30% and significantly extended product lifespan. This showcases how tailored ceramic solutions can enhance performance in real-world applications.

Ceramic Heat Sinks vs. Metal Heat Sinks

Why Choose Ceramic Over Metal?

While metal heat sinks like aluminum and copper are popular, ceramics offer unique advantages. Here’s a comparison:

| Property | Ceramic Heat Sinks | Metal Heat Sinks (Al/Cu) |

|---|---|---|

| Thermal Conductivity | High (e.g., AlN: 180 W/m·K) | Very High (Al: 230, Cu: 400 W/m·K) |

| Electrical Insulation | Excellent | Poor (conductive) |

| Corrosion Resistance | Excellent | Good (can corrode) |

| Weight | Lighter | Heavier |

| Cost | Higher | Lower |

| Design Flexibility | Good, but brittle | Excellent, ductile |

When to Choose Ceramic Heat Sinks

Choose ceramics when you need:

- Electrical insulation (e.g., in electronics).

- Corrosion resistance (e.g., in chemical environments).

- Lightweight solutions (e.g., in aerospace).

They’re less ideal where cost is a primary concern or extreme thermal conductivity is required.

Maintenance and Longevity

Why Ceramic Heat Sinks Last Longer

Ceramic heat sinks excel in durability. They resist corrosion (unlike metals) and maintain performance at high temperatures without deforming, making them perfect for harsh conditions.

Minimal Maintenance Required

These heat sinks need little upkeep, saving time and costs. However, avoid sudden temperature shifts or mechanical stress to prevent cracking.

Longevity in Action

In industries like oil and gas, ceramic heat sinks endure extreme environments for years, proving their reliability in critical applications.

Future Trends in Ceramic Heat Sinks

What’s Next for Ceramic Heat Sinks?

Innovations are shaping the future of ceramic heat sinks:

- Advanced Materials: New ceramics, like graphene-enhanced options, aim to boost thermal conductivity.

- 3D Printing: Enables custom, complex designs for better heat dissipation.

- Hybrid Designs: Combining ceramics with metals or composites for enhanced performance.

- Smart Heat Sinks: Sensors for real-time heat management, aligning with IoT trends.

- Sustainability: Eco-friendly materials and processes to meet green demands.

Market Growth and Opportunities

The ceramic heat sink market is projected to hit USD 11.78 billion by 2030, with a 7.5% CAGR, driven by growth in electronics, automotive, and renewable energy sectors.

Frequently Asked Questions

What advantages do ceramic heat sinks offer over metal?

They provide better electrical insulation, corrosion resistance, lighter weight, and lower maintenance needs, ideal for demanding environments.

What materials are used in ceramic heat sinks?

Common options include Aluminum Nitride (AlN), Silicon Carbide (SiC), Alumina (Al2O3), and Beryllium Oxide (BeO), each suited to specific uses.

How are ceramic heat sinks made?

They’re crafted via pressing and sintering, injection molding, 3D printing, or machining, ensuring precision and quality.

Where are ceramic heat sinks applied?

They’re found in electronics, automotive, aerospace, and industrial equipment.

What’s new in ceramic heat sink technology?

Expect advances in materials, 3D printing, hybrid designs, smart features, and sustainability.

Conclusion

Ceramic heat sinks are essential for efficient thermal management, offering unique properties that make them indispensable in electronics, automotive, aerospace, and industrial applications. Their ability to combine high thermal conductivity with electrical insulation and durability sets them apart. As technology evolves, innovations like 3D printing and smart designs promise even greater potential.

Whether you’re upgrading devices or tackling extreme conditions, ceramic heat sinks deliver reliable solutions. Explore how they can enhance your projects and keep your systems running smoothly.

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.