Table of Contents

Did you know? Ceramic washers can handle super hot temperatures up to 2000°C and resist nasty chemicals! These tiny, disc-shaped heroes are changing industries like aerospace and electronics. At Eshino Precision, we make top-notch ceramic washers to keep machines running smoothly. Let’s dive into why they’re awesome and how to use them!

| Feature | Why It’s Cool |

|---|---|

| Heat Resistance | Works at 2000°C without melting! |

| Corrosion Resistance | Stays strong against acids and salts. |

| Electrical Insulation | Keeps electricity from causing trouble. |

| Market Growth | Worth $1.39 billion by 2025! |

Introduction

Why Ceramic Washers Matter

Hey there! Imagine a tiny part that can handle crazy heat, tough chemicals, and even stop electricity from messing things up. That’s a ceramic washer! These flat, ring-shaped components are super important in machines. For example, they help planes fly safely and keep medical devices working perfectly. Plus, the market for ceramic parts is growing fast. In fact, it’s expected to hit $1.39 billion by 2025, growing at 7.5% every year, according to industry reports.

Eshino Precision’s Role

At Eshino Precision, we’re experts in making ceramic washers and other cool parts like ceramic seals and ceramic rods. Our washers are used in industries like aerospace and electronics. So, whether you’re an engineer or a buyer, this guide will explain everything about ceramic washers in a simple way!

What’s Coming Up

First, we’ll explain what a ceramic washer is. Then, we’ll explore where they’re used, their benefits, and the different types. By the end, you’ll know why ceramic washers are a game-changer. Let’s get started!

Zirconia Ceramic Washer: Tough and strong!

Silicon Carbide Washer: Super heat-resistant!

What is a Ceramic Washer?

The Basics of Ceramic Washers

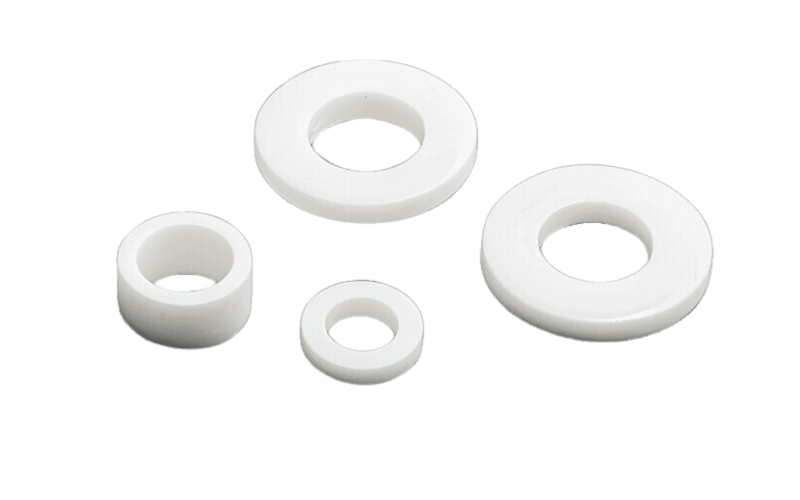

A ceramic washer is a small, flat ring with a hole in the middle. It’s made from special materials called ceramics, like alumina or zirconia. Unlike metal or plastic washers, ceramic washers are super tough. They help spread the weight of bolts or screws, stop leaks, or keep electricity from causing problems. Think of them as tiny shields for your machines!

How They’re Different

Now, you might wonder: why not use metal? Well, metal washers can rust or melt in hot places. Ceramic washers, however, can handle extreme heat and won’t corrode. For example, they’re perfect for chemical plants where acids are everywhere. Plus, they don’t conduct electricity, which is great for electronics.

Why They’re Awesome

According to Dr. Emily Chen, a materials scientist, “Ceramic washers are a game-changer because they combine strength with insulation, making them ideal for high-tech industries.” At Eshino Precision, we craft these washers to be precise and reliable. Want to learn more about ceramic materials? Check out our guide on structural ceramics.

Applications of Ceramic Washers

Where You’ll Find Them

High-Tech Uses

Next, they’re big in electronics. Ceramic washers stop electricity from causing short circuits in devices like computers. In medical tools, they’re used because they’re safe for the body. For example, they help make implants that last a long time. Also, in chemical plants, they resist nasty chemicals.

Green Energy

Finally, ceramic washers are helping the planet! They’re in wind turbines and solar panels, where they handle tough weather. Their durability makes green energy machines last longer. Want to see how ceramics help in other machines? Read about ceramic bearings.

Advantages of Using Ceramic Washers

Super Strong Features

So, why choose a ceramic washer? First, they can handle crazy heat—up to 2000°C! That’s way hotter than a pizza oven. Also, they don’t rust or corrode, even if they’re around acids or salty water. This makes them perfect for corrosion-resistant jobs.

Saves Money and Time

Another big win? They last a super long time. Because they’re so durable, you won’t need to replace them often, which saves money. Plus, they’re lightweight, which is great for airplanes that need to stay light. Check out how ceramics cut costs in our blog on reducing maintenance costs.

Special Powers

Lastly, ceramic washers don’t conduct electricity, which is a huge deal for electronics. They’re also non-magnetic, so they won’t mess with sensitive equipment. For more on why ceramics are awesome, see our guide to zirconia ceramics.

Types of Ceramic Washers

Different Materials, Different Powers

Common Types

Here’s a table to show the types of ceramic washers and what they’re best for:

| Material | Superpower | Best For |

|---|---|---|

| Alumina | Hard and wear-resistant | Electronics, machines |

| Zirconia | Super strong and tough | Airplanes, medical tools |

| Silicon Carbide | Handles heat and wear | Engines, tough jobs |

| Silicon Nitride | Strong and shock-resistant | Cars, turbines |

| Steatite | Cheap and insulating | Electrical parts |

Why It Matters

Choosing the right type is key. For instance, if you need a ceramic washer for a hot engine, go for silicon carbide. But if it’s for a computer, alumina is your best bet. Want to learn more? Check out our guide on zirconia vs. alumina.

How to Choose the Right Ceramic Washer

Think About the Job

Picking the perfect ceramic washer is like choosing the right tool. First, think about where it’ll be used. Is it super hot, like in an airplane engine? Or is it around chemicals, like in a factory? This helps you pick the best material.

Check the Fit

Next, make sure the washer fits your bolts or screws. Ceramic washers come in standard sizes, like metric or inch, but we can make custom ones at Eshino Precision. Also, consider how much money you want to spend. Ceramics can be pricier than metal, but they last longer.

Ask the Experts

Still unsure? Talk to us! We can help you find the right ceramic washer. Dr. John Lee, an engineer, says, “Working with a trusted supplier like Eshino Precision ensures you get the exact ceramic washer for your needs.” Read more about choosing materials in our blog on technical ceramics.

Manufacturing Process of Ceramic Washers

Making the Magic Happen

Creating a ceramic washer is like baking a super tough cookie. First, we start with ceramic powder, like silicon carbide. Then, we press it into a washer shape using a machine. This step is called powder compaction.

Cooking and Shaping

Next, we “cook” the washer in a super hot oven called a kiln. This process, called sintering, makes thehints at how tough ceramics can be. Finally, we polish and shape it to be super precise. Want to know more? Check out our guide on ceramic manufacturing.

Why It’s Cool

This process makes ceramic washers strong and exact, so they work perfectly in machines. At Eshino Precision, we use the latest tech to make top-quality washers.

Ceramic Washers vs. Other Materials

Ceramic vs. Metal

Ceramic washers are different from metal or plastic washers. For example, ceramics can handle way more heat—up to 2000°C! Metal washers might melt at 800°C, and plastic ones only go to 200°C. Plus, ceramics don’t rust, unlike metal.

Here’s a Quick Comparison

| Feature | Ceramic | Metal | Plastic |

|---|---|---|---|

| Heat Resistance | Up to 2000°C | Up to 800°C | Up to 200°C |

| Corrosion Resistance | Excellent | Okay | Good |

| Electrical Insulation | Yes | No | Yes |

| Cost | Higher | Medium | Lower |

When to Choose Ceramic

Pick ceramic washers for super tough jobs, like in airplanes or electronics. But be careful—they can break if dropped, unlike metal. Learn more in our blog on ceramics vs. other materials.

Market Trends and Statistics

Growing Fast

The market for ceramic washers and other ceramic parts is booming! In 2023, it was worth $1.2 billion, and by 2025, it’ll hit $1.39 billion, growing 7.5% every year, says DataIntelo. Why? Because industries like aerospace and electronics love them.

Big Drivers

For example, airplane makers like Boeing are building more planes—50 a month by 2025! Also, electronics are getting smaller, needing tiny, tough washers. Plus, green energy like wind turbines uses ceramics for durability.

| Year | Market Size | Growth Rate |

|---|---|---|

| 2023 | $1.2 billion | – |

| 2025 | $1.39 billion | 7.5% |

| 2032 | $2.3 billion | 7.5% |

Why It’s Exciting

This growth means more chances to use ceramic washers. At Eshino Precision, we’re ready to help! Read about ceramics in industry at our blog.

Case Studies or Examples

Electronics Win

In chip-making machines, ceramic washers keep things cool and insulated. For example, alumina washers stop short circuits, making chips faster and better.

Airplane Power

In jet engines, zirconia washers handle crazy heat and save weight. This makes planes fly farther using less fuel, which is awesome!

Medical Marvel

In medical implants, alumina washers are safe for the body. They help tools last longer, keeping patients healthy. See more examples in our custom parts guide.

Maintenance and Care

Keep Them Safe

Ceramic washers are tough, but they need a little care. First, don’t drop them—they can crack. Also, check them now and then for tiny cracks, especially in hard jobs like engines.

Easy Cleaning

To clean a ceramic washer, use a soft cloth and gentle soap. Don’t use rough stuff—it might scratch them. This keeps them shiny and strong.

Long Life

With good care, ceramic washers last ages. Want tips on making parts last? Read our blog on zirconia durability.

Common Questions About Ceramic Washers

What are ceramic washers used for?

Ceramic washers are used in airplanes, cars, electronics, and more. They handle heat, chemicals, and electricity.

What are the benefits?

They resist heat (up to 2000°C), corrosion, and electricity. Plus, they’re super durable and lightweight.

How do they compare to metal washers?

Ceramic washers beat metal in heat and corrosion resistance but can be brittle. Metal is tougher but rusts.

What materials are used?

Alumina, zirconia, silicon carbide, silicon nitride, and steatite are common. Each has unique strengths.

Are they good for hot places?

Yes! Ceramic washers can take up to 2000°C, perfect for hot jobs.

Can they handle chemicals?

Absolutely! They resist acids and other nasty stuff, great for chemical plants.

Where can I buy them?

Get them from Eshino Precision or other suppliers like Extreme Bolt.

Conclusion

Why Ceramic Washers Rock

Ceramic washers are tiny but mighty! They handle crazy heat, tough chemicals, and electricity, making them perfect for airplanes, electronics, and more. Plus, the market is growing fast—$1.39 billion by 2025! Whether you need a washer for a car or a medical tool, ceramics are the way to go.

Learn More

Want to dive deeper? Explore our blogs on high-temperature ceramics or custom ceramic parts. Your next big idea starts here!

External Links

Ready to Transform Your Engineering Solutions?

Ready to try ceramic washers? At Eshino Precision, we make top-quality washers and other parts like ceramic rods and seals. Contact us today to find the perfect washer for your project. Let’s make your machines tougher and better!