Advanced ceramic materials with exceptional wear resistance can significantly reduce component failure, downtime, and maintenance costs. Discover how these ceramics stand up to friction, abrasion, and erosion in the toughest applications.

Wear resistance refers to a material’s ability to maintain its surface integrity when in contact with abrasive particles, repetitive friction, or corrosive media. Ceramics renowned for wear resistance often maintain their dimensions and surface finish far longer than metals or polymers under similar conditions.

Why It Matters:

Extended Service Life

Components made of highly wear-resistant ceramics require fewer replacements, translating into lower operating expenses and improved ROI.

Reduced Downtime

Abrasion and friction-induced damage often lead to unexpected shutdowns. Wear-resistant ceramics drastically cut the frequency of maintenance outages.

Enhanced Process Efficiency

When parts retain their original form and smoothness, machinery can run at optimal throughput without performance deterioration.

Consistent Product Quality

In processes like grinding, mixing, or fluid handling, dimensional stability of wear parts ensures uniform product outcomes and tighter tolerances.

Hardness & Microstructure

Generally, higher hardness correlates with better wear resistance. A dense, fine-grained microstructure also reduces crack formation and surface damage.

Phase Composition & Toughening

Advanced ceramics, such as silicon carbide (SiC) or zirconia (ZrO₂), may incorporate special toughening mechanisms (e.g., transformation toughening in zirconia) to combat micro-cracks under friction or impact loads.

Surface Engineering

Specialized coatings, polishing, or finishing processes can further boost wear performance by smoothing out potential weak points where abrasive particles may catch or accumulate.

Pin-on-Disk / Ball-on-Disk Tests (ASTM G99)

Taber Abrasion Test (ASTM D4060)

Dry Sand / Rubber Wheel Test (ASTM G65)

Below is a representative table comparing typical wear-related properties of various ceramics. Actual performance will vary based on exact composition, microstructure, and manufacturing process.

| Material | Typical Hardness (HV) | Fracture Toughness (MPa·m^1/2) | Wear Rate (Relative) | Density (g/cm³) |

| Zirconia (ZrO₂) | 1,000 – 1,500 | 7 – 10 | Low – Moderate | 5.6 – 6.1 |

| Alumina (Al₂O₃) | 1,500 – 2,000 | 3 – 4 | Low | 3.8 – 4.0 |

| Silicon Nitride (Si₃N₄) | 1,400 – 1,800 | 5 – 7 | Low | 3.1 – 3.3 |

| Silicon Carbide (SiC) | 2,500 – 3,200 | 3 – 4 | Very Low | 3.1 – 3.2 |

Key Takeaways:

Still unsure which material is best? Get a free recommendation.

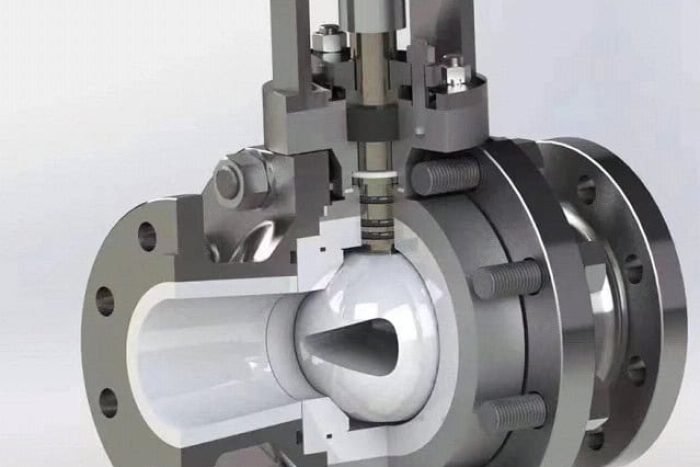

Pump Components & Valves

Mechanical Seals & Bearings

Mining & Mineral Processing

Paper & Pulp Industry

Challenge:

A pulp mill replaced steel rollers every few months due to abrasive wear from wood pulp and chemical additives, causing regular downtime.

Solution:

They adopted alumina-ceramic coated rollers for the most wear-intensive sections.

Outcome:

Explore More Case Studies or Contact Us to discuss a solution tailored to your industry.

We provide turnkey solutions for wear-resistant ceramic components, from initial material selection to precise finishing and quality checks.

Diverse Material Options

Advanced Forming & Sintering

Precision Machining & Polishing

Comprehensive Quality Control

Engineering & After-Sales Support

They’re related but not identical. High hardness generally contributes to wear resistance, but fracture toughness, lubrication, and specific wear mechanisms (abrasive, adhesive, erosive) also play critical roles.

Abrasive wear usually involves hard particles grinding against the surface, while erosive wear occurs when particles strike at speed (e.g., in fluids or gas streams). Silicon carbide may excel in abrasive conditions, while zirconia or silicon nitride might better handle impact loads. We can guide you based on your exact environment.

For combined corrosion and abrasion, SiC and certain zirconia grades are often used. Chemical compatibility is crucial—our team can match the ceramic’s chemistry to resist both corrosion and wear simultaneously.

Yes, ceramic coatings (e.g., alumina or tungsten carbide-based) can be applied to metallic substrates. However, a fully ceramic component may offer better long-term performance, especially in severe conditions. Contact us to explore both approaches.

Many clients run their own pilot tests using pin-on-disk or custom wear simulators under actual process conditions. We also provide test coupons or small sample batches to help you benchmark performance.

Depending on complexity, lead times can range from 4 to 8 weeks. Prototyping might be faster if we have standard tooling or shapes available.

Still have more questions?

Send us an inquiry or check out our blog for deeper dives into ceramic materials and industry trends.

Our advanced wear solutions can drastically cut maintenance costs and keep your operations running smoothly. Let’s pinpoint the ideal ceramic or coating for your specific challenges.

We will get back to you within 12 hours.