Table of Contents

Here’s a cool fact: Ceramic gears can last way longer than metal gears, cutting down repair time and making machines run better! At Eshino Precision, we make these awesome gears to help machines in cars, planes, and even medical tools work smoothly. Check out this quick table to see why ceramic gears rock:

| Feature | Ceramic Gears | Metal Gears |

|---|---|---|

| Wear Out? | Super Slow | Faster |

| Heat Handling | Up to 2000°C | Much Less |

| Weight | Lighter | Heavier |

Now, let’s dive in and see how ceramic gears make machines amazing!

Introduction to Ceramic Gears

What Are Ceramic Gears?

Ceramic gears are special parts that help machines move. They’re made from tough stuff like alumina, silicon nitride, and zirconia. So, they spin and push power from one part of a machine to another, like a superhero team passing energy!

Why Do Machines Need Them?

Machines get hot and wear out. Ceramic gears, though, stay strong even in tough spots. For example, in cars or electronics, they keep things running without breaking down. Plus, they’re getting super popular because they’re so good at their job.

How Are They Different?

Unlike metal gears, ceramic gears don’t rust or melt easily. They’re perfect when things get really hot or messy. At Eshino Precision, we craft these gears to fit your needs, like our custom ceramic parts. Want to learn more? Check out What Are Structural Ceramics?.

A Big Deal in 2025

In 2025, ceramic gears are a big deal. The ceramics market is growing fast—it might hit $107 billion by 2030! That’s because more people want machines that last longer and work better, and ceramic gears deliver.

Why Ceramic Gears Stand Out: Key Properties

What Makes Them Special?

Ceramic gears have cool features that make them awesome. They’re super hard, strong, and light. Also, they handle heat like champs. Here’s a simple table to show you:

| Material | Hardness | Strength | Weight | Heat Handling | Max Temp |

|---|---|---|---|---|---|

| Alumina | Very High | High | Light | Good | 1750°C |

| Silicon Nitride | High | Very High | Very Light | Moderate | 1400°C |

| Zirconia | Moderate | High | Heavier | Excellent | 2000°C |

Hard and Strong

Hardness means ceramic gears don’t wear out fast. For instance, alumina’s hardness keeps them tough. Strength, like in silicon nitride, lets them carry heavy loads without breaking.

Light and Hot

They’re lighter than metal, so machines use less energy. Also, they work in super-hot places—up to 2000°C with zirconia. See more at High-Temperature Resistance.

Why It Matters

These properties make machines faster and stronger. Whether it’s a car engine or a robot, ceramic gears keep things going without trouble.

Advantages of Ceramic Gears Over Metal Gears

They Last Longer

Ceramic gears don’t wear out quickly. So, in a machine with lots of spinning, they stay good for years. This cuts repair time, as explained in How Ceramic Materials Reduce Costs.

Great in Heat

Metal gears melt or weaken in heat, but ceramic gears don’t. For example, in jet engines at 1000°C, they keep working fine. That’s a big win for car parts!

No Rust, Less Oil

Ceramic gears don’t rust, even in wet or chemical-filled places. Plus, they need less oil to run smoothly. This is perfect for chemical plants.

Light and Safe

They’re lighter, so machines move easier and use less power. Also, they don’t conduct electricity, making them safe for electronics. Dr. Jane Lee, a gear expert, says, “Ceramic gears cut weight and boost safety, transforming how machines perform in tough spots.”

Where Ceramic Gears Shine: Applications

Cars Love Them

In cars, ceramic gears help engines and turbochargers run better. They’re light and tough, saving fuel and lasting longer.

Planes Use Them

For airplanes, ceramic gears lighten engines and handle heat. This makes flights more efficient and safe.

Electronics Need Them

In electronics, they’re in robots and tools. Their no-electricity feature keeps things safe and precise.

More Cool Uses

Chemical plants use them in pumps because they don’t rust. Also, medical tools use them since they’re safe for bodies. Check our ceramic rods for examples!

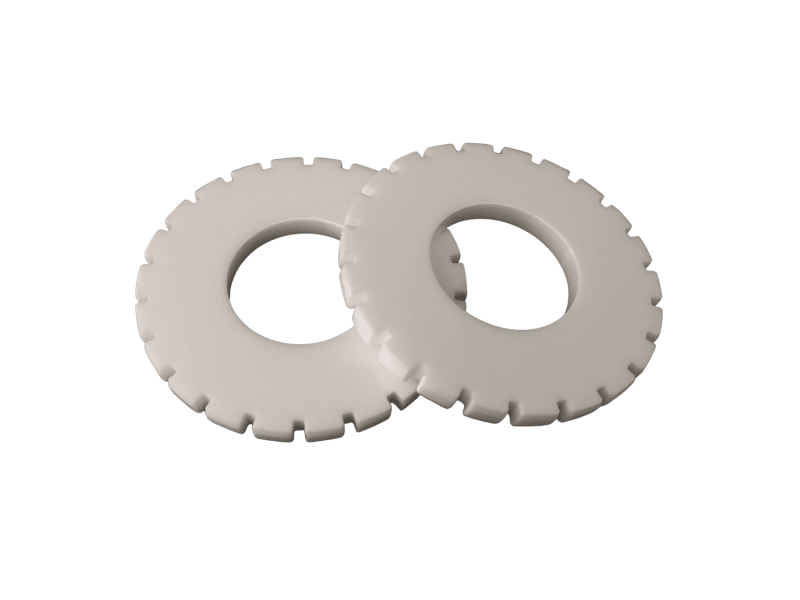

Alumina Gear - Super Tough

Silicon Nitride Gear - Light and Strong

Real-World Proof: Case Studies

Cars Get a Boost

Ceramic gears make cars run better! For example, a big car company swapped old steel gears for silicon nitride ceramic gears in their turbochargers. So, the engine worked 30% better and needed 50% less fixing. That’s because ceramic gears don’t wear out fast, even in hot, spinning parts.

Planes Fly Smarter

Robots Work Better

In electronics, a robot company added zirconia ceramic gears. These gears kept things precise and didn’t break down often. Plus, they don’t carry electricity, so the machines stayed safe. Learn more in our electronics blog.

Why It’s Awesome

These stories show ceramic gears really help machines. At Eshino Precision, we can make gears like these for you. Check out our ceramic substrates to see how we do it!

Challenges and What’s Next

They Can Break

Ceramic gears are super tough, but they’re brittle. So, if something hits them hard, they might crack. That’s a challenge in rough machines, as noted in Brittleness and Toughness.

They Cost More

Making ceramic gears isn’t cheap. They need special tools and time, so they cost more than metal gears at first. However, they save money later because they last so long. See how ceramics cut costs.

Designing Them Right

Ceramic gears need careful planning to avoid breaking. Engineers work hard to make them perfect. At Eshino Precision, we’re experts at this, using our ceramic parts.

Cool Stuff Coming

The future looks bright for ceramic gears! New mixes make them tougher. Also, 3D printing cuts costs and makes cool shapes. Plus, the ceramics market might hit $107 billion by 2030. We’re ready with advanced ceramics.

Your Questions Answered: FAQs

What Are Ceramic Gears Made Of?

They’re made from strong stuff like alumina, silicon nitride, and zirconia. Each one’s great for different jobs.

Why Pick Ceramic Over Metal?

Ceramic gears last longer, handle heat, and are lighter. They’re perfect for tough spots, unlike metal gears that wear out faster.

Where Do They Go?

You’ll see them in cars, medical tools, and electronics. They fit lots of machines!

Are They Expensive?

Yes, they cost more to start. But, they save cash over time with less fixing. Check High Reliability for more.

Can They Take Heat?

Totally! Ceramic gears work up to 2000°C, way hotter than metal can handle.

How Light Are They?

They’re lighter than steel, making machines easier to run. See Lightweight benefits.

Do They Last Long?

Yes, ceramic gears keep going thanks to their wear resistance. They’re built to last!

Conclusion

Why Ceramic Gears Rock

Ceramic gears make machines better in so many ways. They’re tough, light, and handle heat like pros. So, they last longer, cut repair time, and boost how well machines work. From cars to planes, ceramic gears are changing the game.

Eshino Precision Has You Covered

At Eshino Precision, we’re experts at making ceramic gears that fit your needs. Whether it’s alumina rods or silicon nitride parts, we’ve got the best solutions.

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.