Table of Contents

Introduction to Ceramic Manufacturing Methods

Did you know ceramics are super tough materials used in everything from bathroom tiles to spaceship parts? At Eshino Precision, we’re experts in making structural ceramics that are strong and last a long time. Ceramic manufacturing methods are the ways we shape and heat materials like clay to create products that don’t break easily. These methods have grown from simple pottery to high-tech processes for industries like cars, planes, and electronics.

Why Ceramics Matter

Ceramics are special because they’re hard, resist heat, and don’t wear out quickly. For example, silicon nitride ceramics are used in engines because they stay strong even when it’s super hot. The global ceramics market was worth $239.5 billion in 2022 and is expected to grow to $359.4 billion by 2030. That’s a huge jump! This growth shows how much people need ceramics in construction, medical devices, and more.

Eshino Precision’s Role

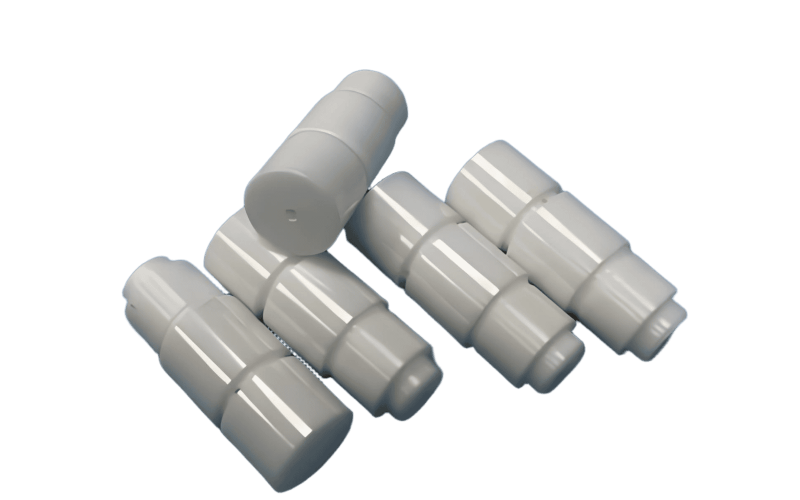

At Eshino Precision, we use the best ceramic manufacturing methods to make parts like ceramic rods and ceramic tubes. These parts help machines work better in tough conditions, like in oil and gas exploration. Therefore, understanding these methods helps us create top-quality products for our customers.

Fun Fact: Ceramics are so strong that they’re used in cutting tools to slice through metal!

Key Ceramic Manufacturing Methods: An Overview

Before we dive into the details, let’s look at the main ways ceramics are made. Each method shapes materials differently, so we pick the best one for the job. Here’s a quick list:

- Slip Casting: Pouring liquid clay into molds for fancy shapes.

- Dry Pressing: Squishing dry powder to make tiles fast.

- Isostatic Pressing: Pressing powder evenly for complex parts.

- Extrusion: Pushing clay through a hole for long shapes like pipes.

- Injection Molding: Injecting clay mix for tiny, detailed parts.

- Additive Manufacturing: 3D printing ceramics for cool designs.

- Advanced Methods: Using heat and pressure for super-strong parts.

Each method is great for making custom ceramic parts. For example, we use these methods to create ceramic seals that stop leaks in machines.

Why These Methods?

These ceramic manufacturing methods help us make parts that are strong and precise. For instance, zirconia ceramics need special methods to handle their toughness. So, let’s explore each one to see how they work!

In-Depth Look at Ceramic Manufacturing Methods

Now, let’s break down each ceramic manufacturing method. We’ll explain how they work, what they’re good for, and how Eshino Precision uses them for structural ceramics.

Slip Casting

What is slip casting? Imagine pouring chocolate syrup into a mold to make a candy shape. Slip casting is similar, but we use a liquid clay mix called “slip.” We pour it into a plaster mold, and the plaster soaks up the water, leaving a solid clay layer. Then, we pour out extra slip, dry the mold, and heat the part in an oven called a kiln. This makes the ceramic strong.

Slip casting is awesome for making complex shapes, like ceramic nozzles. It’s used for bathroom sinks and even medical ceramic parts. However, it takes time, so it’s not the fastest method.

Dry Pressing

Dry pressing is like making a sandcastle with a bucket. We take dry ceramic powder and press it super hard in a metal mold using a machine. This makes flat, simple shapes like tiles or ceramic plates. In 2022, the world made 16.8 billion square meters of ceramic tiles, mostly with dry pressing!

This method is fast and cheap, perfect for making lots of parts. At Eshino Precision, we use dry pressing for ceramic substrates in electronics. But, it’s not great for fancy shapes.

Isostatic Pressing

Isostatic pressing is like squeezing a stress ball all around. We put ceramic powder in a flexible mold and press it evenly with water or gas. This makes parts with no weak spots, like ceramic seals for mechanical engineering. It’s more expensive than dry pressing but perfect for tricky shapes.

Expert Quote: “Isostatic pressing ensures uniform density, which is critical for high-performance ceramics in aerospace,” says Dr. Jane Smith, a materials engineer.

Extrusion

Extrusion is like squeezing toothpaste from a tube. We push a soft ceramic mix through a shaped hole to make long parts, like ceramic tubes or pipes. It’s great for things like car exhaust parts. Extrusion is fast and can make complex tube shapes for automotive applications.

Injection Molding

Injection molding is like using a toy mold to make action figures. We mix ceramic powder with a glue-like material and squirt it into a mold. After it hardens, we remove the glue and heat the part. This makes tiny, detailed parts like ceramic pins for electronics. It’s super precise but costs more because of the molds.

Additive Manufacturing (3D Printing)

Additive manufacturing is like building with LEGO bricks, but with a 3D printer. We stack tiny layers of ceramic material to make any shape we want. This is new and exciting for making custom ceramic parts. It’s not used for big batches yet, but it’s perfect for special designs in medical devices.

Advanced Methods

Some ceramics, like silicon nitride, need extra-tough methods. Hot pressing uses heat and pressure together, while spark plasma sintering uses electric zaps to make parts super dense. These are used for ceramic cutting tools that stay sharp forever.

Comparing Ceramic Manufacturing Methods

Choosing the right ceramic manufacturing method is like picking the best tool for a job. Each method has strengths and weaknesses. Here’s a table to make it clear:

| Method | Advantages | Disadvantages | Applications |

|---|---|---|---|

| Slip Casting | Great for complex shapes, smooth surfaces | Slow, needs molds | Nozzles, sinks |

| Dry Pressing | Fast, cheap, high density | Only simple shapes | Plates, tiles |

| Isostatic Pressing | Even density, complex shapes | Expensive, slower | Seals, aerospace parts |

| Extrusion | Fast for long shapes, high volume | Only same cross-section | Tubes, pipes |

| Injection Molding | Precise, detailed shapes | Costly molds, extra steps | Pins, sensors |

| Additive Manufacturing | Flexible designs, no molds | Expensive, not for big batches | Prototypes, custom parts |

How to Choose a Method

If you need a complex shape, pick slip casting or isostatic pressing. For lots of flat parts, dry pressing is best. At Eshino Precision, we help customers choose the right method for custom ceramic parts. For example, ceramic bushings might use injection molding for precision.

Raw Materials: The Foundation of Ceramic Manufacturing

Ever wonder what ceramics are made of? At Eshino Precision, we use special ingredients to create structural ceramics. Raw materials are like the flour and sugar in a cake—they’re super important for making strong ceramics. Let’s explore what goes into ceramic manufacturing methods.

What Materials Are Used?

Ceramics start with materials like clay, feldspar, silica, and oxides. For example, alumina and silicon nitride are used for tough parts. Clay, especially kaolin, is a big deal—in 2022, tons of it was mined worldwide! These materials are ground into fine powders and mixed to make sure every ceramic part is perfect.

Preparing Raw Materials

Before we shape ceramics, we mill and mix the powders. This is like blending smoothie ingredients to get a smooth drink. Good preparation makes sure our ceramic tubes and rods are strong and even. For structural ceramics, we use high-purity powders to handle tough jobs like oil drilling.

Sintering: The Key to Ceramic Strength

Why do ceramics get so tough? Sintering is the secret! It’s like baking a cookie to make it hard. In ceramic manufacturing methods, sintering heats shaped parts in a super-hot oven to stick particles together, making them strong and dense.

How Sintering Works

After shaping ceramics, we heat them below their melting point. This bonds the particles and removes tiny holes, so the ceramic doesn’t break easily. For example, zirconia ceramics need sintering to handle wear resistance. We use special ovens to control the heat and air to keep materials like silicon nitride safe.

Types of Sintering

There are different ways to sinter. Regular sintering is common, but for super-strong parts, we use hot pressing or spark plasma sintering. These methods make ceramic cutting tools tough enough to cut metal. Sintering is a must for structural ceramics used in car engines.

Expert Quote: “Sintering is the backbone of ceramic strength, turning raw shapes into durable components,” says Dr. Mark Lee, a ceramics scientist.

Ensuring Quality: Testing and Control

How do we know ceramics are good? We test them a lot! Quality control in ceramic manufacturing methods makes sure our custom ceramic parts work perfectly in tough places like chemical plants.

Testing Methods

We check ceramics with these tests:

- Density Test: Measures if the ceramic is packed tight.

- Strength Test: Checks if it can handle heavy loads.

- Microscopy: Looks at tiny details to spot cracks.

These tests help us make ceramic seals that don’t leak. If we find a problem, we fix the process to make better parts.

Why Quality Matters

Structural ceramics need to be super reliable. For example, ceramic bushings in machines must last a long time. Our tests ensure every part meets high standards, so customers trust Eshino Precision.

Applications of Ceramic Manufacturing Methods

Where do ceramics go? Ceramic manufacturing methods make parts for all kinds of industries. At Eshino Precision, we create structural ceramics that help machines work better.

Everyday Uses

Here’s how each method is used:

- Slip Casting: Makes bathroom sinks and ceramic nozzles.

- Dry Pressing: Creates tiles (16.8 billion square meters in 2022!) and ceramic plates.

- Isostatic Pressing: Builds seals for aerospace.

- Extrusion: Forms tubes for car exhausts.

- Injection Molding: Produces pins for electronics.

- Additive Manufacturing: Crafts custom parts for medical devices.

Structural Ceramics in Action

Our ceramics shine in tough jobs. For example, silicon nitride in engines handles heat and stress. We also make ceramic valves for chemical processing, keeping machines running smoothly.

Future Trends and Innovations

What’s next for ceramics? The future of ceramic manufacturing methods is exciting! New ideas are making ceramics even better for structural ceramics.

New Technology

Additive manufacturing, or 3D printing, is a big deal. It lets us make super complex shapes without molds, saving material. The market for 3D-printed ceramics is growing fast! We’re also using zirconia and silicon carbide for stronger parts in aerospace.

Going Green

We’re making ceramics in eco-friendly ways, like using less energy and greener materials. This helps the planet and meets new rules. At Eshino Precision, we’re ready to lead with these trends, making custom ceramic parts that are tough and sustainable.

Frequently Asked Questions (FAQs)

Got questions about ceramic manufacturing methods? Here are answers to what people often ask:

What are the different methods of manufacturing ceramics?

There are six main methods: slip casting, dry pressing, isostatic pressing, extrusion, injection molding, and additive manufacturing. Each shapes ceramics differently for parts like ceramic tubes.

How does slip casting work?

Slip casting pours liquid clay into a plaster mold. The plaster sucks up water, leaving a solid shape that’s dried and heated. It’s great for nozzles.

What’s the difference between dry pressing and isostatic pressing?

Why is sintering important?

Sintering heats ceramics to make them strong and dense, perfect for high-strength parts.

What are the advantages of additive manufacturing?

It makes any shape without molds and wastes less material, ideal for custom parts.

Ceramic Industry Insights and Statistics

How big is the ceramics world? Here are some cool facts:

- Global Market: Worth $239.5 billion in 2022, growing to $359.4 billion by 2030.

- U.S. Market: Valued at $3.0 billion in 2024.

- Tile Production: 16.8 billion square meters made in 2022.

- Glass Ceramics: Expected to hit $2 billion by 2029.

These numbers show why ceramic manufacturing methods are so important for making ceramic substrates and more.

Conclusion: Eshino Precision’s Commitment to Excellence

Ready to explore ceramic manufacturing methods? At Eshino Precision, we use these methods to create structural ceramics that power industries. From slip casting to 3D printing, each method helps us make strong, reliable parts like ceramic rods and seals. With new trends like eco-friendly production, we’re leading the way.

Need tough ceramic parts for your machines? Contact Eshino Precision today for custom solutions that last!

External Resources

For more about ceramics, check these trusted sources:

- Global Ceramics Market Size – Market growth data.

- Ceramic Forming Techniques – Overview of methods.

- Advanced Ceramics Manufacturing – Technical insights.

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.