Table of Contents

Wow! Did you know ceramic materials can make batteries safer and pack more power? At Eshino Precision, we’re amazed by how they help. Check out this cool table to see why they’re awesome for batteries:

| Property | Ceramics | Metals | Polymers |

|---|---|---|---|

| Ionic Conductivity | High | Low | Moderate |

| Thermal Stability | Excellent | Good | Poor |

| Chemical Resistance | Excellent | Poor to Good | Poor |

| Strength | High | High | Low |

Let’s dive into how ceramic materials are used in battery technology!

Introduction to Ceramic Materials in Battery Technology

What Are Ceramic Materials?

Ceramic materials are hard, tough things like alumina and silicon nitride. They’re not metal, but they’re super strong and don’t melt easily.

Why Batteries Need Them

Batteries power cars, phones, and even big energy grids. But sometimes, they get hot or break. So, how ceramic materials are used in battery technology helps make them safer and better—check New Energy Uses.

How They Help

Ceramics keep batteries from catching fire, store more energy, and last longer. They’re like superheroes for battery power—see Ceramic Superheroes.

Big Market News

In 2025, ceramics are worth $262.83 billion. Experts say they’ll hit $406.42 billion by 2032 because how ceramic materials are used in battery technology is growing fast. That’s a big deal for cars and green energy!

Key Properties of Ceramics for Battery Applications

Fast Ion Moving

Ceramics let tiny bits called ions zip through fast. This helps batteries charge quick—see Electrical Insulation.

Heat Fighters

They can handle super hot stuff—up to 1900°C with alumina. So, batteries stay safe even when they heat up—check Heat Resistance.

No Rust Ever

Ceramics don’t rust or break down in battery juice. Dr. Sarah Kim, a battery expert, says, “How ceramic materials are used in battery technology keeps them strong where others fail.” Learn more at Corrosion Resistance.

Really Strong

They’re tough and don’t crack easy. This keeps battery parts solid—see High Strength.

Quick Look Table

| Property | Ceramics | Metals |

|---|---|---|

| Ionic Conductivity | High | Low |

| Thermal Stability | Excellent | Good |

Types of Ceramic Materials Used in Batteries

Ceramic Electrolytes

These replace runny liquids in batteries. Sodium beta aluminas work in hot batteries, and lithium ones like LiPON help solid-state batteries—check Oxide Ceramics.

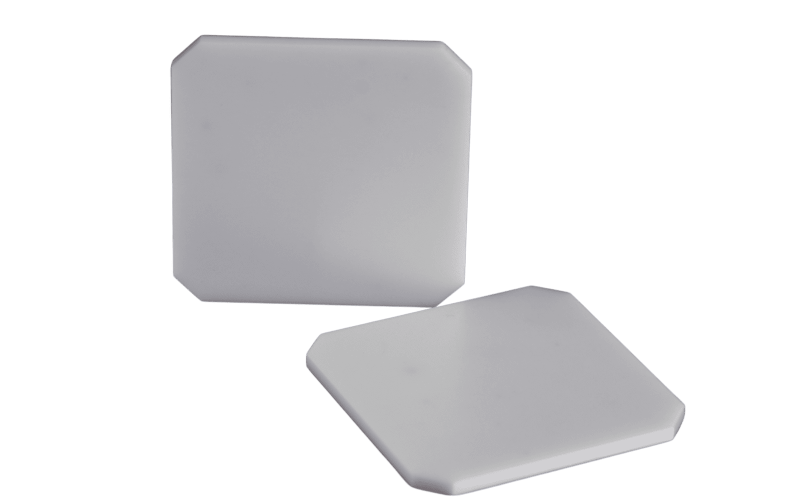

Ceramic Separators

Alumina coats keep battery parts apart and safe. They stop short circuits in lithium-ion batteries—see Ceramics 101.

Ceramic Electrodes

Stuff like lithium cobalt oxide powers batteries up. Lithium iron phosphate lasts over 2000 charges—learn more at Ceramic Properties.

More Cool Ones

Titanium dioxide makes batteries steady and safe. How ceramic materials are used in battery technology keeps them rocking—check Non-Oxide Ceramics.

Types of Ceramic Materials Used in Batteries

Solid-State Batteries

These use ceramics instead of liquid to stay safe. They’re the future for cars—see Automotive Uses.

Lithium-Ion Batteries

Ceramics make regular batteries tougher and safer. Alumina separators stop fires—check Electronics Impact.

Sodium-Sulfur Batteries

They run hot at 350°C for big energy grids. Ceramics keep them going strong—see Energy Storage.

Electric Cars

How ceramic materials are used in battery technology gives cars more miles. Toyota’s working on it—check Ceramics’ Impact.

Green Energy Grids

Ceramics store sun and wind power. They’re super tough for big systems—see Ceramic Benefits.

Ceramic Electrolyte - Safe Power

Ceramic Separator - No Fires

Advantages of Using Ceramics in Batteries

Super Safe

How ceramic materials are used in battery technology makes them way safer. They replace runny stuff that can catch fire with solid ceramics—check High Reliability.

More Power

Ceramics pack more energy—like 500 Wh/kg instead of 250 Wh/kg in regular batteries. That means longer-lasting power for phones and cars—see Ceramic Applications.

Lasts Longer

They keep going for over 2000 charges. Lithium iron phosphate, a ceramic, is tough and cuts replacement costs—learn more at Cost Savings.

Hot Stuff Ready

Ceramics work great up to 350°C. This helps batteries in hot spots or fast charging—see Ceramic Advantages.

Challenges and Future Trends

Tricky Connections

Sometimes, ceramics don’t stick well to other battery parts. This can slow things down, but experts are fixing it—check Precision Components.

Costs a Bit More

Making ceramics can be pricey. But new ways like 3D printing might make them cheaper soon—see Custom Parts.

Cool New Ideas

Mixing ceramics with plastics makes awesome batteries. How ceramic materials are used in battery technology is getting better—check Ceramics’ Impact.

Green Energy Future

Ceramics will store sun and wind power better. They’re set to grow big by 2032—learn more at New Energy.

Case Studies and Real-World Examples

NGK’s Grid Power

NGK uses ceramics in sodium-sulfur batteries for energy grids. They’ve been rocking it since the 1990s—see Ceramics 101.

Toyota’s Car Plan

Toyota’s making ceramic batteries for cars by 2025. How ceramic materials are used in battery technology could double car miles—check Automotive Uses.

QuantumScape’s Big Win

QuantumScape’s ceramic batteries might double EV range. They’re a hot topic in 2025—see Ceramic Benefits.

Real-Life Proof

These show how ceramic materials are used in battery technology works. They’re making batteries awesome—learn more at Structural Ceramics.

Conclusion

Why Ceramics Rock

How ceramic materials are used in battery technology is amazing! They stop fires, pack more power, last long, and handle heat. This helps cars, phones, and green energy.

We’re the Experts

At Eshino Precision, we make ceramic parts like substrates and rods. We’re here to power your batteries!

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.