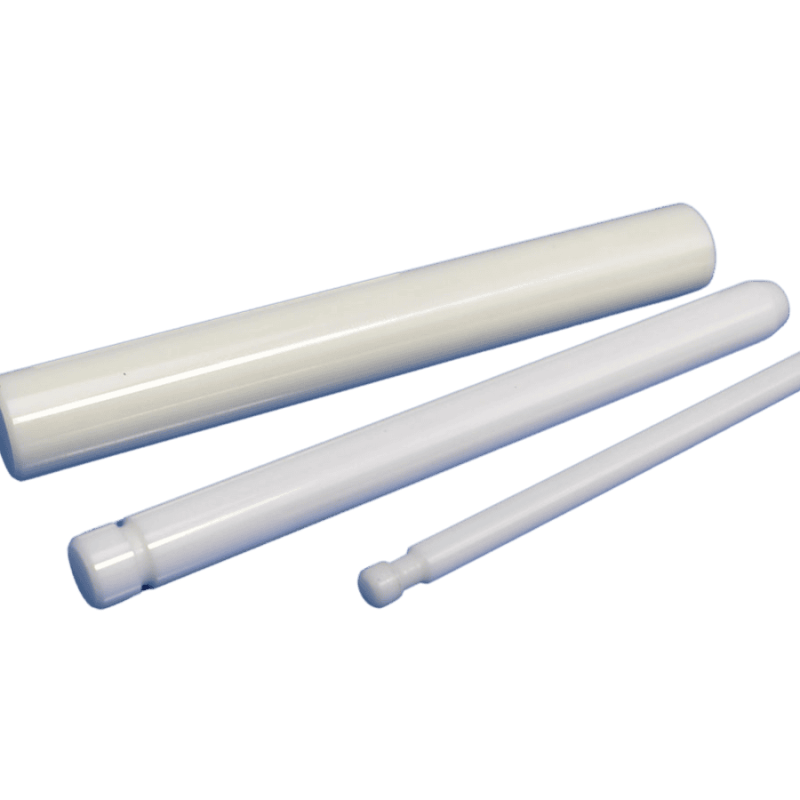

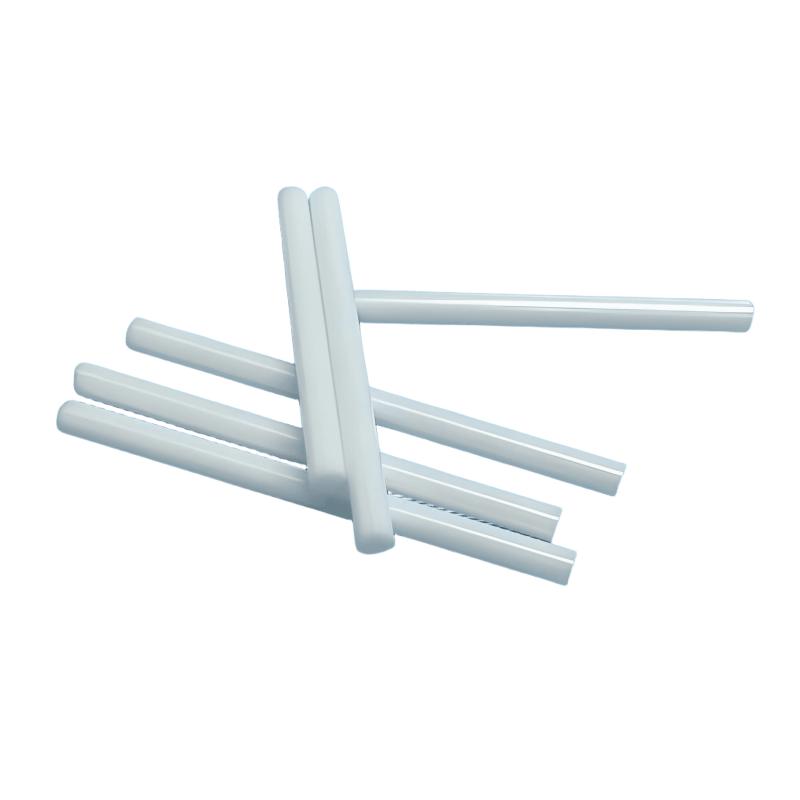

The primary attributes of ceramic rods include high strength, exceptional fracture toughness, elevated hardness and density, stability, wear resistance, corrosion resistance, and the ability to withstand high temperatures.

Ceramic rods, made from high-performance ceramic materials, are integral in systems requiring materials with exceptional strength, thermal resistance, and electrical insulation properties. These rods are widely used due to their ability to perform under extreme conditions.

Features:

High-Temperature Resistance: They can withstand extremely high temperatures, making them ideal for use in environments where other materials would degrade.

Electrical Insulation: Ceramic rods are excellent electrical insulators, which is crucial in electrical and electronic applications.

Corrosion Resistance: These rods resist corrosion from chemicals, making them suitable for use in chemically aggressive environments.

Mechanical Strength: Despite their brittleness, ceramic rods typically exhibit high mechanical strength, especially in compression.

Wear Resistance: The hardness of ceramics contributes to their resistance to wear and abrasion.

Low Thermal Expansion: Ceramic materials generally have low thermal expansion coefficients, providing stability in applications involving temperature fluctuations.

Chemical Inertness: They are chemically stable and do not react with most acids, alkalis, and solvents.

Biocompatibility: Some types of ceramic rods are biocompatible, which is important in medical applications.

Industrial ceramic rods not only function in normal conditions but also excel in harsh environments characterized by high temperatures, high pressure, insulation requirements, and corrosive conditions. Using industrial ceramic rods ensures that instruments operate normally without suffering from fractures, wear, corrosion, or damage.

For any customized requests, talk with us now! We’re here 24/7/365, ensuring you get the best, always.

A client needed ceramic rods at 550mm with a 0.1 straightness, a task many deemed impossible. Using advanced techniques and teamwork, we not only met the specs but set a new industry standard. Now, 700mm rods are routine for us, proving our unmatched expertise in advanced ceramics.

Contact us now to customize your long ceramic center rods.

We will get back to you within 12 hours.

We will be in touch within 12 hours. Your intellectual property is 100% secure with us.