Table of Contents

Wow, did you know engineering ceramics are growing super fast? They’re tough materials that help cars, planes, and even teeth work better! In 2023, their market was $6.76 billion, and by 2025, it’s hitting $7.42 billion. Check out this cool table to see how big they’re getting!

| Year | Market Size (USD Billion) |

|---|---|

| 2023 | 6.76 |

| 2025 | 7.42 |

| 2032 | 10.3 |

Why They’re Awesome

Engineering ceramics are special because they’re stronger than metal and can handle crazy heat. They’re used in big stuff like car engines and tiny things like phone chips. At Eshino Precision, we make these ceramics—like zirconia—to help industries shine. Let’s dive into why they’re the future!

What Are Engineering Ceramics?

The Basics Made Simple

Engineering ceramics are tough, high-tech materials made for hard jobs. Unlike the clay pots your grandma might use, these are super strong and built for things like car engines. They’re made from stuff like alumina and zirconia, not regular dirt!

Superheroes of Materials

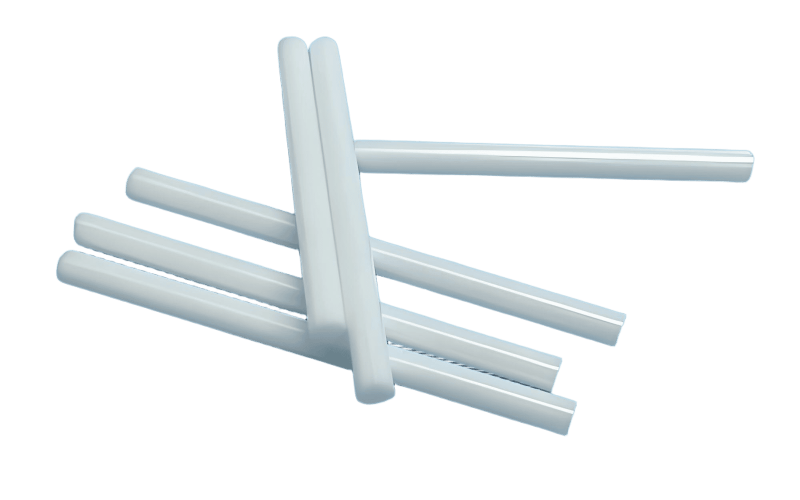

Think of engineering ceramics as the superheroes of materials! They’re tough, heat-resistant, and last a long time. At Eshino Precision, we use them to make parts like zirconia rods. They’re perfect when metal or plastic just can’t cut it!

How They’re Different

Regular ceramics are for cups or tiles, but engineering ceramics are for big challenges. They don’t break easily and can handle heat up to 2680°C—that’s hotter than lava! “These ceramics are game-changers for tough tasks,” says Dr. Emily Chen, a ceramics expert at InnoTech Labs. Learn more at what structural ceramics are!

Types of Engineering Ceramics

Oxide Ceramics: The Tough Ones

Oxide ceramics are a big group of engineering ceramics. Alumina is super hard and great for electronics like computer chips. Then there’s zirconia—it’s strong and safe for medical implants. We love zirconia at Eshino Precision!

Non-Oxide Ceramics: Heat Champs

Non-oxide ceramics are awesome too! Silicon nitride is perfect for car engines because it stays strong in heat. Silicon carbide is tough and used in semiconductors. They’re like the heat-proof heroes of ceramics!

Composite Ceramics: Extra Strong

Composite ceramics mix things up for extra power. They blend ceramics with fibers to make them tougher, like for plane parts. Think of them as a superhero team-up! We use these ideas to make strong products at Eshino Precision.

Why Engineering Ceramics Stand Out

Super Strong Stuff

Engineering ceramics are crazy strong! They can hold up heavy loads without breaking. That’s why they’re great for big machines. Here’s what makes them special:

- High Strength: Holds up tons of weight!

- Thermal Stability: Stays cool in 2680°C heat!

- Durability: Lasts super long without wearing out.

Heat? No Sweat!

These ceramics can take heat like champs! Zirconia can handle 2680°C, and silicon carbide is close behind. They’re perfect for hot places like furnaces or chemical plants. Check out more at heat resistance!

Body-Safe and Light

Here’s more cool stuff about engineering ceramics:

- Biocompatibility: Safe for teeth and bones.

- Lightweight: Makes cars and planes faster.

Some are even harder than diamonds! See why they’re awesome at ceramic properties!

Zirconia Rod - Super Strong!

Silicon Nitride Tube - Heat-Proof!

Where Engineering Ceramics Shine

Cars That Go Zoom

Engineering ceramics are superstars in cars! They make engine parts like pistons that handle heat and last long. They’re also in brakes and sensors to keep cars running smoothly. At Eshino Precision, we help make cars tougher!

Planes Up High

In planes, engineering ceramics are amazing! They’re used in turbine blades that spin super fast in hot engines. These ceramics are light and strong, so planes fly better. “Ceramics make aerospace parts unbeatable,” says Dr. Emily Chen from InnoTech Labs. Check out our aerospace uses!

Tech in Your Pocket

Your phone and computer use engineering ceramics too! Alumina makes tiny parts for chips that don’t let electricity leak. Silicon carbide helps make fast tech stuff. They’re small but mighty, keeping your gadgets going!

Helping Doctors

Engineering ceramics shine in medicine! Zirconia is perfect for dental crowns and hip implants because it’s safe and strong. They don’t wear out fast, so they help people feel better longer. We make these at Eshino Precision!

How Engineering Ceramics Are Made

Picking the Good Stuff

First, engineering ceramics start with special powders like zirconia or alumina. We pick the best ones at Eshino Precision. These powders are super fine, like sugar, to make strong parts!

Shaping the Fun

Next, we shape the powder into cool things! We press it hard, mold it like clay, or squeeze it into tubes. It’s like making toys, but for tough jobs. This step makes sure the ceramics fit just right!

Baking It Strong

Then, we bake the shaped ceramics in a super-hot oven—up to 1700°C! This is called sintering, and it sticks everything together tight. It’s like turning dough into a hard cookie, but way hotter! Check out how they handle heat.

Finishing Touches

Finally, we polish engineering ceramics with special tools. They get smooth and shiny, ready for cutting tools or implants. Eshino Precision makes them perfect for you!

The Booming Market for Engineering Ceramics

Big Money, Big Growth

The market for engineering ceramics is huge! In 2023, it was $6.76 billion. By 2025, it’s jumping to $7.42 billion, and by 2032, it’ll hit $10.3 billion. That’s growing 4.8% every year! People love these ceramics for new tech.

Why It’s Growing

So, why are engineering ceramics booming? Cars, especially electric ones, need light, strong parts. Doctors use them for more implants too. Plus, planes are using them to fly better. It’s all about making things last longer and work great!

What’s Driving It

Places like Asia and the U.S. are building more, so they need ceramics for furnaces. Some say the market is smaller, but most agree it’s billions and growing fast. Eshino Precision is ready to help with that!

Frequently Asked Questions

What Are Engineering Ceramics?

People ask, “What are engineering ceramics?” They’re tough materials for hard jobs, like machine parts. They’re made to be strong and heat-proof, not like regular pottery!

Why Use Them?

“Why use engineering ceramics?” Easy—they’re super strong, last long, and handle heat well. They’re perfect for tough stuff like engines and implants!

Where Are They Used?

“Where do they go?” Everywhere! Cars, planes, phones, and even doctor tools. Engineering ceramics make everything better and stronger!

How Big Is the Market?

“How big is it?” It’s growing to $7.42 billion by 2025! That’s because more people want ceramics for cars and tech. It’s a big deal!

The Future of Engineering Ceramics

3D Printing Magic

Engineering ceramics are getting cooler with 3D printing! Soon, we can make tricky shapes super fast, like parts for planes or implants. It’s like building with Lego, but tougher! This saves time and makes awesome stuff at Eshino Precision.

Tiny and Mighty

The future has tiny engineering ceramics called nanoceramics! They’re smaller but stronger, perfect for phone chips and doctor tools. Imagine a super-strong speck making your gadgets better—that’s where we’re headed!

Green and Powerful

Engineering ceramics will help the planet too! They’re going into fuel cells for clean energy. They handle heat and last long, so they’re great for green power. “The future of ceramics is sustainable,” says Dr. Emily Chen from InnoTech Labs. We’re excited to help at Eshino Precision!

Why Partner with Eshino Precision?

We’ve Got the Best Ceramics

At Eshino Precision, we make top-notch engineering ceramics! Our zirconia ceramics are super strong and perfect for tons of jobs. From rods to tools, we’ve got it all!

Custom Cool Stuff

We don’t just make engineering ceramics—we make them your way! Need a special part for a car or a tooth? We can do it! Our team knows how to shape and bake ceramics just right. Check out custom parts to see how we help!

Ready to Help You

Why pick us? Because we’re experts at making engineering ceramics last long and work great. They save you money by not breaking down fast—see how at maintenance costs. Need tough solutions? Call us today!

More Cool Info

Want to learn more? Here are some great places to look:

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.