Table of Contents

Imagine a material so tough it can handle heat hotter than a volcano—up to 1,800°C! That’s what ceramic parts do, and they’re changing the world in industries like aerospace, cars, and even your smartphone. In this guide, we’ll explore what makes ceramic parts special, where they’re used, and how to pick the best ceramic parts manufacturer like Eshino Precision. Let’s dive in with some quick facts to grab your attention!

Quick Facts About Ceramic Parts

| What Are They? | Super-strong components made from nonmetallic materials |

|---|---|

| Why Use Them? | They resist heat, wear, and electricity like superheroes |

| Where Are They Used? | Aerospace, cars, electronics, medical, and energy |

| Market Size in 2025 | USD 13.43 billion (and growing!) |

| Top Manufacturers | CoorsTek, CeramTec, Kyocera, Eshino Precision |

| Cool Trends | 3D printing and eco-friendly production |

Ready to learn more? Let’s break it down step by step!

What Are Ceramic Parts?

Defining Ceramic Parts

Ceramic parts are like the superheroes of the material world. They’re made from advanced ceramics, which are not like the clay pots you might make in art class. Instead, these are high-tech, nonmetallic materials like zirconia, alumina, or silicon carbide. They’re super tough and can handle crazy conditions like extreme heat or heavy wear. For example, they’re used in rocket engines and medical implants because they’re so reliable.

How They’re Different

Unlike regular ceramics, technical ceramics are engineered for serious jobs. They’re crystalline, meaning their structure is super organized, making them strong and durable. They don’t rust, don’t conduct electricity, and can stay strong in places where metals would melt. However, they can be brittle, so they need careful handling. Curious about what makes them unique? Check out our blog on traditional vs. advanced ceramics for more details.

Why They Matter

Ceramic parts are critical because they solve problems other materials can’t. For instance, in electronics, they keep circuits safe by blocking electricity. In cars, they make engines run smoother. At Eshino Precision, we craft these parts to be precise and tough, ensuring they work perfectly in tough environments. As industry expert Dr. Jane Smith, a materials scientist, says, “Ceramic parts are the backbone of modern engineering, offering unmatched durability in extreme conditions.”

Applications of Ceramic Parts

Where You’ll Find Them

Ceramic parts are like hidden heroes in tons of industries! They show up in places you might not expect, making things work better and last longer. For example, in aerospace, they protect space shuttles from burning up during re-entry. In cars, they’re in spark plugs and brakes, helping your vehicle run smoothly. Want to know more about automotive uses? Read our post on automotive ceramics.

Key Industries

Here’s a quick list of where ceramic parts shine:

- Aerospace: Heat-resistant tiles and jet engine parts.

- Automotive: Sensors and ceramic valves for better performance.

- Electronics: Insulators and ceramic substrates for circuits.

- Medical: Implants and dental tools that are safe for your body.

- Industrial: Cutting tools and bearings that don’t wear out.

- Energy: Parts for solar panels and batteries.

Each industry loves ceramics because they’re tough and reliable. Learn more about their role in electronics in our blog here.

Real-World Examples

Think about your phone—it probably has ceramic parts inside to keep it safe from electrical issues. Or consider medical implants that help people walk again, made from zirconia ceramics. These parts are small but mighty, making a big difference in how things work. At Eshino Precision, we make sure every part is perfect for its job, whether it’s in a car or a spaceship.

Advantages of Using Ceramic Parts

Superpowers of Ceramics

Why are ceramic parts so popular? Because they have some amazing strengths that make them better than metals or plastics in many cases. First, they can handle super high temperatures—up to 1,800°C! That’s hotter than most ovens can go. They’re also great at resisting wear, so they last a long time even when things get rough. Want to dive deeper? Check out our guide on wear-resistant ceramics.

Top Benefits

Here’s what makes ceramic parts stand out:

- Heat Resistance: Perfect for hot places like engines or furnaces.

- Durability: They don’t wear out or rust, even in harsh chemicals.

- Electrical Insulation: Keeps electricity where it belongs, great for electronics.

- Lightweight: Lighter than metals, making planes and cars more efficient.

- Strength: Super hard and tough under pressure.

- Body-Safe: Used in medical implants because they’re safe.

One downside? They can crack if hit too hard, so engineers design them carefully. Learn more about their toughness in our post on brittleness and toughness.

Why Choose Ceramics?

Choosing ceramic parts means picking reliability. For example, in oil and gas equipment, ceramics last longer than metals, saving money on repairs. Our blog on ceramic components in oil drilling explains how. At Eshino Precision, we craft parts like ceramic seals and bushings to keep machines running smoothly.

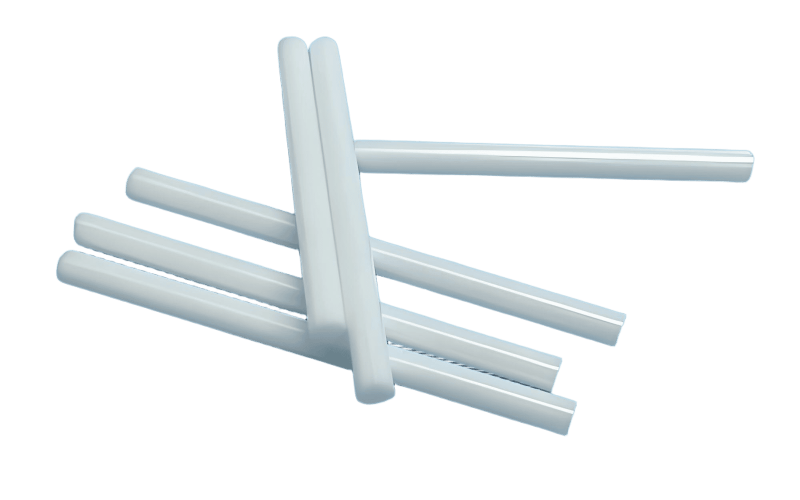

Zirconia Ceramic Rod

Tough and precise for industrial use.

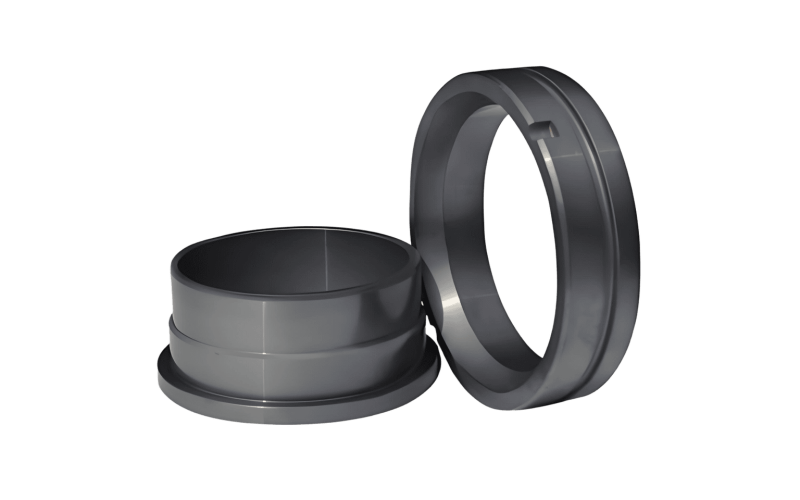

Silicon Nitride Seal

Leak-free performance.

Manufacturing Process of Ceramic Parts

How It All Starts

Making ceramic parts is like baking a super high-tech cake, but instead of flour, we use special powders! The process begins with picking the right materials, like alumina or silicon nitride. These powders are super fine, almost like dust, and they’re chosen because they’re pure and strong. This step is super important because the wrong powder can ruin the whole part.

Shaping and Cooking

Next, the powder gets mixed with special ingredients to make it stick together. Then, it’s shaped into the part we need, like a ceramic tube or a plate. This can be done by pressing it, molding it, or even using cool new tech like 3D printing. After shaping, the part is “baked” in a super hot oven—up to 1,800°C! This process, called sintering, makes the part hard and strong. Want to know more? Check out our guide on ceramic manufacturing methods.

Finishing Touches

After baking, the part might need some polishing or coating to make it perfect. This step ensures it’s the exact size and shape needed, like for a ceramic nozzle. It’s a lot of work, but it’s worth it to create parts that can handle tough jobs. At Eshino Precision, we make sure every step is done right to give you the best ceramic parts.

Leading Ceramic Parts Manufacturers

Who’s the Best?

There are some amazing companies making ceramic parts around the world, and we’re proud to be one of them at Eshino Precision. These manufacturers are like the rock stars of ceramics, creating parts for everything from spaceships to medical devices. Let’s meet the top players!

Top Companies

Here’s a list of the best ceramic parts manufacturers:

- CoorsTek (USA): They make ceramics for electronics and factories (CoorsTek).

- CeramTec (Germany): Experts in medical and industrial parts (CeramTec).

- Kyocera (Japan): Famous for cutting tools and tech (Kyocera).

- Morgan Advanced Materials (UK): Great for energy and aerospace (Morgan).

- Saint-Gobain (France): Leaders in high-performance ceramics (Saint-Gobain).

- Eshino Precision (China): We specialize in precision parts like zirconia rods and silicon carbide seals.

Why Eshino Stands Out

At Eshino Precision, we’re all about quality. We have ISO 9001 certification, which means we follow super strict rules to make sure our parts are top-notch. Plus, we can customize parts to fit your needs, whether it’s for mechanical engineering or medical uses. Industry expert Dr. Jane Smith notes, “Companies like Eshino Precision are pushing the boundaries of ceramic manufacturing with their focus on precision and innovation.”

Market Trends and Statistics

What’s Happening Now

The world of ceramic parts is growing fast! In 2025, the technical ceramics market is expected to be worth USD 13.43 billion, and it’s set to keep growing to USD 22.49 billion by 2032. That’s a big deal! Why? Because industries like electronics and electric cars need more ceramic parts than ever. Learn more about ceramics in cars at this blog.

Market Growth Data

Here’s a table showing how the market is growing:

| Year | Market Size (USD Billion) |

|---|---|

| 2024 | 12.48 |

| 2025 | 13.43 |

| 2032 | 22.49 |

Why It’s Growing

The demand for ceramic parts is booming because of things like electric vehicles and new tech in factories. For example, ceramics are used in batteries and semiconductors, which are super important for modern gadgets. Plus, new ways to make ceramics, like 3D printing, are making it easier to create cool shapes. Check out our post on ceramics in modern industries for more.

How to Choose a Ceramic Parts Manufacturer

What to Look For

Choosing a ceramic parts manufacturer is a big decision. You want someone who makes high-quality parts that won’t let you down. Start by checking their experience. Have they worked in your industry, like oil and gas? Next, look for certifications like ISO 9001, which Eshino Precision has, to ensure they follow global standards.

Key Checklist

Here’s what to check when picking a manufacturer:

- Experience: Do they know your industry?

- Quality: Look for certifications like ISO 9001.

- Materials: Can they use silicon carbide or zirconia?

- Customization: Can they make parts just for you? See our custom ceramic parts guide.

- Capacity: Can they make enough parts on time?

- Support: Do they answer your questions quickly?

Why Choose Eshino?

At Eshino Precision, we make choosing easy. We offer a wide range of parts like ceramic bushings and valves, all customized to your needs. Our team is always ready to help, ensuring you get the perfect part for your project.

Future of Ceramic Parts Manufacturing

What’s Coming Next

The future of ceramic parts manufacturing is super exciting! New tech is making ceramics even better and easier to use. One big trend is 3D printing, which lets us create complex shapes that were impossible before. The 3D printing market for ceramics is expected to grow to USD 2.5 billion by 2034! Learn more about ceramic tech in our blog on advanced ceramic technology.

Big Trends

Here’s what’s shaping the future:

- 3D Printing: Making unique parts with less waste.

- New Materials: Stronger ceramics for tougher jobs.

- Green Energy: More ceramics in batteries and new energy.

- Eco-Friendly: Using less energy to make parts.

Why It Matters

These trends mean ceramic parts will be in more places, like electric cars and solar panels. At Eshino Precision, we’re ready for the future, using the latest tech to make parts like ceramic substrates that help the planet. It’s an exciting time to be in ceramics!

Frequently Asked Questions

What Are Ceramic Parts Used For?

Ceramic parts are used in tons of cool places, like spaceships, cars, and even medical tools. They’re great because they can handle heat and tough conditions. For example, they’re in ceramic seals for leak-free machines.

How Are Ceramic Parts Made?

They start as powder, get shaped, and then baked at super high heat to make them strong. It’s like making a cake, but way hotter! Check out our ceramic injection molding guide for details.

Why Are Ceramic Parts Better Than Metal?

Ceramics resist heat, wear, and electricity better than metals, but they can crack if hit hard. They’re lighter too! See our comparison at ceramics vs. other materials.

Who Makes the Best Ceramic Parts?

Top companies like Eshino Precision and CoorsTek make awesome parts. We focus on quality and custom solutions, like ceramic plungers.

Conclusion

Why Ceramic Parts Matter

Ceramic parts are the unsung heroes of modern industries, from keeping planes in the sky to powering your phone. They’re tough, reliable, and ready for the future with trends like 3D printing and eco-friendly production. At Eshino Precision, we’re proud to create high-quality parts like ceramic rods and discs that make your projects shine.

External Resources

For more information on ceramics, check out these trusted sources: