High-performance Ceramic Components

Factory Direct

ODM & OEM are avaliable

All queries will be replied in 12 hours

With sample to check before production

The ceramic with the best toughness

High strength, high hardness, high toughness, high temperature resistance, wear resistance, corrosion resistance; no signal shielding, good chemical stability, strong machinability, good appearance

The most cost-effective ceramic material

High strength, high hardness, high temperature resistance, wear resistance, corrosion resistance, oxidation resistance, insulation, non-magnetic

The ceramic with excellent overall performance

High hardness, high strength, high temperature resistance, wear resistance, corrosion resistance, anti-adhesion, low coefficient of friction, self-lubrication

An ultra-hard ceramic material

Heat resistance, thermal stability, thermal conductivity, high temperature dielectric strength, good chemical stability, can resist the erosion of most molten metals, self-lubrication

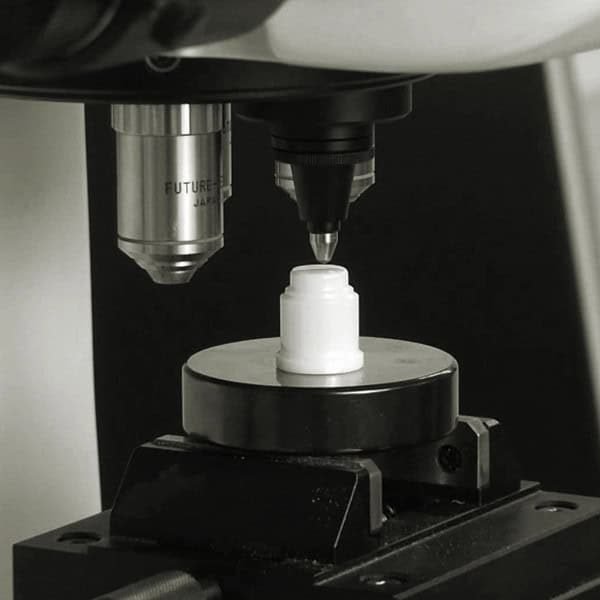

ESHINO's pRECISION

Concentricity

0.001MM

Cylindricity

0.001MM

Parallelism

0.001MM

Cylindricity

0.001MM

Hole Depth Accuracy

0.001MM

Surface Roughness

ra0.01

Internal Threads

m1.6

Material Performance Sheet

| Type | Unit | Test Standard | Alumina | Zirconia | Silicon Carbide | Silicon Nitride | |||||

| Material | Al₂O₃ 96% | Al₂O₃ 97% | Al₂O₃ 99.7% | Al₂O₃-ZrO₂ | ZrO₂-Y₂O₃ | ZrO₂-Mgo | Mg-Psz | SiC | Si₃N₄ | ||

| Colour | white, ivory | white, ivory | white, ivory | yellow | white | yellow | white | black | black | ||

| Density | g/cm³ | ISO18754:2003 | 3.6 | 3.65 | 3.9 | 4.2 | 5.95-6 | 5.65 | 5.7 | 3.15 | 3.2 |

| Flexural Strength | Mpa | ASTM-C1161-13 | 310 | 360 | 400 | 500 | 1000 | 480 | 580 | 400 | 700 |

| Compressive Strength | Mpa | GB/T8489-2006 | 2200 | 2250 | 2450 | 2700 | 2200 | 1600 | 1600 | 2000 | 3000 |

| Modules of Elasticity (young) | Gpa | ASTM-C1198-09 | 300 | 330 | 380 | 350 | 210 | 210 | 210 | 430 | 290 |

| Fracture Toughness | MPa*m1/2 | ASTM-C1421-18 | 3.5 | 3.5 | 4 | 3.5 | 8 | 6 | 7 | 4 | 6 |

| Poision’s Ratio | ASTM-C1421-18 | 0.22 | 0.23 | 0.22 | 0.24 | 0.3 | 0.3 | 0.3 | 0.16 | 0.28 | |

| Hardness HRA | HRA | RICKWELL 60N | 88 | 90 | 91 | 91 | 90 | 88 | 88 | 94 | 91.5 |

| Vickers Hardness | HV1 | ASTM-C1327-15 | 1250 | 1450 | 1600 | 1600 | 1450 | 1200 | 1200 | 2100 | 1600 |

| Thermal Expansion Coefficient | 10-6K-1 | ASTM-E1461-13 | 7.2 | 7.1 | 6.8 | 9.2 | 10 | 9 | 9 | 3.5 | 3.2 |

| Thermal Conductivity | W/mk | ASTM-E1461-13 | 24 | 25 | 32 | 8 | 3 | 3 | 3 | 90 | 30 |

| Thermal Shock Resistance | △T.℃ | / | 200 | 200 | 220 | 470 | 400 | 400 | 400 | 600 | 600 |

| Max Use Temperature in Oxidizing Atmosphere | ℃ | NO LOAD CONDITION | 1000 | 1000 | 1200 | 1000 | 1000 | 1000 | 1000 | 1350 | 1300 |

| Max use Temperatur in reducing or Inert Atmosphere | ℃ | NO LOAD CONDITION | 1000 | 1000 | 1400 | 1000 | 1000 | 850 | 850 | 1350 | 1400 |

| Volume Resistivity at 20°C | Ωcm | / | 1014 | 1014 | 1015 | 1014 | 1012 | 5X1013 | 5X1013 | 105 | 1014 |

| Dielectric Strength | kV/mm | / | 13 | 16 | 20 | 16.5 | 15 | 19 | 19 | 0 | 15 |

| Dielectric Constant (1MHN) | ASTM-D2149-13 | 9.5 | 9.5 | 9.5 | 10 | 30 | 27 | 27 | / | 9 | |

| Dielectric Loss Angle at 20C, 1MHz | tanδ | ASTM-D2149-13 | 3X10-4 | 3X10-4 | 1X10-4 | 2X10-4 | 2X10-3 | 2X10-3(1GHz) | 2X10-3(1GHz) | / | 4X10-3 |

| Material | Hardness | Strength | Thermal Conductivity | Electrical Insulation | Wear-resistance | High-Temperature Resistance | Corrosion Resistance |

| Al2O3 | High | High | Middle | High | High | High | Middle |

| ZrO2 | Middle | High | Low | Middle | High | Middle | Middle |

| Si3N4 | High | High | Middle | Middle | High | High | High |

| SiC | High | High | High | Low | High | High | High |

CONNECT US NOW TO MAKE SOME SERIOUS $$$$

ODM & OEM Services

Most of our products are customized, if necessary, we could be your technician to help to push projects.

Premium Supplies

Using high-quality materials for ceramic part manufacturing guarantees durability, reliability, and longevity.

Quality Guranteed

Have strict quality control measures in place to ensure that every part we produce meets our high standards and with satisfaction guarantee.

Up-To-Date Trends

Keep up with industry trends and advancements by researching and testing new materials and techniques to improve our products and services.

Our Happy Clients From 30+ Countries

Reach Your FULL Potential Now!

We’d love to hear from you! Send us a message using the form opposite, or email us. We’d love to hear from you! We will get back to you within 12 hours.