Table of Contents

Key Takeaway: Why Ceramic CNC Machining Matters

Ceramic CNC machining creates precise, durable parts for industries like aerospace and medical. Here’s a quick look at its value:

| Feature | Benefit |

|---|---|

| High Precision | Tight tolerances for complex designs |

| Durability | Resists wear, heat, and corrosion |

| Scalability | Ideal for prototyping or mass production |

| Market Growth | $113.29B in 2024, projected to $250.30B by 2032 |

Introduction: What is Ceramic CNC Machining?

Understanding the Basics

Ceramic CNC machining is a cool way to shape super tough materials like ceramics using computers to control tools. Imagine a robot artist carefully carving out parts from hard stuff like zirconia or alumina. These ceramics are brittle, kind of like glass, but super strong and can handle crazy heat. This process makes parts for things like airplane engines or medical implants with amazing precision. At Eshino Precision, we use ceramic CNC machining to create top-notch components for all sorts of industries.

Why It’s a Big Deal

Unlike old-school methods, ceramic CNC machining uses computers to make sure every cut is perfect. This means we can make complicated shapes that fit exactly where they’re needed. For example, parts for medical devices or aerospace equipment need to be spot-on, and CNC makes that happen. Plus, the advanced ceramics market is growing fast—it’s worth $113.29 billion in 2024 and could hit $250.30 billion by 2032, according to Fortune Business Insights. That shows how much people trust this technology!

Eshino Precision’s Role

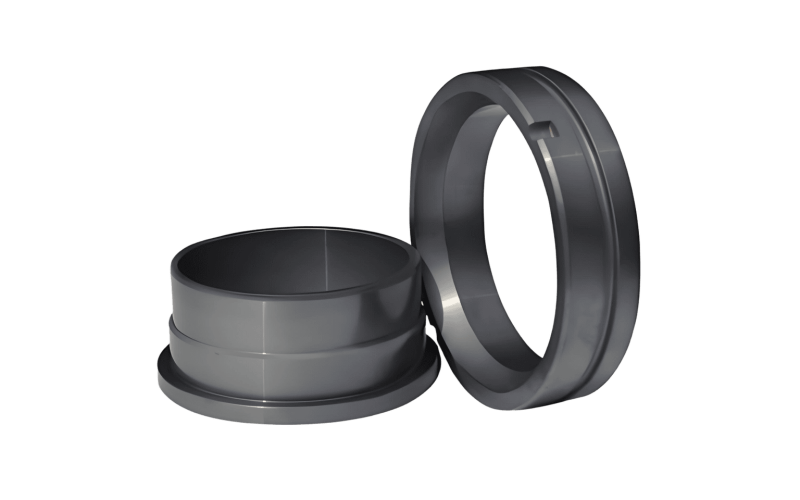

At Eshino Precision, we’re experts in structural ceramics. We use ceramic CNC machining to make parts that last longer and work better, whether it’s a ceramic seal or a nozzle. Our process ensures every piece meets strict standards, making us a go-to for industries needing reliable solutions.

“Ceramic CNC machining is a game-changer for precision manufacturing. It allows us to push the limits of what ceramics can do,” says Dr. Jane Miller, a materials engineer at Advanced Ceramics Solutions.

Why Ceramics Matter: Properties and Benefits

Super Powers of Ceramics

Ceramics are like superheroes in the material world. They’re super hard, can handle scorching heat, and don’t wear out easily. These traits make them perfect for tough jobs, like in cars or electronics. For example, ceramics like silicon nitride are so tough they’re used in engine parts that face extreme conditions. Learn more about their high strength and wear resistance on our site.

Benefits of CNC Machining Ceramics

When we use ceramic CNC machining, these awesome properties shine even brighter. The computer-controlled tools let us make parts with exact shapes, which is super important for things like ceramic valves or bushings. Plus, CNC machining is fast and can make one part or thousands, saving time and money. It’s like having a magic wand to turn tough ceramics into perfect components!

Why Eshino Precision Loves Ceramics

At Eshino Precision, we know ceramics are special. That’s why we use ceramic CNC machining to create parts that last longer and work better than those made from other materials. Whether it’s a ceramic plate for electronics or a rod for machinery, our process ensures top quality. Check out how we use ceramics to reduce maintenance costs for our clients!

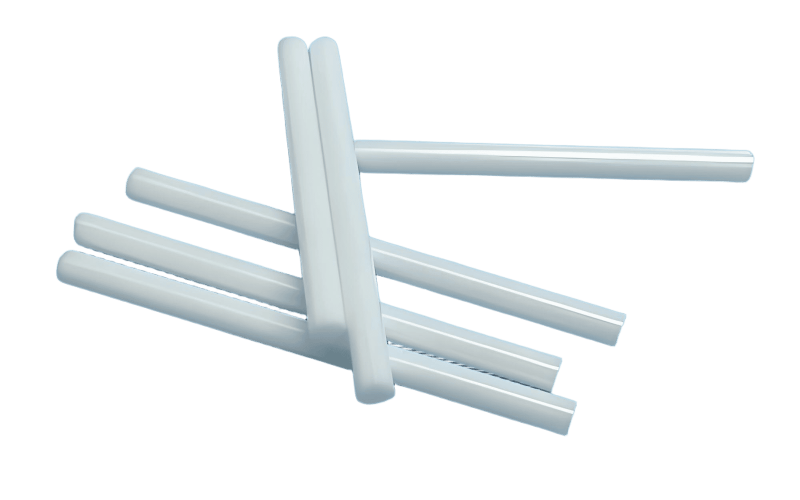

Zirconia Rod for Precision Applications

Silicon Nitride Tube for High Heat

Types of Ceramics for CNC Machining

Popular Ceramics We Use

Not all ceramics are the same! Each type has its own superpowers, and we pick the right one for the job. Here are the main ones we use in ceramic CNC machining:

- Alumina (Al2O3): Super hard and great at keeping electricity out. Perfect for insulators and medical seals.

- Zirconia (ZrO2): Strong and safe for the body, used in dental implants and tools.

- Silicon Carbide (SiC): Loves heat and resists chemicals, great for semiconductor parts.

- Silicon Nitride (Si3N4): Tough and handles sudden heat changes, ideal for turbine blades.

Comparing Ceramic Properties

Here’s a quick table to show what each ceramic is best at:

| Ceramic | Key Property | Common Use |

|---|---|---|

| Alumina | High hardness | Insulators |

| Zirconia | Biocompatibility | Dental implants |

| Silicon Carbide | Heat resistance | Semiconductor parts |

| Silicon Nitride | Thermal shock resistance | Turbine blades |

Fun fact: Alumina makes up over 40% of the advanced ceramics market because it’s so versatile, says Grand View Research.

Choosing the Right Ceramic

At Eshino Precision, we help you pick the best ceramic for your project. For example, if you need a part that won’t break under heat, we might suggest silicon carbide rods. If it’s for a medical device, zirconia tubes could be the way to go. Check out our guide on choosing the right ceramic material for more tips!

How Ceramic CNC Machining Works

The Magic of CNC Technology

Ceramic CNC machining is like a super-smart robot sculptor. It uses computers to guide tools that cut and shape tough ceramics like zirconia or silicon carbide. The computer tells the machine exactly where to cut, so every piece comes out perfect. This is way better than doing it by hand because it’s faster and super precise. At Eshino Precision, we use this tech to make parts like ceramic nozzles that fit just right in machines.

Main Machining Processes

There are a few cool ways we shape ceramics with CNC machines:

- Milling: This is like shaving off bits to make flat or fancy surfaces, perfect for ceramic plates.

- Drilling: Uses special diamond-tipped drills to make holes, great for bushings.

- Grinding: Smooths out surfaces to make them super shiny, often used for ceramic seals.

- Turning: Spins the ceramic like a potter’s wheel to shape round parts, like rods.

Fun fact: Milling is used in over 60% of ceramic CNC jobs because it’s so versatile, according to Kadco Ceramics.

Tools That Make It Happen

Ceramics are super hard, so we need tough tools to cut them. We use diamond or cubic boron nitride (CBN) tools because they’re like the superheroes of cutting. These tools can handle the hardness and keep the ceramic from cracking. Plus, we use special liquids to keep everything cool, so the parts don’t get too hot. This helps us make awesome components like ceramic valves for chemical plants.

Applications Across Industries

Where Ceramic Parts Shine

Ceramic CNC machining makes parts for all kinds of cool industries. Because ceramics are so strong and can handle heat, they’re perfect for tough jobs. At Eshino Precision, we make parts for machines, electronics, and more. Here’s where our parts go:

- Aerospace: Think turbine blades that make planes fly faster.

- Medical: Dental implants that are safe for your body.

- Electronics: Insulators that keep gadgets working in hot conditions.

Real-World Impact

Let’s talk numbers: The aerospace ceramics market was worth $0.8 billion in 2022 and is expected to hit $1.2 billion by 2030, growing at 4.8% per year, says DataM Intelligence. That’s because parts like silicon nitride tubes make planes lighter and save fuel. In medical fields, zirconia ceramics are used in implants that last for years, helping people smile confidently.

Eshino Precision’s Solutions

We’re proud to make parts that help industries thrive. For example, our ceramic discs are used in semiconductor equipment, and our flanges keep oil and gas systems running smoothly. Want to know more? Check out how ceramics are changing industries!

Silicon Carbide Nozzle for Tough Jobs

Zirconia Valve for Chemical Plants

Advantages of Ceramic CNC Machining

Why It’s Awesome

Ceramic CNC machining is like having a superpower for making parts. It’s super precise, so parts fit perfectly, whether it’s a ceramic pin or a guide. The parts are also crazy durable—they don’t wear out, rust, or melt in hot places. This makes them great for energy systems or car engines.

Time and Money Savers

Here’s a cool stat: CNC machining can cut production time by up to 50% compared to old methods, according to RapidDirect. That means you get your parts faster! It’s also great for making just one part or tons of them, so it works for small projects or big factories. Plus, it saves money by reducing mistakes, as explained in our blog on reducing maintenance costs.

Eshino Precision’s Edge

At Eshino Precision, we use ceramic CNC machining to make sure every part is top-notch. Our machines can handle tricky designs, like threaded parts, that other methods can’t. We also make sure every piece is the same, so you can trust our ceramic gaskets to work every time. Want to learn more? See how we use ceramics in high-tech manufacturing.

“The precision of CNC machining unlocks ceramics’ full potential, delivering parts that outperform traditional materials,” says Mark Thompson, a manufacturing expert at Precision Tech Innovations.

Challenges and How They’re Solved

Why Ceramics Are Tricky

Ceramic CNC machining sounds awesome, but ceramics can be tough to work with. They’re super hard, like a diamond, but also brittle, like a cookie that cracks if you drop it. This means they can chip or break during machining. Plus, cutting them makes a lot of heat, which isn’t great for the tools or the ceramic. At Eshino Precision, we’ve got tricks to handle these challenges and make perfect parts like ceramic rods or seals.

Smart Solutions

To solve these problems, we use special tools and techniques. For example, we use diamond or cubic boron nitride (CBN) tools because they’re super strong and can cut through tough ceramics like silicon nitride. We also cut slowly to avoid breaking the ceramic and use cool liquids to keep everything from getting too hot. Cool fact: Diamond tools are 5-10 times better than regular tools for ceramics, says 3ERP. We also use computer programs to plan every cut perfectly, so parts like ceramic nozzles come out just right.

Eshino Precision’s Expertise

At Eshino Precision, we’re pros at tackling ceramic challenges. Our machines are built to handle the toughest materials, and our team knows how to keep parts safe from cracks. This means we can make reliable components for oil and gas or medical devices. Want to know more about how ceramics hold up? Check out our blog on brittleness and toughness!

Design Tips for Ceramic Parts

Picking the Right Ceramic

Designing parts for ceramic CNC machining is like choosing the best superhero for a mission. First, you need the right ceramic. For example, if you need a part that’s super strong for aerospace, silicon nitride is awesome. If it’s for a medical implant, zirconia is a safe bet. Our guide on choosing technical ceramics can help you decide!

Getting the Details Right

When designing, you’ve got to think about how precise the part needs to be. Ceramics can be machined to super tight fits, but they’re brittle, so we plan carefully to avoid stress. Also, if the part needs to be super smooth, like a ceramic disc, we might polish it after machining. Good design can cut machining time by 30%, according to Runsom Precision. This saves money and makes parts last longer!

Handling Heat and Wear

If your part will face crazy heat, like in a solar panel system, we design it to spread heat evenly. We also think about wear, especially for parts like ceramic bushings. By choosing ceramics with high wear resistance, we make sure your parts stay strong. At Eshino Precision, we work with you to design parts that fit perfectly and perform great.

Silicon Nitride Seal for Durability

Zirconia Pin for Precision Fit

Real-World Success Stories

Aerospace Wins

Ceramic CNC machining makes some seriously cool stuff! For example, we’ve made silicon nitride turbine blades for airplanes. These blades are 30% lighter than metal ones, which helps planes use less fuel, according to Morgan Technical Ceramics. This is a big deal for aerospace companies looking to save money and help the planet!

Medical Marvels

In the medical world, our zirconia dental implants are a hit. They’re super safe for the body and last for years—98% of them work great even after a decade! This helps people smile confidently. We also make ceramic cutting tools for surgeries, which are precise and durable. Learn more about ceramics in medical applications on our site.

Electronics Excellence

For electronics, we craft alumina substrates that keep gadgets working in hot or tough conditions. These parts are key for semiconductor equipment and sensors. At Eshino Precision, our ceramic CNC machining ensures every part is reliable, helping companies make better tech. See how ceramics are transforming electronics!

“Ceramics machined with CNC precision are revolutionizing industries, from aerospace to healthcare,” says Dr. Sarah Lee, a ceramics specialist at TechCeram Innovations.

Future Trends in Ceramic CNC Machining

New and Improved Ceramics

The world of ceramic CNC machining is getting even cooler! Scientists are creating new ceramics that are stronger and can do more, like zirconia with extra toughness. These new materials will make parts like ceramic rollers even better for tough jobs in cars or solar panels. At Eshino Precision, we’re excited to use these new ceramics to make awesome components!

Smart Machines and Robots

Another big trend is using super-smart machines. Imagine robots and computers working together to make ceramic parts faster and with fewer mistakes. This is called automation, and it’s making ceramic CNC machining more precise. For example, AI can help us make ceramic welding rollers with perfect shapes every time. Plus, these smart machines can work non-stop, which is great for big projects in semiconductor manufacturing.

Going Green

People care about the planet, and so do we! New trends in ceramic CNC machining include eco-friendly ways to make parts. For instance, we’re finding ways to recycle ceramic scraps from making ceramic plungers. Also, new methods use less energy, which is better for the environment. The advanced ceramics market is expected to grow at 10.1% per year until 2032, says Fortune Business Insights, and green tech is a big part of that!

Market Insights

How Big Is the Market?

Ceramic CNC machining is part of a huge industry. The advanced ceramics market was worth $113.29 billion in 2024 and could reach $250.30 billion by 2032, growing at 10.1% per year. That’s a lot of ceramic parts! The CNC machine market is also growing, hitting $101.22 billion in 2025 and expected to reach $195.59 billion by 2032, according to Fortune Business Insights. This shows how much people need precise parts like ceramic guides.

Industry Breakdown

Here’s a quick look at the numbers:

| Market Segment | 2024 Size | 2032 Projection | CAGR |

|---|---|---|---|

| Advanced Ceramics | $113.29B | $250.30B | 10.1% |

| CNC Machine Market | $101.22B | $195.59B | 9.9% |

This growth means more demand for parts like ceramic flanges in chemical plants.

Eshino Precision’s Place

At Eshino Precision, we’re ready to meet this growing demand. Our ceramic CNC machining services create parts for all sorts of industries, from electronics to oil and gas. Whether it’s a ceramic pin or a substrate, we make sure every piece is top quality. Check out how ceramics are used across industries!

FAQs: Your Questions Answered

What Is Ceramic CNC Machining?

What Are the Benefits?

It’s precise, makes durable parts, and can create tricky shapes fast. Plus, it works for one part or thousands, saving time and money. Learn more about ceramic advantages.

Which Ceramics Are Used?

We use zirconia, silicon carbide, silicon nitride, and more, each picked for its special powers like heat resistance.

Which Industries Use It?

Aerospace, medical, electronics, and more love ceramic parts for their strength and precision.

Conclusion: Why Choose Eshino Precision?

Your Partner in Precision

Ceramic CNC machining is a big deal because it makes super strong, precise parts for industries like automotive and medical. At Eshino Precision, we’re experts at turning tough ceramics into perfect components, whether it’s a ceramic bushing or a cutting tool. Our process ensures top quality, saving you time and money.

External Resources

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.