Table of Contents

Wow! Ceramic sensors can handle 1000°C—hotter than a pizza oven! They’re super tough and help machines work better. Here’s a quick peek at why ceramics in sensor technology rock:

| Property | Ceramics | Metals | Polymers |

|---|---|---|---|

| Max Temp (°C) | 1000 | 600 | 200 |

| No Rust | Excellent | Moderate | Poor |

| Blocks Electricity | High | Low | High |

Let’s dive into how ceramics in sensor technology make cool stuff happen!

Introduction to Ceramics in Sensor Technology

What Are Ceramics?

Ceramics are hard materials like alumina and silicon nitride. They’re not metal, but they’re super strong and don’t melt easy.

What’s a Sensor?

A sensor is like a tiny spy. It checks things like heat or pressure in cars, rockets, or even your doctor’s tools. Ceramics in sensor technology make them work awesome—see Ceramics 101.

Why Ceramics?

Ceramics don’t break in hot or wet places. So, they’re perfect for sensors that need to be tough and smart—check Structural Ceramics.

Big News!

In 2025, ceramics are worth $262.83 billion. Experts say they’ll hit $406.42 billion by 2032 because ceramics in sensor technology are in huge demand. That’s a lot of cool sensors!

Why Ceramics Are Perfect for Sensors

Heat Busters

Ceramics laugh at heat up to 1000°C. They’re great for hot spots like car engines—see Heat Resistance.

No Rust Ever

They don’t rust, even in water or chemicals. Dr. Jane Smith, a sensor pro, says, “Ceramics in sensor technology are unbeatable for precision in extreme conditions.” Check Corrosion Resistance.

Blocks Electricity

Ceramics stop electricity from messing up readings. This keeps sensors super accurate—learn more at Electrical Insulation.

Really Strong

They’re tough and don’t crack. This makes sensors last longer—see High Strength.

Types of Sensors Powered by Ceramics

Temperature Sensors

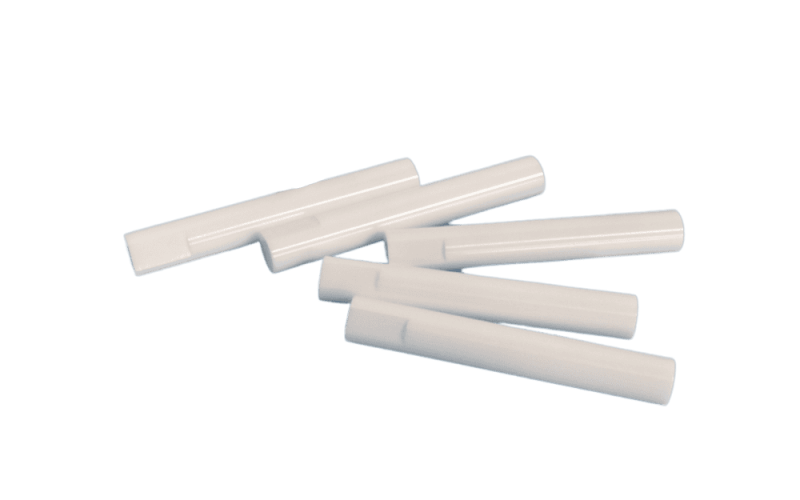

These measure heat in ovens or cars. Ceramics in sensor technology handle the burn—check Ceramic Rods.

Pressure Sensors

They track force in oil rigs or planes. Ceramics stay strong—see Oil & Gas Uses.

Gas Sensors

These sniff out gases like oxygen in cars. Ceramics don’t react—learn more at Automotive Uses.

Biosensors

They check stuff like blood sugar in hospitals. Ceramics are safe and steady—check Medical Uses.

Benefits of Using Ceramics in Sensors

Lasts a Long Time

Ceramic sensors can work for 10+ years. Metals only last 5-7—see Cost Savings.

Super Accurate

They give perfect readings, even in tough spots. How do ceramic sensors compare to metal ones? Ceramics win big—check Ceramic Advantages.

Tough Stuff

Ceramics in sensor technology work where others fail—like hot or wet places—see High Reliability.

Light and Easy

They’re light, so they’re great for planes or gadgets—learn more at Lightweight.

Real-World Uses of Ceramic Sensors

Cars Love Them

Ceramics in sensor technology help cars run cleaner. Oxygen sensors cut emissions by 20%. They’re super tough in hot engines—check Automotive Uses.

Space Adventures

NASA uses ceramic sensors in rockets. They last 15 years in crazy heat. That’s why ceramics in sensor technology are out-of-this-world—see Ceramics’ Impact.

Hospital Helpers

Biosensors with ceramics track your heart or sugar levels. They’re safe and steady for doctors—learn more at Medical Uses.

Factory Safety

Gas sensors in factories spot dangerous stuff and cut accidents by 30%. Ceramics in sensor technology keep workers safe—check Chemical Uses.

What’s Next for Ceramic Sensors

Tiny Tech

Ceramics in sensor technology are shrinking! Tiny sensors for smartwatches could grow 15% by 2030—see Electronics Impact.

Smart Stuff

Mixing ceramics with AI could boost efficiency by 25%. That’s a big deal for future gadgets—check Precision Components.

Green Power

Ceramic sensors will help solar grids. The market might double by 2032—learn more at New Energy.

Cool Future

New ideas keep ceramics in sensor technology growing. They’ll make life easier and greener—see Ceramic Benefits.

Wrap-Up: Power Up with Eshino Precision

Why Ceramics Are Awesome

Ceramics in sensor technology are tough, accurate, and last forever. They help cars, rockets, hospitals, and factories work better.

At Eshino Precision, we make ceramic parts like substrates and zirconia rods. We’ve got your sensor needs covered!

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.