Custom Ceramic Parts Manufacturer in China

ISO 9001 & Apple Trusted Factory

- Low MOQ, start form 1 piece

- Tolerance as tight as ±0.001mm

- Technical support for 24/7/365

- Full material suite: Zirconia / Alumina / Si3N4 / SiC / AlN

- From prototypes to 2 M+ pcs / year volume

Do These Challenges Sound Familiar?

Your projects demand materials that outperform metals and plastics. But finding a manufacturing partner who can meet your exact specifications for complex ceramic parts is a challenge.

Struggling to achieve tight tolerances and complex geometries?

Facing component failure in extreme temperature or corrosive environments?

Experiencing long lead times and poor communication from your current supplier?

We provide the solution.

Your End-to-End Advanced Ceramics Manufacturing Partner

We specialize in turning your designs into reality. Our comprehensive capabilities ensure quality and precision at every stage.

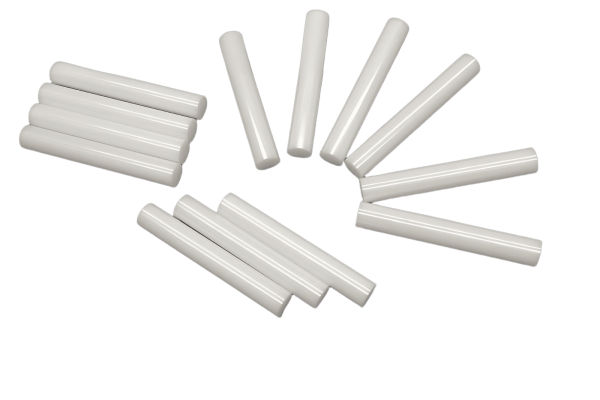

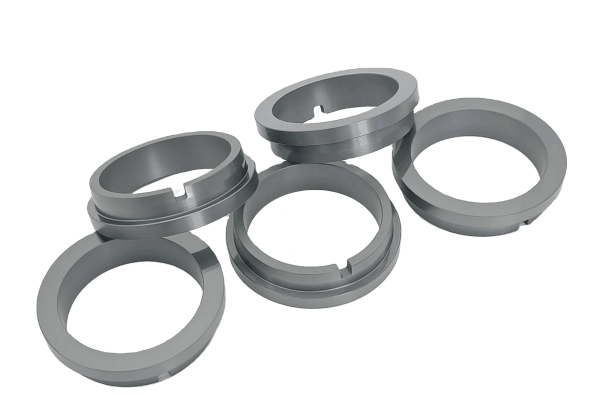

Precision CNC Machining

Consistent, high-volume manufacturing to meet your production schedule.

Precision Grinding & Lapping

Achieving superior surface finishes and ultra-tight tolerances.

Prototyping & NPI

Rapid development to validate your design before scaling.

Full-Scale Production

Consistent, high-volume manufacturing to meet your production schedule.

Material Expertise

In-house engineering support to help you select the perfect material.

Quality Assurance

Rigorous inspection with advanced metrology equipment at every step.

Your End-to-End Advanced Ceramics Manufacturing Partner

Unmatched Toughness for Extreme Durability

From Feature to Your Benefit:

- Exceptional fracture toughness -> Prevents catastrophic failure in high-impact and high-load applications.

- Superior wear & corrosion resistance -> Extends your equipment’s service life, dramatically reducing downtime and replacement costs.

- Steel-like thermal expansion -> Ensures reliable performance when assembling ceramic components with metal parts.

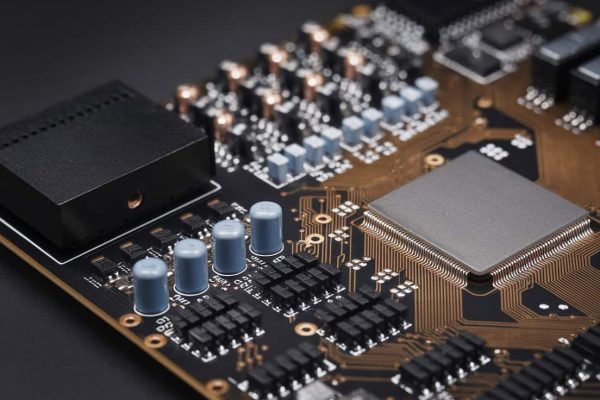

The Gold Standard for Insulation and Wear Resistance

From Feature to Your Benefit:

- Excellent electrical insulation -> Guarantees safety and reliability in your high-voltage electronic systems.

- Extreme hardness & wear resistance -> Maintains critical dimensions under abrasive conditions, ensuring consistent performance.

- High thermal stability -> Withstands high-temperature processes without degradation, protecting your operational integrity.

Supreme Reliability in Extreme Thermal and Mechanical Stress

From Feature to Your Benefit:

- Outstanding thermal shock resistance -> Survives rapid and extreme temperature changes where other ceramics crack and fail.

- High strength at high temperatures -> Provides unparalleled reliability for demanding applications like bearings, welding pins, and turbine components.

- Low density -> Reduces weight and inertia in moving systems, boosting efficiency and speed.

Ultimate Performance in Abrasive and Corrosive Environments

From Feature to Your Benefit:

- Near-diamond hardness -> Delivers the ultimate wear resistance, even against the most abrasive slurries and materials.

- Excellent thermal conductivity -> Rapidly dissipates heat away from critical areas, preventing thermal damage.

- Superior chemical inertness -> Resists the most aggressive chemicals, ensuring process purity and component longevity.

Case Studies

Silicon Nitride (Si₃N₄) Solves MWD Tool Failure

Challenge: A leading oilfield services client faced costly MWD tool failures in harsh drilling environments due to failing metal bushings.

Solution: We engineered custom, precision-ground Silicon Nitride bushings. The new components delivered a 4X longer operational lifespan, an 85% reduction in costly failures, and dramatically improved reliability in extreme heat and vibration, saving the client millions in downtime.

Silicon Carbide (SiC) Enables Next-Gen Metrology

Challenge: A CMM manufacturer needed a structural beam with stiffness and thermal stability that steel or granite could not provide.

Solution: We delivered a large, lightweighted beam machined from Sintered Silicon Carbide. Its superior properties enabled their machine to achieve 50% faster measurement speeds and a 3X improvement in repeatable accuracy, setting a new industry performance benchmark.

Why Leading Engineers Choose Us

Trusted by WORLD CLASS Companies

Uncompromising Precision: We don’t just meet specifications; we build our reputation on them. Our quality-first process guarantees your parts work as designed.

True Engineering Partnership: Our team works with you from concept to completion. We provide Design for Manufacturability (DFM) feedback to optimize your parts for performance and cost.

Proven Reliability: With over two decades of experience, we have a track record of delivering critical components on time for the world’s most innovative companies.

Our Clients Love us

The team at Eshino has been a critical partner for us. Their attention to detail and ability to hold tight tolerances on complex zirconia components is second to none. A truly reliable supplier.

David D.

Lead Engineer,

In semiconductor manufacturing, component purity and thermal stability are everything. Eshino delivered alumina and silicon carbide parts that exceeded our cleanliness specifications and performed flawlessly in high-temperature process chambers. Their quality control is world-class, making them an essential part of our supply chain.

Dr. Evelyn R.

Senior Process Engineer

We replaced a series of steel guide rails with zirconia parts from Eshino on our high-speed packaging line. The result was a dramatic reduction in wear and a 50% increase in the maintenance interval. The precision of the parts was perfect, and they dropped right into place. A fantastic ROI for us.

Mark Chen

Head of Automation

Our Products

Applications

Mechanical Engineering

Semiconductor

Energy

Automotives

Oil & Gas

Electronics

Get Your Custom Ceramic Parts Started Today

Need an technical ceramic expert for your application? You are more than welcome to leave your contact information and we will be in touch within 12 hours. Your intellectual property is 100% secure with us.

Our Simple, Transparent Partnership Process

At Eshino Precision, We turn complex Into Simple! Follow the following 4 steps to start today!

Tell us what you need

Tell us as specifc as possible of your needs, provide the drawing, applications and share your idea.

Get Solution & Quote

We will work on the best solution according to your requirements and drawing, the specifc quote will be provided within two working days.

Rapid Prototyping

We produce and ship your samples for testing and validation as quick as one week.

Approve for Mass Production

We will start mass production after getting approval and deposit, and each part will be checked before shipping out.