Table of Contents

Did you know ceramic fasteners can withstand temperatures up to 1500°C and resist harsh chemicals? At Eshino Precision, we specialize in these super-tough components. This guide explains why ceramic fasteners are game-changers for industries like aerospace and medical. Let’s dive in!

Introduction: Why Ceramic Fasteners Matter

Ceramic fasteners are not your average screws or bolts. Made from advanced materials like alumina and zirconia, they handle extreme conditions where metal fails. Imagine a screw that doesn’t rust, melt, or conduct electricity—that’s a ceramic fastener! They’re lightweight, durable, and perfect for high-tech industries.

Here’s a quick look at why they’re special:

| Feature | Benefit |

|---|---|

| Temperature Resistance | Up to 1500°C |

| Corrosion Resistance | Immune to most chemicals |

| Electrical Insulation | Non-conductive |

| Market Growth | USD 2.66 billion in 2025, 6.5% CAGR |

What Makes Them Unique?

Ceramic fasteners shine in tough environments. For example, in aerospace, they secure engine parts under extreme heat. In medical applications, they’re used in implants because they’re safe for the body. Their high-temperature resistance and corrosion resistance make them stand out.

Why Read This Guide?

This article breaks down everything about ceramic fasteners in simple terms. Whether you’re an engineer or a curious reader, you’ll learn what they are, their benefits, and where they’re used. Plus, we’ll answer common questions to help you decide if they’re right for your project.

“Ceramic fasteners are revolutionizing industries by offering unmatched durability in extreme conditions,” says Dr. Emily Chen, a materials engineer at Advanced Ceramics Solutions.

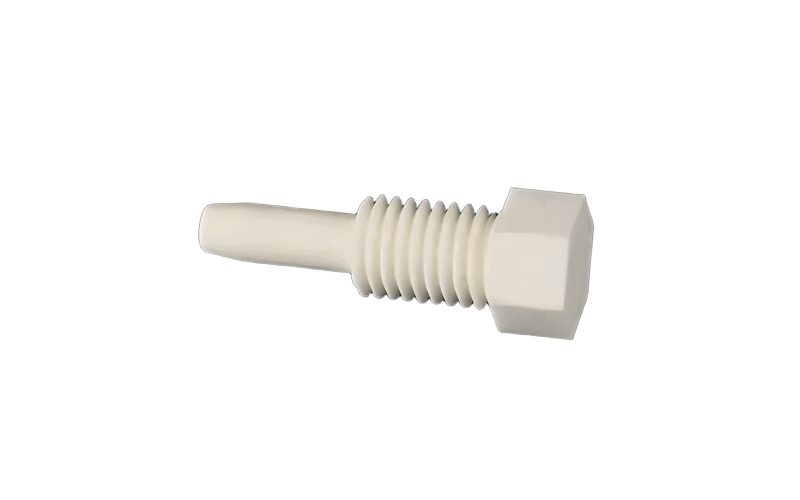

Zirconia Ceramic Fastener

Alumina Ceramic Fastener

What Are Ceramic Fasteners?

Ceramic fasteners are special hardware like screws, bolts, and nuts made from advanced ceramics. Unlike regular metal or plastic fasteners, they’re built for tough conditions. Think of them as superheroes of the fastener world, handling heat, chemicals, and electricity without breaking a sweat.

How Are They Made?

These fasteners are crafted from materials like silicon nitride or silicon carbide. The process involves shaping and heating these ceramics to create strong, precise components. This makes them non-conductive and non-magnetic, perfect for sensitive applications.

Why Are They Special?

Ceramic fasteners don’t rust or melt, even in extreme heat. They’re also super durable, resisting wear and tear. For example, in electronics, they prevent electrical shorts. At Eshino Precision, we produce these for industries needing top-notch performance.

Common Uses

You’ll find ceramic fasteners in places like airplane engines, medical implants, and chemical plants. Their ability to stay strong in harsh environments makes them a go-to choice for high-stakes projects.

Advantages of Using Ceramic Fasteners

Ceramic fasteners have amazing benefits that make them stand out. They’re like the ultimate tool for tough jobs, offering features metal fasteners can’t match. Let’s explore why they’re so awesome.

Super Heat Resistance

Ceramic fasteners can handle temperatures up to 1500°C. That’s way hotter than most metals, which start to weaken at 500°C. This makes them perfect for aerospace engines or furnaces.

No Rust, Ever

Unlike metal, ceramic fasteners don’t rust. They resist acids and chemicals, so they’re great for chemical processing. This means less maintenance and longer-lasting equipment.

Electrical Insulation

These fasteners don’t conduct electricity. This is a big deal in electronics, where they prevent unwanted currents. They’re also lightweight, helping reduce weight in cars and planes.

Other Cool Features

- Non-Magnetic: Safe for medical devices like MRI machines.

- Wear Resistance: Lasts longer in rough conditions.

- Lightweight: Helps make vehicles and machines more efficient.

As Dr. Chen notes, “Their unique properties make ceramic fasteners indispensable for cutting-edge technology.”

Applications of Ceramic Fasteners in Various Industries

Ceramic fasteners are used in many industries because they’re so tough. They’re like the perfect puzzle piece for machines that need to work in extreme conditions. Let’s see where they’re used.

Aerospace: Sky-High Performance

In aerospace, ceramic fasteners hold engine parts together under intense heat. They’re also lightweight, which saves fuel. For example, they secure turbine blades that face temperatures over 1000°C.

Medical: Safe and Strong

In medical fields, ceramic fasteners are used in implants and surgical tools. They’re safe for the body and don’t interfere with MRI scans. Their high reliability ensures patient safety.

Electronics: No Sparks Here

Ceramic fasteners are perfect for electronics. They don’t conduct electricity, so they’re used in circuit boards and high-voltage systems. This keeps devices safe and reliable.

More Industries

- Automotive: In high-performance cars, they handle hot engines and exhausts.

- Chemical Processing: Resist corrosion in harsh chemical plants.

- Green Energy: Used in solar panels and wind turbines for durability.

Explore our ceramic threaded parts for your industry needs.

Comparing Ceramic Fasteners to Traditional Metal Fasteners

Choosing between ceramic fasteners and metal fasteners can be tricky. Each has its strengths, but ceramic fasteners are often better for extreme conditions. Let’s break down how they compare so you can pick the right one for your project.

Key Differences at a Glance

Here’s a simple table to show how ceramic fasteners stack up against metal ones:

| Feature | Ceramic Fasteners | Metal Fasteners |

|---|---|---|

| Temperature Resistance | Up to 1500°C | Up to 500°C |

| Corrosion Resistance | Immune to most chemicals | Varies (e.g., stainless steel resists rust) |

| Electrical Conductivity | Non-conductive | Conductive |

| Weight | Lighter | Heavier |

| Strength | High compressive strength | High tensile strength |

| Cost | Higher | Lower |

This table makes it clear: ceramic fasteners shine in heat and corrosion, while metal fasteners are stronger and cheaper.

When to Choose Ceramic Fasteners

Use ceramic fasteners when you need something that won’t melt, rust, or conduct electricity. For example, in aerospace, they’re perfect for hot engines. In electronics, they prevent electrical issues. However, they’re brittle, so you must handle them carefully to avoid breaking.

When Metal Fasteners Work Better

Metal fasteners, like those made of stainless steel, are great for everyday projects. They’re tougher in tension, meaning they can handle pulling forces better. They’re also easier to install and cost less. But in harsh environments, like chemical plants or high-heat furnaces, they might fail.

Expert Insight

“Ceramic fasteners are a game-changer for applications where metal simply can’t keep up,” says Dr. Emily Chen, a materials engineer. “Their ability to resist extreme conditions makes them worth the investment.” Learn more about material strengths at Eshino Precision’s material performance page.

Ceramic Screw for High-Heat Applications

Traditional Metal Screw

Types of Ceramic Fasteners Available

Ceramic fasteners come in many shapes and sizes to fit different needs. At Eshino Precision, we offer a wide range to help you find the perfect match for your project. Let’s look at the options.

Common Types of Ceramic Fasteners

Here are the main types you can choose from:

- Screws: Available in hex head, socket head, flat head, and Phillips head styles.

- Bolts: Includes hexagonal and socket cap bolts for strong connections.

- Nuts: Hex nuts and lock nuts to secure bolts.

- Washers: Flat and lock washers to distribute pressure.

- Threaded Rods: Long rods for custom-length applications.

- Set Screws: Small screws to hold parts without sticking out.

Check out our ceramic threaded parts for more details.

Standard and Custom Sizes

We offer standard sizes like M2 to M8 (metric) and 0-80 to 1/4-20 (imperial). Need something unique? Our custom ceramic parts can be tailored to your exact specifications. This flexibility makes ceramic fasteners ideal for specialized projects.

Why Variety Matters

Different jobs need different fasteners. For example, a flat head screw works well in tight spaces, while a hex bolt is great for heavy-duty tasks. Having options ensures you get the right fit for your mechanical engineering needs.

Materials Used in Ceramic Fasteners

The magic of ceramic fasteners lies in their materials. Each material has special powers that make it perfect for certain jobs. Let’s explore the main ones used at Eshino Precision.

Alumina (Al2O3): The All-Rounder

Alumina is super strong and affordable. It’s great for general use, like in electronics or chemical plants. It balances cost and performance, making it a popular choice.

Zirconia (ZrO2): The Tough One

Zirconia is extra tough and resists cracks. It’s perfect for high-stress environments, like automotive engines. Its durability makes it a top pick for demanding applications.

Silicon Carbide (SiC): The Wear Fighter

Silicon carbide is amazing for rough conditions. It handles wear and heat like a champ, ideal for oil and gas equipment. Its wear resistance ensures long-lasting performance.

Silicon Nitride (Si3N4): The Shock Absorber

Silicon nitride is strong and resists sudden temperature changes. It’s great for dynamic applications, like green energy systems. Its toughness makes it reliable under stress.

Choosing the Right Material

Picking the right material depends on your project. Need help deciding? Our guide on choosing technical ceramics can point you in the right direction.

Market Trends and Statistics for Ceramic Fasteners

The world of ceramic fasteners is growing fast, and it’s no surprise why! These tough little components are in high demand for high-tech industries. At Eshino Precision, we’re excited to be part of this booming market. Let’s look at the numbers and trends to see why ceramic fasteners are such a big deal.

How Big Is the Market?

The ceramic fasteners market is worth a lot of money, and it’s getting bigger every year. Here’s a simple table with the latest data:

| Year | Market Size (USD Billion) | Growth Rate (%) |

|---|---|---|

| 2024 | 2.5 | – |

| 2025 | 2.66 | 6.5 |

| 2033 | 4.1 | 6.5 |

This growth means more industries are choosing ceramic fasteners for their projects. By 2033, the market could be worth over $4 billion!

Why Is It Growing?

Several reasons are pushing this growth. First, industries like aerospace and automotive need lightweight, durable parts. Ceramic fasteners fit the bill perfectly. Second, electronics companies want non-conductive components for things like 5G devices. Third, green energy projects, like solar panels and wind turbines, rely on their durability.

“The demand for ceramic fasteners is skyrocketing as industries prioritize performance and sustainability,” says Dr. Emily Chen, a materials engineer at Advanced Ceramics Solutions.

Where Is the Market Strongest?

The Asia Pacific region, including China and India, leads the way because of huge production in electronics and construction. North America is also a big player, thanks to its focus on medical and aerospace innovations. At Eshino Precision, we serve customers worldwide, ensuring top-quality ceramic threaded parts for all these markets.

What’s Next for Ceramic Fasteners?

New technologies are making ceramic fasteners even better. For example, advances in ceramic CNC machining allow for more precise designs. This means more industries will use them in the future, from oil and gas to medical devices.

Frequently Asked Questions About Ceramic Fasteners

People have lots of questions about ceramic fasteners, and we’re here to answer them! These are the most common ones we hear at Eshino Precision. Let’s clear things up in a way that’s easy to understand.

What Are Ceramic Fasteners Made Of?

Ceramic fasteners are made from super-strong materials like alumina, zirconia, silicon carbide, and silicon nitride. These materials are tough and can handle extreme conditions without breaking.

Why Choose Ceramic Fasteners Over Metal Ones?

Ceramic fasteners are better for hot, corrosive, or electrical environments. They don’t melt, rust, or conduct electricity, unlike metal. For example, in electronics, they keep circuits safe. Metal fasteners are stronger for pulling forces but can’t handle extreme heat or chemicals as well.

Are Ceramic Fasteners Expensive?

Yes, ceramic fasteners cost more than metal ones because they’re harder to make. But they last longer in tough conditions, saving money on repairs. Think of them as a smart investment for projects like medical implants or aerospace engines.

Can They Handle High Heat?

Absolutely! Ceramic fasteners can work at temperatures up to 1500°C. That’s why they’re used in hot places like furnaces or car engines. Their high-temperature resistance is a big reason industries love them.

Are Ceramic Fasteners Brittle?

Yes, ceramic fasteners are more brittle than metal, so they need careful handling. You can’t twist them too hard, or they might crack. But with proper installation, they’re super reliable. Check our brittleness guide for tips.

Where Are They Used?

Ceramic fasteners are used in aerospace, medical, electronics, automotive, chemical processing, and green energy. They’re perfect wherever conditions are tough.

What Sizes Are Available?

We offer standard sizes like M2 to M8 (metric) and 0-80 to 1/4-20 (imperial). Need something special? Our custom ceramic parts can be made to fit your needs.

How Are They Installed?

Installing ceramic fasteners is similar to metal ones, but you need to be gentle. Use less force to avoid cracking them. Special tools can help, especially for mechanical engineering projects.

Conclusion

Ceramic fasteners are the heroes of tough environments, offering incredible heat resistance, corrosion protection, and electrical insulation. From aerospace engines to medical implants, they keep things safe and reliable. With a market growing to $2.66 billion in 2025, it’s clear these components are here to stay. At Eshino Precision, we’re proud to provide top-quality ceramic fasteners for your needs.

Learn More

Check out these resources for more information:

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.