Table of Contents

Key Takeaways: Why Custom Ceramic Components Rock

Custom ceramic components are like superheroes for machines! They’re strong, last long, and fit perfectly for tough jobs. Here’s a quick table to show why they’re awesome:

| Benefit | Why It’s Cool |

|---|---|

| Super Strong | Handles heat and pressure like a champ. |

| Long-Lasting | Doesn’t wear out or rust easily. |

| Perfect Fit | Made exactly for your needs. |

| Saves Money | Lasts longer, so you replace less. |

| Custom Shapes | Designed to solve your specific problem. |

This table gives you the top reasons to love custom ceramic components. Next, let’s dive into what they are and why they matter!

Introduction to Custom Ceramic Components

What Are Custom Ceramic Components?

Imagine a super-tough puzzle piece made just for a machine. That’s what custom ceramic components are! Unlike regular ceramics, like your grandma’s teacup, these parts are specially designed for big jobs in places like airplanes, hospitals, or factories. They’re made to be extra strong, fit perfectly, and handle crazy conditions like super-hot temperatures or heavy pressure.

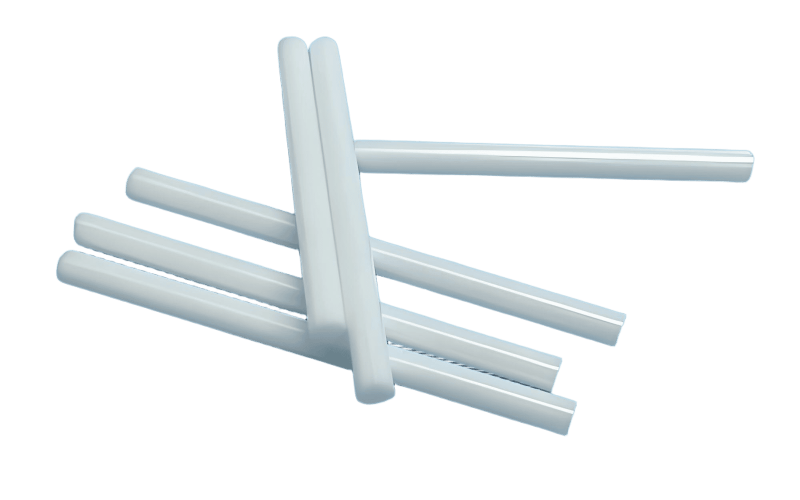

At Eshino Precision, we create these parts to solve tough problems. For example, our ceramic seals keep machines leak-free, and our ceramic rods are tough enough for heavy-duty tasks. These parts are like the unsung heroes of industries!

Why Do They Matter?

Custom ceramic components matter because they make machines work better and last longer. Regular materials like metal might break or wear out, but ceramics can take the heat and keep going. Plus, they’re made to fit exactly what you need, so there’s no waste. Whether it’s a tiny part for a medical tool or a big piece for an airplane, ceramics get the job done.

“Custom ceramic components are game-changers for industries needing precision and durability,” says Dr. Emily Chen, a materials engineer with 15 years of experience. “Their ability to handle extreme conditions makes them essential for modern engineering.”

Want to learn more about what makes ceramics special? Check out our guide on structural ceramics to see why they’re so cool!

Applications Across Industries

Where Are Custom Ceramic Components Used?

Custom ceramic components are used in tons of places because they’re so tough and reliable. Think of them as the secret sauce in machines that need to work perfectly. Here’s where you’ll find them:

- Airplanes and Spacecraft: Parts like zirconia ceramic rods handle super-hot temperatures in engines.

- Hospitals: Ceramics are in medical tools and implants because they’re safe for the body.

- Electronics: Tiny parts in phones and computers, like ceramic substrates, keep things running smoothly.

- Cars: Ceramics in sensors and spark plugs make cars more efficient. Learn more in our automotive ceramics guide.

- Energy: Parts in solar panels and batteries last longer with ceramics.

- Factories: Ceramic valves and pumps work in tough conditions without breaking.

Why Industries Love Them

These industries pick ceramics because they’re super strong and don’t wear out easily. For example, in factories, ceramics can handle harsh chemicals without rusting. In hospitals, they’re safe and clean for patients. No matter the job, custom ceramic components make things better and last longer.

Curious about ceramics in specific fields? Explore how they shine in medical applications or oil and gas!

Ceramic Seal for Leak-Free Machines

Zirconia Rod for High-Heat Jobs

Benefits of Custom Ceramic Components

Why Are They So Great?

Custom ceramic components are like the best players on a team. They bring awesome benefits that make machines work better. Let’s break down why they’re so special:

- Super Strong: Ceramics like silicon nitride can handle heavy loads and hot temperatures without breaking.

- Last Forever: They resist wear and rust, so parts like ceramic bushings stay good for years.

- Perfect Fit: Made to exact sizes, they fit machines like a glove.

- Save Money: Because they last so long, you don’t need to replace them often. Check out how ceramics cut maintenance costs.

- Custom Designs: Need a weird shape? Ceramics can be made just for you.

How They Help Your Work

These benefits make your machines run smoother and last longer. For example, in a factory, a ceramic part can keep working in harsh conditions without needing repairs. In a car, ceramics make engines more efficient, saving gas. Plus, because they’re custom, you get exactly what you need, no compromises.

“The precision and longevity of custom ceramic components are unmatched,” notes John Rivera, a manufacturing consultant. “They’re a smart investment for any industry looking to boost performance.”

Want to dive deeper? See the top benefits of zirconia ceramics for more details!

Materials for Custom Ceramic Components

What Are These Parts Made Of?

Custom ceramic components are made from special materials that are super tough. Each material is like a different superhero with its own powers. For example, some are great at handling heat, while others are super strong. At Eshino Precision, we use these materials to make parts that work perfectly for your needs. Here’s a table to show the most common ones:

| Material | Super Powers | Where It’s Used |

|---|---|---|

| Alumina | Strong, blocks electricity | Medical tools, electronics |

| Zirconia | Tough, resists scratches | Cutting tools, bearings |

| Silicon Carbide | Handles heat, super durable | Airplane parts, factory tools |

| Silicon Nitride | Strong, resists sudden heat changes | Car engines, turbines |

Alumina is the most popular material, making up over 36% of the market because it’s so versatile (Grand View Research). Want to know more? Check out our zirconia vs. alumina guide.

Why Material Choice Matters

Picking the right material is like choosing the best tool for a job. For example, if you need a part for a hot airplane engine, silicon carbide rods are great because they stay strong in heat. For medical tools, alumina is safe and clean. Our team at Eshino Precision helps you pick the perfect material for your project. Learn more about choosing materials in our material guide.

Manufacturing Processes

How Are Custom Ceramic Components Made?

Making custom ceramic components is like baking a super-strong cake! It takes a few steps to turn raw materials into tough parts. Here’s how it works:

- Mix the Ingredients: We start with ceramic powders, like zirconia, and mix them with special helpers to make them stick together.

- Shape It: The mix is pressed or molded into the shape you need, like a ceramic tube.

- Bake It: The shaped part is heated in a super-hot oven to make it strong. This is called sintering.

- Polish It: We use tools to make the part super smooth and exact, like for ceramic pins.

- Add Extras: Sometimes, we add coatings to make the part even better.

New tricks, like 3D printing, let us make complex shapes faster. Curious? Read about ceramic CNC machining for more details.

Why This Process Is Cool

This process makes sure every part is just right. For example, precise polishing means a ceramic seal fits perfectly with no leaks. Plus, the baking step makes parts super tough, so they last a long time. At Eshino Precision, we’re experts at getting every step perfect.

Market Trends and Statistics

How Big Is the Ceramics World?

The world of custom ceramic components is growing fast because everyone wants tough, reliable parts. Here’s a table with some cool numbers:

| Year | Market Size (USD Billion) | Growth Rate |

|---|---|---|

| 2024 | 12.2 | – |

| 2029 | 17.5 | 7.4% |

This data comes from MarketsandMarkets. It shows the market for ceramics is getting bigger every year!

What’s Driving the Growth?

Lots of industries are using more ceramics. For example, electronics need parts like ceramic substrates for phones and computers. Hospitals are using more ceramics for tools and implants. The Asia Pacific region, especially, loves ceramics, making up 42% of the market in 2024 (IMARC Group). This growth means now’s a great time to use ceramics in your projects. Learn more about industry trends in our ceramics impact guide.

Choosing the Right Manufacturer

What to Look for in a Manufacturer

Picking the right company to make your custom ceramic components is super important. Here’s what to check:

- Experience: They should know your industry, like oil and gas.

- Materials: They need lots of options, like alumina or silicon nitride.

- Skills: They should use cool tools, like CNC machining.

- Quality: They must test parts to make sure they’re perfect.

- Speed and Price: They should deliver on time and not cost too much.

Why Eshino Precision Is Awesome

At Eshino Precision, we check all these boxes. We’ve made parts like ceramic nozzles for tough jobs and always focus on quality. Talk to us early to get the best parts for your project!

Real-World Case Studies

Ceramics in Action

Custom ceramic components do amazing things! Here are some examples:

- Airplanes: Zirconia parts in engines handle crazy heat, making planes fly better.

- Hospitals: Alumina implants help patients heal because they’re safe.

- Electronics: Silicon nitride tubes make computers run faster with less energy.

Why These Stories Matter

These examples show how ceramics solve real problems. At Eshino Precision, we can make parts like these for your needs. Want to see more? Check out our silicon nitride in engines guide.

People Also Ask: Common Questions Answered

Your Questions, Answered!

People have lots of questions about custom ceramic components. Here are the top ones with simple answers:

- What are the benefits? They’re strong, last long, fit perfectly, save money, and can be custom-shaped.

- How are they made? Through mixing, shaping, baking, polishing, and adding extras. See our machining guide.

- Which industries use them? Airplanes, hospitals, electronics, cars, energy, and factories.

- What materials are used? Alumina, zirconia, silicon carbide, and silicon nitride. Learn more in our materials page.

- How do I tell a manufacturer what I need? Share drawings, sizes, and what the part does. We’ll help at Eshino Precision.

Conclusion

Why Custom Ceramic Components Are the Future

Custom ceramic components are super-strong, long-lasting parts that make machines better in every industry. From airplanes to hospitals, they solve tough problems with their perfect fit and durability. At Eshino Precision, we’re experts at making these parts just for you, using materials like zirconia and silicon carbide. With the ceramics market growing fast, now’s the perfect time to try them out!

External Resources

- Technical Ceramics Market Forecast – Learn about market growth trends.

- Grand View Research on Ceramics – Dive into material popularity stats.

- IMARC Group Market Insights – Explore regional market data.

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.