Table of Contents

Did you know that Silicon Nitride (Si3N4) and Silicon Carbide (SiC) are two super-strong materials that can handle crazy heat and tough jobs? These advanced ceramics are like the superheroes of the engineering world! They’re used in things like airplanes, cars, and even electronics. But here’s the big question: which one is right for your project? In this guide, we’ll break it down so it’s super easy to understand—even for a 12-year-old! We’ll compare Silicon Nitride vs. Silicon Carbide step-by-step to help you pick the best one. Let’s dive in!

Why These Materials Matter

Silicon Nitride and Silicon Carbide are special because they’re not like regular metals or plastics. They’re ceramics, which means they’re made from stuff like sand and heated up until they’re super tough. For example, Silicon Nitride is great at staying strong when things get bumpy, while Silicon Carbide is awesome at handling heat and scratches. Engineers love them for building parts that last a long time, like ceramic bearings or ceramic seals. At Eshino Precision, we use these materials to make machines work better!

What You’ll Learn Here

By the end of this article, you’ll know the differences between Silicon Nitride and Silicon Carbide. We’ll talk about how strong they are, how they handle heat, where they’re used, and even how much they cost in 2025. Plus, we’ll share cool facts, like how Silicon Carbide is growing fast because of electric cars! Whether you’re making a rocket or a pump, this guide will help you choose. Let’s start with a quick look at both!

Quick Comparison: Silicon Nitride vs. Silicon Carbide

Before we get into the details, here’s a fast look at Silicon Nitride vs. Silicon Carbide. This is the stuff people search for most, so we’re putting it right up front!

- Silicon Nitride (Si3N4): This one’s super tough and doesn’t crack easily. It’s also great when temperatures change fast, like in a jet engine.

- Silicon Carbide (SiC): This one’s really hard—like, almost as hard as a diamond! It’s also awesome at moving heat away, perfect for electronics.

So, if you need something that won’t break when it gets hit, pick Silicon Nitride. But if you want something super hard that keeps things cool, go with Silicon Carbide. Want more? Check out our detailed pages on Silicon Nitride ceramics and Silicon Carbide ceramics!

Why This Matters to You

Knowing these basics helps you decide fast. For example, if you’re building Silicon Nitride rods for a machine that shakes a lot, that’s a smart choice. Or, if you need Silicon Carbide tubes for a hot engine, you’re on the right track. Let’s look at some numbers next!

Key Properties at a Glance

Here’s a simple table to show you how Silicon Nitride and Silicon Carbide stack up. These are the key things engineers care about!

| Property | Silicon Nitride (Si3N4) | Silicon Carbide (SiC) |

|---|---|---|

| Hardness | Lower (up to 2950 MPa) | Higher (up to 3900 MPa) |

| Toughness | Higher (up to 6.2 MPa-m^1/2) | Lower (up to 4.6 MPa-m^1/2) |

| Heat Conductivity | Lower (12-31 W/m-K) | Higher (120-170 W/m-K) |

| Density | 2.2-3.4 g/cm³ | 3.0-3.2 g/cm³ |

What These Numbers Mean

Hardness is how tough something is to scratch. Silicon Carbide wins here—it’s almost as hard as a diamond! Toughness is about not cracking when hit, and Silicon Nitride is the champ. Heat conductivity shows how well heat moves through it—Silicon Carbide is way better at this. Density is how heavy it is, and they’re pretty close. These numbers help you pick the right material for your job, like ceramic cutting tools or ceramic valves.

Expert Insight

“Silicon Nitride’s toughness makes it a go-to for parts that take a beating, while Silicon Carbide’s hardness is unbeatable for wear resistance,” says Dr. Jane Kim, a ceramics expert at CeramTec. This is why we at Eshino Precision love both materials—they solve different problems!

What Makes Each Material Special?

Now, let’s dig into what makes Silicon Nitride and Silicon Carbide so cool. They’re both strong, but they shine in different ways!

Silicon Nitride: The Tough Guy

Silicon Nitride is like a superhero who doesn’t break easily. It’s got a toughness score of up to 6.2 MPa-m^1/2, which means it can take a hit without cracking. Its strength goes up to 2950 MPa, and it’s not as stiff (140-310 GPa), so it bends a little instead of snapping. This makes it perfect for things like engine parts or seals that need to stay strong under pressure.

Silicon Nitride Rod

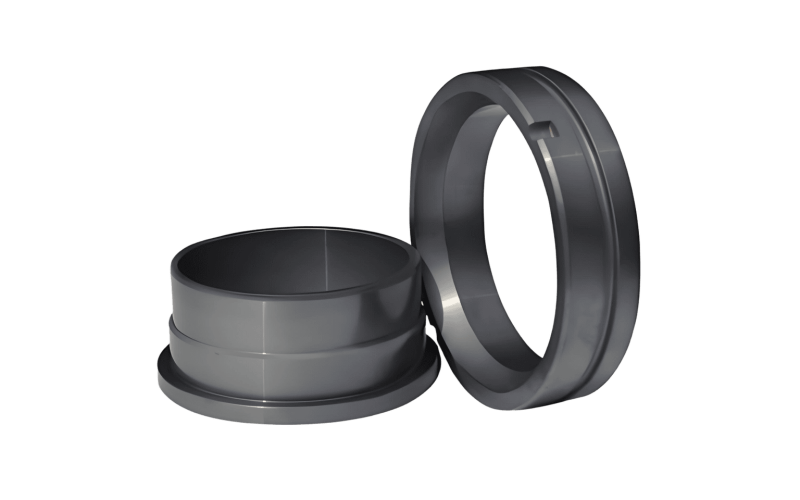

Silicon Nitride Seal

Silicon Carbide: The Hard Hero

Silicon Carbide is like a rock that nothing can scratch. It’s super hard, with a strength of up to 3900 MPa, and it’s really stiff (370-490 GPa). That means it doesn’t bend much, which is great for parts that need to stay solid, like rods or tubes. Plus, it moves heat really well (120-170 W/m-K), so it’s awesome for electronics that get hot.

Silicon Carbide Rod

Silicon Carbide Tube

Which One’s for You?

If your project needs something tough that won’t crack, Silicon Nitride is your buddy. But if you need something hard and great at cooling, Silicon Carbide is the winner. Check out our high-hardness materials page for more details!

How Do They Handle Heat and Chemicals?

Silicon Nitride and Silicon Carbide are both champs at handling tough conditions like heat and chemicals. But they do it in different ways! Let’s break it down so you can see which one fits your needs.

Silicon Nitride: The Heat-Shock Star

Silicon Nitride is awesome when temperatures change fast. Imagine a jet engine heating up and cooling down—it can handle that! It works up to 1600°C in neutral air and 1300°C where there’s oxygen. Plus, it’s got a high thermal shock score (569 K), so it doesn’t crack when things get wild. This makes it perfect for parts like Silicon Nitride tubes in machines that heat up quick. But it’s not as good at moving heat away, with a score of 12-31 W/m-K.

Silicon Carbide: The Heat-Moving Master

Silicon Carbide is like a superhero for steady heat. It stays strong up to 1600°C and moves heat really well (120-170 W/m-K). That’s why it’s great for electronics that need to stay cool! It also fights off acids and alkalis up to 800°C, so it’s tough against chemicals too. This makes it ideal for Silicon Carbide seals in hot, harsh places. “SiC’s ability to dissipate heat is a game-changer for power electronics,” says Dr. Mark Chen, a materials scientist.

Which Wins Here?

If your project has fast heat changes, go with Silicon Nitride. But if you need to keep things cool or fight chemicals, Silicon Carbide is better. Learn more about high-temperature resistance on our site!

Where Are They Used? Real-World Applications

Silicon Nitride and Silicon Carbide show up in cool places! They help make machines and gadgets that we use every day. Here’s where you’ll find them.

Silicon Nitride in Action

Silicon Nitride is the go-to for tough jobs. It’s used in:

- Bearings: Keeps machines spinning smoothly, like in ceramic bearings.

- Cutting Tools: Cuts metal without breaking, see our ceramic cutting tools.

- Turbine Blades: Powers jet engines with strength.

Why? Because it’s tough and doesn’t crack easily, perfect for automotive parts like turbochargers!

Silicon Carbide in the Spotlight

Silicon Carbide shines where hardness matters. You’ll see it in:

- Pump Parts: Resists wear in fluid-handling pumps.

- Rocket Engines: Stays strong in super-hot engines.

- Electronics: Keeps gadgets cool, like in electronics.

Its hardness and heat-moving skills make it a star for new energy tech!

Silicon Nitride Bearing

Silicon Carbide Pump Part

Why This Helps You

Knowing where they’re used helps you pick the right one. Silicon Nitride is for bumpy, tough spots. Silicon Carbide is for hard, hot ones. Check out our applications guide for more ideas!

Cost and How They’re Made

Let’s talk money and making! Silicon Nitride and Silicon Carbide cost different amounts and are made in special ways.

Cost of Silicon Nitride

Silicon Nitride is often pricier per piece because it’s used for special jobs. It’s made by heating powders into a solid shape, called sintering. This takes time and care, so it’s not cheap. But it’s worth it for things like Silicon Nitride bushings that need to last!

Cost of Silicon Carbide

Silicon Carbide costs between $800 and $2000 per ton. That’s more than regular silicon, but it’s made in bigger batches, so the price per part can be lower. It’s formed with high heat too, either by bonding or sintering. This makes it great for big projects like Silicon Carbide rods.

Making Them Work for You

Silicon Carbide is cheaper for big jobs, while Silicon Nitride is better for small, tough ones. Want to save on upkeep? See how ceramics cut costs!

What’s Hot in 2025: Market Trends

In 2025, Silicon Nitride and Silicon Carbide are big news! Here’s what’s happening with them.

Market Size and Growth

Check out this table for the latest:

| Metric | Silicon Carbide (SiC) | Silicon Nitride (Si3N4) |

|---|---|---|

| Market Size (2025) | $3.63 billion | $59.5 million |

| Growth Rate | 10% (to 2030) | 8.3% (to 2032) |

| Big Uses | Electric cars, electronics | Semiconductors, aerospace |

Silicon Carbide is growing fast because of electric cars!

Why This Matters

Silicon Carbide’s market is huge—$3.63 billion—thanks to new energy like EVs. Silicon Nitride is smaller at $59.5 million but growing strong in semiconductors. Both are big in Asia-Pacific, where lots of tech is made!

Conclusion: Picking the Right Ceramic

So, Silicon Nitride vs. Silicon Carbide—which one’s for you? If you need something tough that handles heat shocks, like Silicon Nitride seals for turbines, go with Si3N4. But if you want something hard and great at cooling, like Silicon Carbide tubes for electronics, pick SiC. Match the material to your job, and you’ll win every time!

Ready to get started? At Eshino Precision, we’ve got the perfect ceramic parts for you. Contact us today to find the best Silicon Nitride or Silicon Carbide solution for your project!

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.