Table of Contents

Quick Facts About Silicon Nitride Ceramic

Silicon nitride ceramic is strong, lightweight, and loves heat! Here’s why it’s awesome:

| Feature | Why It Rocks |

|---|---|

| Super Strong | Handles heavy loads without breaking |

| Heat Lover | Stays cool up to 1400°C |

| Lightweight | Perfect for cars and planes |

| Market Boom | $158.38M in 2024, $377.06M by 2037 |

Introduction: Unveiling Silicon Nitride Ceramic

What Is Silicon Nitride Ceramic?

Silicon nitride ceramic is like a superhero material! It’s made from silicon and nitrogen, with a fancy name: Si₃N₄. This stuff is super strong, light, and can handle crazy heat. So, it’s perfect for making things like ceramic rods or seals. At Eshino Precision, we use silicon nitride ceramic to build parts for cars, planes, and even medical tools!

Why It Matters

Why do people love silicon nitride ceramic? Because it works where other materials give up. For example, it’s used in car engines to make them run better. Also, it’s growing fast—the market was $158.38 million in 2024 and could hit $377.06 million by 2037, says Research Nester. That’s a big deal! It shows how much industries trust this material for tough jobs.

Eshino Precision’s Superpower

At Eshino Precision, we’re experts in making silicon nitride ceramic parts. Whether it’s a tube for airplanes or a bearing for machines, we make sure every piece is top-notch. Want to know more? Check out our blog on silicon nitride’s potential!

“Silicon nitride ceramic is the go-to for tough jobs—it’s like the superhero of materials!” says Dr. Emily Carter, a materials scientist at TechCeram Innovations.

Core Properties: Why Silicon Nitride Stands Out

Super Strong and Tough

Silicon nitride ceramic is crazy strong! It has a density of just 3.18 to 3.40 grams per cubic centimeter, so it’s light but tough. Its flexural strength is up to 970 MPa, which means it can hold heavy stuff without breaking. Plus, it’s got a fracture toughness of 8.5 MPa·m^0.5, so it doesn’t crack easily. That’s why we use it for ceramic seals that last forever!

Heat? No Problem!

This material loves heat. It can handle up to 1400°C without melting or bending. Its thermal conductivity is 24 to 28 W/mK, which helps keep things cool. Also, it barely expands when hot—just 1.9 to 3.2 × 10^-6 per Kelvin. This makes silicon nitride ceramic perfect for engine parts in cars.

Extra Cool Features

Silicon nitride ceramic is also great because it stops electricity from flowing, with resistivity up to 10^14 ohm-cm. It fights off acids and other nasty chemicals, too. These traits make it awesome for electronic substrates or parts in chemical plants. Learn more about its strength and corrosion resistance!

Silicon Nitride Rod for Tough Jobs

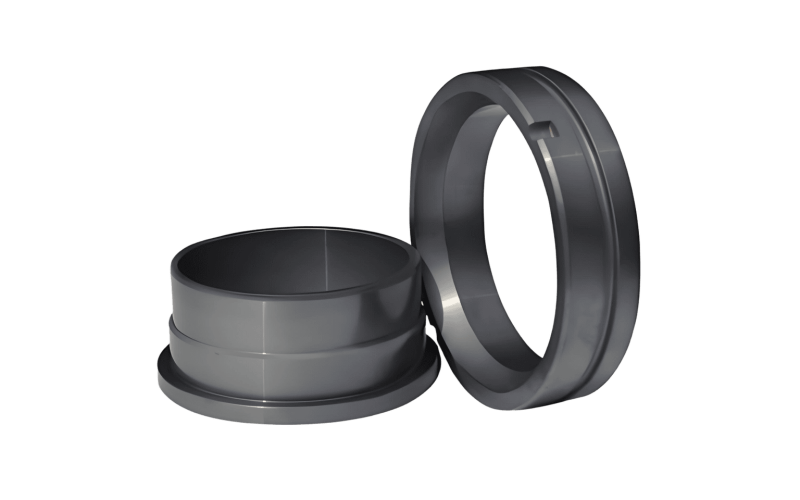

Silicon Nitride Seal for Durability

Types of Silicon Nitride Ceramics: A Breakdown

Reaction-Bonded Silicon Nitride (RBSN)

Reaction-bonded silicon nitride, or RBSN, is made by heating silicon in nitrogen at about 1450°C. It’s a bit porous, around 30%, so it’s not the strongest, but it’s easy to shape. This makes it great for things like refractory materials that don’t need to be super tough. It’s also cheaper, which is awesome for big projects!

Hot Pressed Silicon Nitride (HPSN)

Hot pressed silicon nitride, or HPSN, is super dense because it’s made at 1800°C with lots of pressure. This makes it really strong, perfect for cutting tools that need to last. It costs more, but for high-performance parts like those in machines, it’s worth it.

Sintered and Gas Pressure Sintered (SSN & GPSN)

Sintered silicon nitride (SSN) is made at 1750°C and is the most popular type. It’s strong and versatile, great for bearings or turbine blades. Gas pressure sintered silicon nitride (GPSN) is even tougher, made at 2000°C, and used for valves that face wear. Here’s a quick table:

| Type | Strength | Best Use |

|---|---|---|

| RBSN | Moderate | Refractories |

| HPSN | High | Cutting Tools |

| SSN | Very High | Bearings |

| GPSN | Ultra High | Valves |

How It’s Made: The Manufacturing Process

Starting with Powder

Making silicon nitride ceramic is like baking a super tough cake! First, we need really fine powder made from silicon and nitrogen. This powder is the secret to strong parts, like silicon nitride tubes. At Eshino Precision, we make sure the powder is perfect so our parts, like rods, come out smooth and tough.

Shaping the Pieces

Next, we shape the powder into parts. We might press it, mold it, or even pour it like liquid clay. This creates the rough shape of things like ceramic pins or bushings. It’s kind of like making a sandcastle, but way stronger! These shapes need to be just right for tough jobs in machines.

Making It Solid

Then, we heat the shaped parts to make them hard. There are a few ways to do this:

- Reaction Bonding: Cooks silicon in nitrogen for refractory parts.

- Hot Pressing: Squishes and heats for super dense cutting tools.

- Sintering: Bakes without pressure for bearings.

Each method makes silicon nitride ceramic ready for action. Our team at Eshino Precision picks the best one for parts like seals!

Applications: Where Silicon Nitride Shines

Cars and Trucks

Silicon nitride ceramic is a star in cars! It’s used in engines, bearings, and turbochargers. These parts make cars lighter and faster, especially electric ones. Did you know? About 300,000 turbochargers are made with silicon nitride every year, says Grand View Research. That’s a lot of speedy cars!

Airplanes in the Sky

In airplanes, silicon nitride ceramic makes turbine blades and heat shields. These parts can handle super hot temperatures, so planes fly better and use less fuel. It’s like giving planes a superpower! At Eshino Precision, we make sure these parts are tough enough for the sky.

Helping People

Silicon nitride ceramic is also awesome for medical stuff. It’s safe for the body, so we use it for things like spinal implants or dental parts. It even fights germs, which is super cool for keeping people healthy. Plus, it’s used in electronics and tech gadgets to keep them working in hot spots.

Silicon Nitride Valve for Tough Jobs

Silicon Nitride Plunger for Precision

Advantages: Silicon Nitride vs. Other Materials

Better Than Metal

Silicon nitride ceramic beats metal in lots of ways. It’s lighter, so it’s great for car parts that need to save weight. Also, it doesn’t melt or rust in hot or wet places, unlike metal. This makes it perfect for oil rigs or chemical plants.

Top Dog Among Ceramics

Compared to other ceramics, silicon nitride ceramic is a champ. It’s tougher than alumina, so it doesn’t break as easily. It also handles quick heat changes better than zirconia. That’s why we use it for bushings that need to last. Check out our ceramic comparison!

Special Superpowers

Silicon nitride ceramic has unique tricks. It’s safe for the body, so it’s great for medical implants. It also stops electricity, making it awesome for electronics. These perks make silicon nitride a favorite at Eshino Precision for high-tech projects.

“Silicon nitride’s toughness and versatility make it unbeatable for modern engineering,” says Mark Thompson, a ceramics expert at Precision Tech Innovations.

Market Insights: Trends and Growth

How Big Is It?

Silicon nitride ceramic is making waves! In 2024, its market was worth $158.38 million, and experts think it’ll grow to $377.06 million by 2037. That’s a 6.9% growth rate every year, says Research Nester. Why? Because people love using silicon nitride ceramic for things like rods and bushings in cool industries!

What’s Driving the Boom?

Lots of things are pushing silicon nitride ceramic forward. For example, electric cars need lightweight parts to go faster, and this material is perfect. Also, electronics and medical devices are using it more because it’s strong and safe. But, it’s not all easy—making silicon nitride ceramic can be pricey, which is a challenge we’re working on at Eshino Precision.

Market Snapshot

Here’s a quick look at the numbers:

| Year | Market Size (USD million) | Source |

|---|---|---|

| 2024 | 158.38 | Research Nester |

| 2025 | 176.35 | Research Nester |

| 2037 | 377.06 | Research Nester |

This growth means more ceramic seals and tubes for everyone!

Success Stories: Silicon Nitride in Action

Speedy Cars

Helping Bodies Heal

Flying High

Airplanes love silicon nitride ceramic, too! We’ve crafted turbine blades for jet engines. These blades save fuel because they’re light and strong, handling heat like champs. Companies like CeramTec say they cut engine costs by 10%. That’s a big win for flying!

The Future: Innovations in Silicon Nitride

New and Tougher Stuff

Silicon nitride ceramic is getting even cooler! Scientists are mixing it with other materials to make it stronger for wear-resistant parts. These new versions could be used in valves or bushings that last even longer. At Eshino Precision, we’re excited to try these out!

Cheaper Ways to Make It

Making silicon nitride ceramic can cost a lot, but new tricks are coming. For example, better machines are cutting costs, so more people can use it for machine parts. This means tougher pins or guides without breaking the bank. We’re working on this at Eshino Precision!

Helping Doctors More

In medicine, silicon nitride ceramic might get new coatings that fight germs even better. This could make implants safer. Also, 3D printing is letting us create super fancy custom parts. These ideas could change how we make things, and we’re ready to lead the way!

“The future of silicon nitride is bright, with innovations that’ll make it even more versatile,” says Dr. Sarah Lee, a ceramics specialist at Advanced Materials Lab.

FAQs: Addressing Your Questions

What Is Silicon Nitride Ceramic?

Silicon nitride ceramic is a super strong material made from silicon and nitrogen, called Si₃N₄. It’s tough, light, and loves heat, so it’s used for things like ceramic rods or seals. At Eshino Precision, we make these parts for cars, planes, and more. It’s like a superhero for machines!

What Are the Benefits?

This material is awesome because it’s super durable and doesn’t break easily. It can handle hot places up to 1400°C and stays light, which is great for bearings. Also, it fights off rust and chemicals, perfect for chemical plants. Check out our blog on ceramic advantages to learn more!

Where Is It Used?

Silicon nitride ceramic pops up everywhere! It’s in car engines, airplane turbines, and even medical implants. It’s also used in electronics to keep gadgets safe and cool. Basically, anywhere that needs tough, reliable parts loves this material!

How Does It Compare?

Compared to other ceramics, silicon nitride ceramic is a champ. It’s tougher than alumina and handles heat changes better than zirconia. It’s also lighter than metals, making it great for cars. Want details? See our comparison guide!

Conclusion: Partner with Eshino Precision

Why Silicon Nitride Rocks

Silicon nitride ceramic is like a magic material! It’s super strong, light, and can handle heat, making it perfect for electronics, airplanes, and medical tools. At Eshino Precision, we use it to make awesome parts like bushings and valves. Plus, its market is growing fast—$158.38 million in 2024 to $377.06 million by 2037!

More Cool Resources

Want to dive deeper? Here are some great places to learn more about silicon nitride ceramic:

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.