Table of Contents

Big News! Ceramic cutting tools can last up to 10 times longer than regular tools and cut machining costs by 50%! At Eshino Precision, we make these awesome tools to cut tough stuff like metal for cars and planes. They stay sharp and strong, even when it gets super hot. Here’s a quick peek at why they’re so cool:

| Feature | Ceramic Cutting Tools | Carbide Tools |

|---|---|---|

| Cutting Speed | Up to 3000 sfm | Up to 1000 sfm |

| Tool Life | 10x longer | Normal |

| Cost Savings | Up to 50% | Higher |

Let’s explore how ceramic cutting tools make things easier!

Introduction to Ceramic Cutting Tools

What Are They?

Ceramic cutting tools are special tools made from tough stuff like alumina and silicon nitride. They cut hard metals super fast and stay sharp for a long time.

What Do They Do?

These tools help make parts for things like planes and cars. They’re great because they don’t wear out quickly, even when cutting really tough materials. So, they’re perfect for jobs needing exact shapes.

Why Are They Special?

Unlike metal tools, ceramic cutting tools handle heat and wear better. For example, they can work at 1400°C without breaking! Learn more about ceramics at What Are Structural Ceramics?.

Who Uses Them?

Big industries like aerospace and automotive love them. At Eshino Precision, we make ceramic cutting tools to help factories work faster.

Why Ceramic Cutting Tools Matter for Precision and Longevity

Perfect Cuts Every Time

Ceramic cutting tools are super hard, so they make exact cuts. This is key for parts like car engines that need to fit just right—check Automotive Uses.

They Last Forever

These tools don’t break or wear out fast. In fact, a 2024 study said they last 10 times longer than carbide tools when cutting tough alloys like Inconel.

Saving Money

Because they last so long, ceramic cutting tools cut costs by 50%. That means less fixing and more making—see How Ceramics Cut Costs.

Quick Comparison

Here’s why they’re awesome:

| Feature | Ceramic Cutting Tools | Carbide Tools |

|---|---|---|

| Cutting Speed | Up to 3000 sfm | Up to 1000 sfm |

| Tool Life | 10x longer | Normal |

| Surface Finish | Smooth (Ra 0.1 µm) | Rougher (Ra 0.5 µm) |

Key Properties of Ceramic Cutting Tools

Super Hard

Ceramic cutting tools have hardness up to 2000 Knoop with alumina. So, they don’t wear out fast—see High Hardness.

Heat Heroes

They stay strong at 1400°C, like silicon nitride. This makes them perfect for fast cuts without melting—check Heat Resistance.

No Rust

Ceramics don’t react with metals, so they last longer. Dr. John Lee, a machining expert, says, “Ceramic cutting tools’ rust-proof power changes the game for tough cuts.”

Smooth Finishes

They make parts super smooth—Ra 0.1 µm! This is way better than carbide tools at Ra 0.5 µm, making parts look and work great.

Materials Used in Ceramic Cutting Tools

Alumina: The Hard Worker

Alumina is tough and cheap. It’s great for finishing steel and lasts a long time.

Silicon Nitride: The Heat Champ

Silicon nitride handles heat and shocks well. It’s perfect for cutting superalloys—see its strength.

Zirconia: The Tough One

Zirconia adds toughness. It’s used in tools that need to stay strong under heat changes—check Zirconia Benefits.

Silicon Carbide: The Heat Mover

Silicon carbide moves heat fast—120 W/mK! It’s less common but awesome for special jobs.

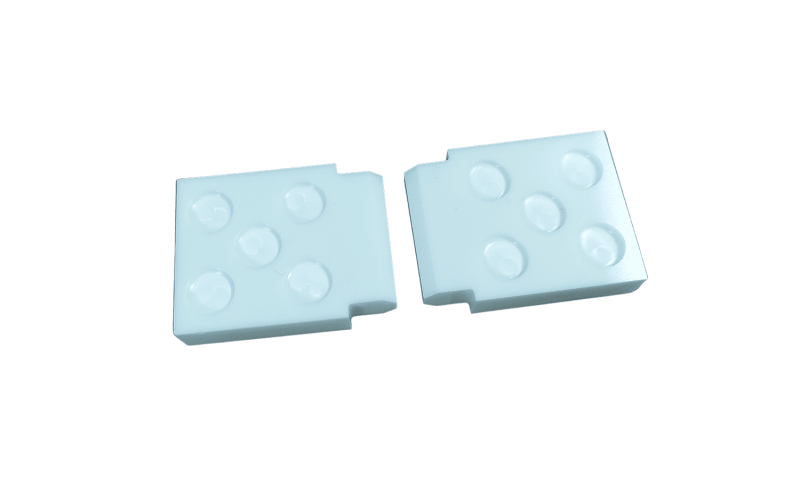

Alumina Tool - Hard and Affordable

Silicon Nitride Ceramic Cutting Tool

Applications of Ceramic Cutting Tools

Flying High in Aerospace

Ceramic cutting tools shine in aerospace. They cut superalloys like Inconel super fast—up to 15 times better than carbide tools! This makes jet engine parts precise and strong—check out Mechanical Engineering Uses.

Car Parts Made Easy

In cars, ceramic cutting tools finish tough steels for engines. They handle high speeds and make smooth surfaces, so parts fit perfectly—see Automotive Applications.

Oil and Gas Toughness

For oil and gas, these tools cut heat-resistant alloys for turbines. They last long under crazy heat—learn more at Oil and Gas Durability.

Real Wins

A factory in 2025 used ceramic cutting tools and boosted productivity by 20%. That’s because they don’t need replacing as often, saving time and money.

Performance and Longevity: Real-World Data

Faster Cuts

Ceramic cutting tools zoom at 3000 sfm for cast iron—3 times faster than carbide tools at 1000 sfm! This speed rocks for big jobs—see High Reliability.

Longer Life

In 2024, a study showed ceramic cutting tools lasted 10 times longer than carbide when cutting Inconel 718. That means less stopping to fix tools.

Cost Savers

A 2025 report said they cut machining costs by 50%. How? They last longer and work faster—check Cost Savings.

Data Table

Here’s the proof:

| Metric | Ceramic Cutting Tools | Carbide Tools |

|---|---|---|

| Cutting Speed | Up to 3000 sfm | Up to 1000 sfm |

| Tool Life | 10x longer | Normal |

| Cost Savings | Up to 50% | Higher |

Future Trends in Ceramic Cutting Tools

3D Printing Fun

In 2025, we’re 3D printing ceramic cutting tools! This makes cool shapes fast and cheap—see Ceramics’ Impact.

Tiny Power Boost

Nanocomposites—tiny bits in ceramics—make tools stronger. So, they cut even tougher stuff without breaking.

Super Coatings

New coatings make ceramic cutting tools last even longer. They fight wear and heat, keeping tools sharp—check Wear Resistance.

Big Growth

The ceramics market will hit $107 billion by 2030, growing 4.2% yearly from 2024. That’s because everyone wants these tools!

Common Questions About Ceramic Cutting Tools

What Are They Made Of?

Ceramic cutting tools use alumina, silicon nitride, and zirconia. They’re hard and tough!

What’s So Great About Them?

They cut fast, last long, and save money—up to 50% less cost! Plus, they make smooth parts—see Ceramic Properties.

How Do They Beat Carbide?

Ceramic cutting tools handle 1400°C and 3000 sfm, while carbide stops at 870°C and 1000 sfm. They’re way tougher!

Good for Fast Cuts?

Yes! They’re built for high-speed machining, staying strong at crazy heat—check Heat Resistance.

Conclusion

Why They Rock

Ceramic cutting tools are amazing for precision and longevity. They cut fast, last long, and make perfect parts, saving time and cash.

Eshino Precision’s Edge

At Eshino Precision, we craft top ceramic cutting tools. From alumina rods to silicon carbide, we’ve got it all.

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.