Discover how our high-hardness ceramics extend the lifespan of critical components, reduce maintenance costs, and improve performance in industries like manufacturing, mining, and electronics.

High hardness refers to a material’s ability to resist indentation, scratching, or surface deformation. Unlike metals, which might dent under stress, ceramics with high hardness maintain their surface integrity, even in abrasive or high-friction conditions.

Why It Matters:

Extended Wear Life

Harder surfaces reduce wear rates and abrasion, resulting in fewer replacements and lower maintenance costs.

Improved Operational Reliability

Components that retain their shape and dimensions under high loads help ensure consistent performance in industrial processes or precision mechanisms.

Lower Friction & Enhanced Efficiency

High hardness often pairs with smooth surfaces and stable lubrication, potentially minimizing frictional losses in rotating or sliding parts.

Better Surface Finishes

For applications like cutting tools or molds, a high-hardness ceramic can maintain a precise edge or detailed surface, improving final product quality.

Crystalline Structure & Bonding

Most advanced ceramics (e.g., silicon carbide, alumina) have strong ionic or covalent bonds, giving them inherently high hardness values.

Fine Grain Size & Dense Microstructure

Reducing grain size and minimizing porosity in the sintering process leads to higher hardness. A dense microstructure ensures fewer weak points for cracking or chipping.

Advanced Manufacturing Techniques

Techniques like hot pressing, HIP (Hot Isostatic Pressing), or pressureless sintering can further enhance hardness by achieving near-theoretical density.

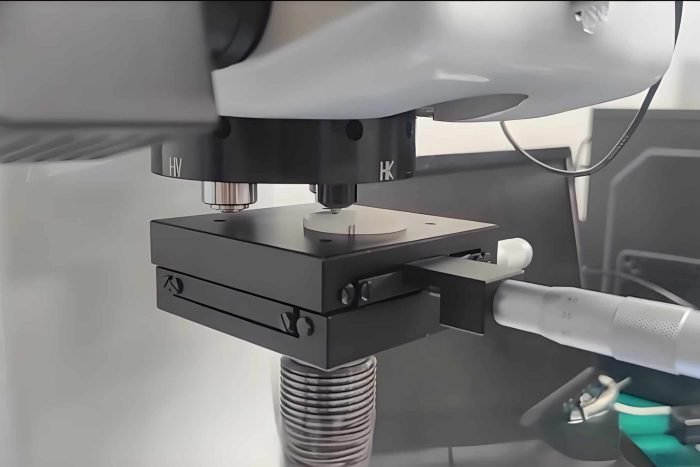

Vickers Hardness (HV)

Rockwell Hardness (HR)

Knoop Hardness (HK)

Below is a representative table comparing typical hardness ranges among various advanced ceramics. Actual figures may vary based on composition and manufacturing routes.

| Material | Typical Vickers Hardness (HV) | Fracture Toughness (MPa·m^1/2) | Density (g/cm³) |

| Silicon Carbide (SiC) | 2,500 – 3,200 | 3 – 4 | 3.1 – 3.2 |

| Alumina (Al₂O₃) | 1,500 – 2,000 | 3 – 4 | 3.8 – 4.0 |

| Silicon Nitride (Si₃N₄) | 1,400 – 1,800 | 5 – 7 | 3.1 – 3.3 |

| Zirconia (ZrO₂) | 1,000 – 1,500 | 7 – 10 | 5.6 – 6.1 |

Key Takeaways:

Still unsure which material is best? Get a free recommendation.

Cutting Tools & Machining

Wear-Resistant Linings & Coatings

Mechanical Seals & Bearings

Aerospace & Defense

Challenge:

A mineral processing plant struggled with frequent wear on metal grinding media, leading to shutdowns for replacement and high material costs.

Solution:

Switching to high-hardness alumina grinding media significantly reduced abrasion inside the grinding mills.

Outcome:

Explore More Case Studies or Contact Us to discuss a solution tailored to your industry.

We offer end-to-end solutions for high-hardness ceramic components—from material selection to final finishing and quality assurance.

Wide Material Portfolio

State-of-the-Art Production

Precision Finishing

In-House Testing & Quality Control

Expert Team Support

While they’re closely related, hardness measures resistance to surface indentation, whereas wear resistance is a broader concept involving material loss over time. High hardness typically contributes to wear resistance, but other factors (like toughness, lubrication, and particle size in abrasive media) also matter.

Silicon carbide typically offers higher hardness and better thermal conductivity, making it more suited for extreme wear or thermal conditions. Alumina is often more cost-effective and still provides strong performance. Your choice depends on budget, thermal factors, and the specific abrasives or loads in your application.

Some do—like silicon nitride and toughened zirconia, which balance hardness with improved fracture toughness. However, very hard materials can be brittle. Discuss your impact and loading requirements with our engineers to select the right balance.

In many machining processes, ceramic inserts outperform carbide in terms of hardness and thermal stability. Still, the decision often depends on the workpiece material, feed rates, and cutting environment. We can provide comparative data and samples to help you evaluate feasibility.

Absolutely. Many high-hardness ceramics—like SiC and Si₃N₄—retain their hardness at high temperatures. If you need combined heat and wear resistance, we recommend a detailed review of thermal shock requirements alongside hardness.

Depending on complexity, lead times can range from 4 to 8 weeks. Prototyping might be faster if we have standard tooling or shapes available.

Still have more questions?

Send us an inquiry or check out our blog for deeper dives into ceramic materials and industry trends.

Empower your products and processes with long-lasting, wear-resistant ceramic components. Let us guide you in selecting and manufacturing the perfect high-hardness solution for your needs.

We will get back to you within 12 hours.

We will be in touch within 12 hours. Your intellectual property is 100% secure with us.