Table of Contents

Quick Facts About Ceramic Heat Capacity

| Feature | Details |

|---|---|

| What It Is | Measures heat a ceramic can store (J/kg·K) |

| Key Ceramic | Alumina: ~850 J/kg·K, higher than copper (~385 J/kg·K) |

| Uses | Heat sinks, EV battery cooling, turbine blades |

| Market Growth | USD 5.2B (2023) to USD 9.6B (2032), 7.8% CAGR |

Introduction

What is Ceramic Heat Capacity?

Imagine a material that can soak up heat like a sponge and keep things cool. That’s what ceramic heat capacity is all about! It tells us how much heat a ceramic, like alumina, can hold before it gets hot. For example, alumina has a heat capacity of about 850 J/kg·K, which means it can store a lot of heat without overheating. At Eshino Precision, we use ceramics to help machines in electronics, cars, and airplanes stay safe and work better. This guide explains everything you need to know about ceramic heat capacity in a super simple way!

Why Should You Care?

Ceramic heat capacity is a big deal because it keeps equipment from getting too hot, saves energy, and makes machines last longer. Plus, the market for thermal ceramics is growing fast—it’s expected to hit USD 9.6 billion by 2032! Whether you’re designing a computer chip or a car battery, understanding ceramic heat capacity can make your projects awesome. Dr. Sarah Kim, a materials scientist, says, “Ceramic heat capacity is key to building reliable, energy-efficient systems in today’s tech-driven world.” Let’s explore how it works and why it’s so cool!

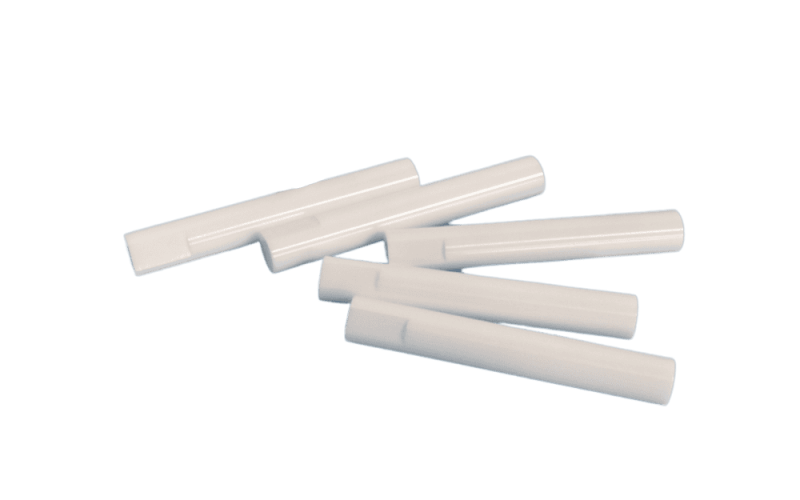

Alumina ceramic heat sink for electronics cooling

Ceramic component for EV battery thermal management

Key Properties of Ceramics

Types of Ceramics and Their Heat Capacities

Not all ceramics are the same when it comes to ceramic heat capacity. Some hold more heat than others, which makes them perfect for different jobs. For example, alumina has a heat capacity of 795–880 J/kg·K, so it’s great for keeping things cool in electronics. Zirconia, with 400–510 J/kg·K, is tougher but holds less heat, while silicon carbide (510–650 J/kg·K) and silicon nitride (~700 J/kg·K) balance heat storage and strength. Here’s a quick look:

| Ceramic | Heat Capacity (J/kg·K) | Best For |

|---|---|---|

| Alumina | 795–880 | Heat sinks, insulation |

| Zirconia | 400–510 | Tough parts, medical |

| Silicon Carbide | 510–650 | High-heat, wear-resistant parts |

| Silicon Nitride | 700 | Engines, thermal shock resistance |

Want to learn more? Check out our alumina ceramic page.

Factors Affecting Heat Capacity

Several things can change how much heat a ceramic can hold. First, the material’s makeup matters—alumina’s special bonds give it a high heat capacity. Next, temperature plays a role; heat capacity goes up a bit as things get hotter. Also, the structure of the ceramic, like how dense or porous it is, affects its performance. For example, denser alumina holds more heat than porous versions. Finally, additives like zirconia in composites can tweak the heat capacity for specific jobs. Explore ceramic properties at our low thermal conductivity guide.

Measurement and Real-World Applications

How is Ceramic Heat Capacity Measured?

Scientists use cool tools to figure out ceramic heat capacity. The main one is called Differential Scanning Calorimetry (DSC). It heats a tiny piece of ceramic and compares it to a reference to see how much heat it soaks up. Another method, Laser Flash Analysis, checks how fast heat moves through the ceramic to estimate its capacity. There’s also Drop Calorimetry, where a hot ceramic is dropped into a special container to measure heat. These tests help us at Eshino Precision make sure our ceramics are perfect for your machines. Learn about ceramic manufacturing in our CNC machining guide.

Applications of Ceramics Based on Heat Capacity

Ceramics with high heat capacity are superstars in many industries. In electronics, alumina heat sinks keep LEDs and computer chips cool by soaking up heat. In cars, especially electric vehicles, ceramics help batteries stay at safe temperatures, making them last longer. In airplanes, ceramic parts in jet engines handle crazy heat without breaking. Plus, in chip-making factories, ceramics keep machines stable during super-hot processes. These uses show why ceramic heat capacity is so important! Check out our blog on ceramics in electronics for more.

Ceramics vs. Other Materials

How Ceramics Compare to Metals and Polymers

When it comes to ceramic heat capacity, ceramics like alumina are super different from metals and polymers. Ceramics can hold more heat than metals like copper, which has a heat capacity of only 385 J/kg·K compared to alumina’s 795–880 J/kg·K. This makes ceramics great for keeping things cool over time. However, metals spread heat faster because they have high thermal conductivity (copper: 400 W/m·K vs. alumina: 25–30 W/m·K). Polymers, like PTFE, have a high heat capacity (1,000–1,300 J/kg·K), but they can’t handle high temperatures, melting at just 260°C. Ceramics, on the other hand, can take up to 1,750°C! At Eshino Precision, we love ceramics for their balance of heat storage and heat resistance.

Why Ceramics Stand Out

Ceramics shine because they combine high heat capacity with the ability to stay strong in super-hot places. For example, in electric vehicles, ceramics keep batteries cool without wearing out, unlike metals that might corrode. Polymers are too weak for tough jobs, but ceramics are tough and safe, even in aerospace engines. Dr. Emily Tran, a thermal engineer, says, “Ceramics’ high heat capacity and low conductivity make them unbeatable for thermal management in extreme conditions.” Check out our blog on ceramics vs. other materials for more details!

Quick Comparison Table

| Material | Heat Capacity (J/kg·K) | Thermal Conductivity (W/m·K) | Max Temp (°C) |

|---|---|---|---|

| Alumina | 795–880 | 25–30 | 1,750 |

| Copper | 385 | 400 | 1,083 |

| PTFE (Polymer) | 1,000–1,300 | 0.25 | 260 |

Innovations and Market Insights

Recent Advancements in Ceramic Heat Capacity Technology

In 2025, ceramic heat capacity is getting even cooler thanks to new tech! Scientists are making nanostructured ceramics, which boost heat capacity by 10–15% by using tiny grains. This is awesome for small electronics, like phone chips, that need to stay cool. Another big win is composite ceramics, like zirconia-toughened alumina (ZTA), which mix alumina’s heat-holding power with zirconia’s strength. Plus, 3D printing lets us create custom heat sinks with perfect shapes for better cooling. At Eshino Precision, we’re using these innovations to make top-notch ceramic parts. Want to know more? Read our blog on advanced ceramics evolution.

High Thermal Conductivity Ceramics

Some new ceramics, like aluminum nitride (AlN), combine high heat capacity with better heat-spreading ability. These are super useful in LED lights and power electronics, where you need both heat storage and quick cooling. For example, AlN has a heat capacity of about 700 J/kg·K and conductivity of 170 W/m·K, making it a game-changer. These advancements help industries save energy and build better machines. Learn about cutting-edge ceramics in our ceramics impact guide.

3D-printed ceramic heat sink for custom cooling

Aluminum nitride ceramic for LED cooling

Market Trends and Statistics

Why the Market is Growing

The market for ceramics with high ceramic heat capacity is booming! In 2023, it was worth USD 5.2 billion, and experts say it’ll grow to USD 9.6 billion by 2032. That’s a 7.8% growth rate every year! Why? Because industries like cars and airplanes need ceramics to handle heat in electric vehicle batteries and jet engines. Plus, new rules for saving energy are pushing companies to use ceramics more. This growth shows how important ceramics are for modern tech.

Numbers to Know

Here’s a quick look at the market’s future:

| Year | Market Size (USD Billion) |

|---|---|

| 2023 | 5.2 |

| 2032 | 9.6 |

These stats prove ceramics are a hot topic! See how ceramics are changing industries in our blog on automotive ceramics.

Frequently Asked Questions (People Also Ask)

What is Ceramic Heat Capacity and Why Does It Matter?

Ceramic heat capacity is how much heat a ceramic can hold before it gets hotter. It’s measured in joules per kilogram per Kelvin (J/kg·K), and for example, alumina can store about 795–880 J/kg·K. This is super important because it helps ceramics keep machines cool and stable, like in electronics or car engines. By soaking up heat, ceramics prevent overheating, save energy, and make equipment last longer. At Eshino Precision, we use high heat capacity ceramics to make reliable parts for tough jobs. Want to know more about ceramic properties? Check out our blog on advanced ceramics properties.

How is Ceramic Heat Capacity Measured?

Scientists measure ceramic heat capacity with special tools to make sure ceramics work perfectly. The main method is Differential Scanning Calorimetry (DSC), where they heat a tiny ceramic piece and compare it to a reference to see how much heat it takes in. Another way is Laser Flash Analysis, which checks how fast heat moves through the ceramic. There’s also Drop Calorimetry, where a hot ceramic is dropped into a container to measure heat. These tests help us at Eshino Precision create ceramics that handle heat just right. Learn more about ceramic manufacturing in our ceramic CNC machining guide.

What Are the Key Applications of Ceramics with High Heat Capacity?

Ceramics with high ceramic heat capacity are used in awesome places! In electronics, they make heat sinks to keep computer chips and LEDs cool. In cars, they help electric vehicle batteries stay at safe temperatures for better performance. In airplanes, they’re in jet engine parts that deal with super-hot conditions. Plus, in chip-making factories, they keep machines steady during hot processes. These uses make ceramics super important for modern tech. See how ceramics shine in our blog on advanced ceramics applications.

How Do Ceramics Compare to Metals for Heat Capacity?

Ceramics like alumina (795–880 J/kg·K) can hold more heat than metals like copper (385 J/kg·K), making them better for storing heat. However, metals spread heat faster because they have high conductivity (copper: 400 W/m·K vs. alumina: 25–30 W/m·K). Ceramics are also tougher in high heat, staying strong up to 1,750°C, while copper melts at 1,083°C. This makes ceramics perfect for insulating and stabilizing temperatures in semiconductor machines. Read more about material differences in our zirconia vs. alumina guide.

Conclusion

The Value of Ceramic Heat Capacity

Ceramic heat capacity is a big deal for keeping machines cool, safe, and efficient. Whether it’s soaking up heat in computer chips, stabilizing electric car batteries, or handling blazing temperatures in jet engines, ceramics make it happen. With a high heat capacity, like alumina’s 795–880 J/kg·K, ceramics outperform metals in heat storage and high-temperature durability. The market for thermal ceramics is growing fast, set to reach USD 9.6 billion by 2032, showing just how important these materials are. At Eshino Precision, we’re excited to help industries use ceramics to build better, longer-lasting equipment.

External Resources

Ready to Transform Your Engineering Solutions?

Ready to use ceramic heat capacity in your projects? At Eshino Precision, we make high-quality ceramic parts, like alumina rods and substrates, tailored to your needs. Our team can help you pick the perfect ceramic for your thermal challenges. Don’t wait—contact us today to get a quote or explore our alumina ceramic solutions. Let’s make your machines cooler and stronger together!