In many industrial and high-tech environments, controlling heat flow is crucial. Discover how advanced ceramics with low thermal conductivity offer excellent thermal insulation, reducing heat loss and protecting vital components from extreme temperature gradients.

Low thermal conductivity refers to a material’s inability to efficiently transfer heat across its structure. The lower the thermal conductivity, the better the material can insulate against temperature changes, preserve energy, and prevent heat-related damage. Advanced ceramics with low thermal conductivity excel in applications requiring thermal barriers or temperature isolation.

Why It Matters:

Energy Efficiency

By minimizing heat transfer, these ceramics help maintain stable temperatures, reducing energy consumption in furnaces, kilns, or high-temperature processes.

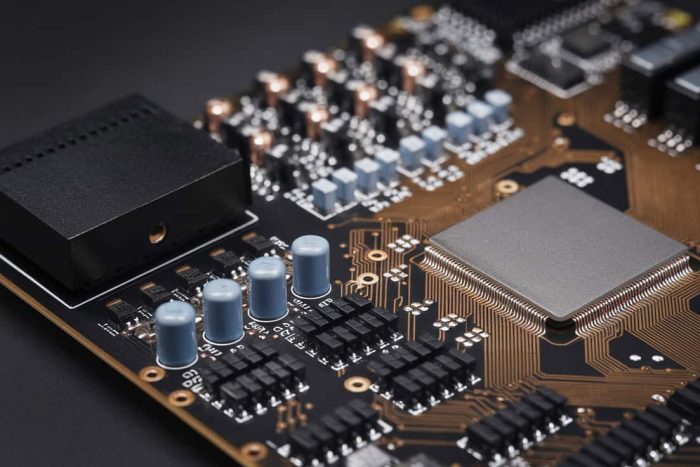

Protection of Sensitive Components

In electronics or aerospace, controlling the heat environment prolongs component lifespan and prevents overheating, which can lead to failures or costly downtime.

Enhanced Safety

Thermal insulation prevents burns or thermal shocks to operators in industrial settings, improving workplace safety and equipment reliability.

Cost Savings Over Time

Although specialized ceramics may have a higher initial cost, reducing energy losses and protecting machinery from heat damage often yields a strong ROI.

Stable Crystalline Structure

Many ceramics (e.g., certain zirconia formulations) have lattice structures that limit phonon movement (heat conduction) through the crystal.

Porous or Engineered Microstructure

Controlled porosity or special composite designs can trap air pockets, drastically lowering heat conduction.

Thermal Barrier Coatings (TBCs)

Some advanced ceramics serve as coatings on metals or other substrates, creating a thermal barrier layer that prevents heat penetration.

Thermal Conductivity Measurement (ASTM E1461 – Laser Flash Method)

Guarded Hot Plate or Heat Flow Meter (ASTM C177, C518)

Thermal Diffusivity & Specific Heat Tests

Below is a representative table showcasing typical low thermal conductivity ceramics. Actual performance varies by purity, microstructure, and processing techniques.

| Material | Thermal Conductivity (W/m·K) | Temp Range (°C) | Notable Features | Density (g/cm³) |

| Zirconia (ZrO₂) | ~2.0–3.0 | Up to 1000+ | Excellent insulation, can be toughened | 5.6 – 6.1 |

| Alumina (Al₂O₃) | ~18–30 | Up to 1700+ | Good mechanical strength, cost-effective | 3.8 – 4.0 |

| Silicon Nitride (Si₃N₄) | ~15–20 | Up to 1200+ | Moderate insulation, high strength | 3.1 – 3.3 |

| Mullite (3Al₂O₃·2SiO₂) | ~3–6 | Up to 1600+ | Known for low expansion, good insulation | ~2.8 – 3.0 |

Key Takeaways:

Still unsure which material is best? Get a free recommendation.

Thermal Barriers in Turbine Engines

Refractory Linings & Furnace Insulation

Electronics & Semiconductor Processing

Automotive & E-Mobility

Challenge:

A ceramic tile producer saw high energy expenses and extended furnace run times due to significant heat loss in their kilns.

Solution:

They upgraded their furnace linings to a mullite-based insulation with excellent low thermal conductivity.

Outcome:

Explore More Case Studies or Contact Us to discuss a solution tailored to your industry.

We provide end-to-end solutions for low thermal conductivity ceramics, covering material selection, precision shaping, and quality validation.

Material Engineering & Custom Formulations

Advanced Forming & Sintering

Precision Machining & Coating

Comprehensive Quality Assurance

Expert Consultation & Design Support

Low thermal conductivity means the material doesn’t easily transfer heat, acting as an insulator. Thermal shock resistance measures how well a material handles sudden temperature changes without cracking. Some ceramics (like silicon nitride) offer both properties, but they’re not identical concepts.

It depends on the material composition and microstructure. For instance, zirconia can be toughened to mitigate brittleness, while other low-k ceramics may require design considerations to accommodate mechanical stress.

Though advanced ceramics can be more expensive upfront, they often deliver long-term savings via energy efficiency, reduced maintenance, and improved product quality. We can provide a custom cost-benefit analysis based on your application.

Yes, hybrid assemblies are common—ceramics might serve as insulation layers, while metals handle structural loads. We’ll help ensure thermal expansion differences don’t cause stress or failure at joints.

We offer various shapes, tiles, bricks, or coatings. Our team can guide you on modular installation, sealing, and recommended adhesives or mechanical fixings for large-scale setups.

Depending on complexity, lead times can range from 4 to 8 weeks. Prototyping might be faster if we have standard tooling or shapes available.

Still have more questions?

Send us an inquiry or check out our blog for deeper dives into ceramic materials and industry trends.

Enhance energy efficiency and protect sensitive systems with low thermal conductivity ceramics. Let us design a tailored insulation solution that meets your performance and budget needs.

We will get back to you within 12 hours.

We will be in touch within 12 hours. Your intellectual property is 100% secure with us.