Technical ceramics find extensive applications in the chemical industry due to their exceptional properties such as high-temperature resistance, chemical inertness, wear resistance, and corrosion resistance.

Ceramic rods are distinguished by their high resistance to temperature, wear, and corrosion, along with excellent electrical insulation and mechanical strength, making them versatile for extreme conditions.

Ceramic disks are acclaimed for their excellent wear and corrosion resistance, high thermal stability, and superior electrical insulation, offering key advantages for high-performance applications.

Ceramic insulation blocks are highly valued for their exceptional thermal insulation properties, resistance to high temperatures, and stability in extreme environments, crucial for energy efficiency and safety in industrial applications.

Ceramic plungers are valued for their exceptional durability, high-temperature resistance, and excellent wear and corrosion resistance, making them ideal for demanding industrial applications.

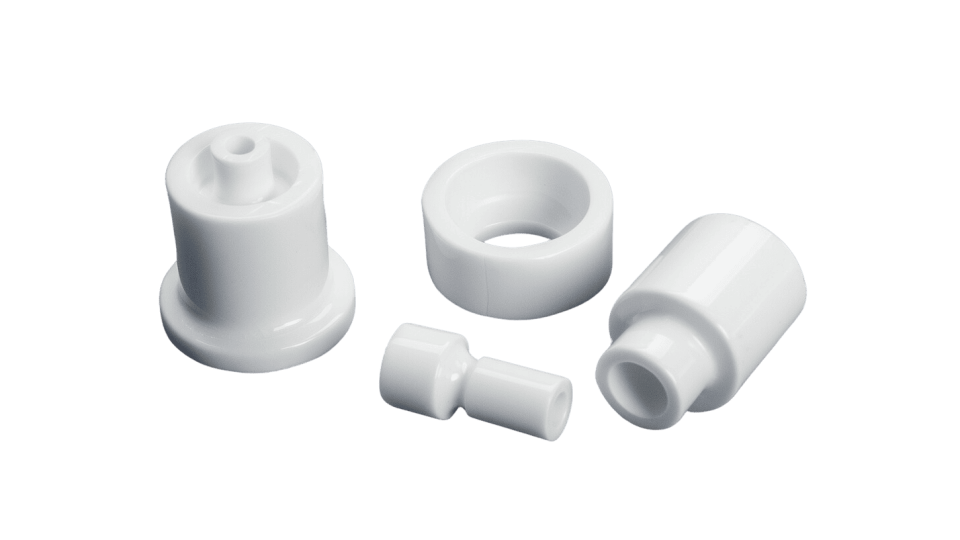

Ceramic bushings stand out for their superior wear and corrosion resistance, high-temperature tolerance, and excellent electrical insulation, making them highly effective in various mechanical and electrical applications.

Ceramic valves are recognized for their high wear and corrosion resistance, superior thermal stability, and excellent chemical inertness, making them ideal for controlling flow in harsh environments.

Ceramic welding rollers are highly appreciated for their exceptional wear resistance, ability to withstand high temperatures, and superior durability, ensuring consistent performance in demanding welding applications.

Ceramic pins are renowned for their exceptional wear resistance, high-temperature capabilities, and electrical insulation, making them suitable for precision applications across various industries.

Advanced ceramics play a pivotal role in the chemical industry, offering unique properties essential for a wide range of applications. These components are known for their exceptional chemical resistance, durability, and ability to withstand extreme conditions, making them indispensable in various chemical processes and equipment. Here are some detailed applications:

Chemical Processing Equipment

Catalyst Supports

Pumps and Valves

Membranes and Filters

Laboratory Equipment

Titanium Dioxide (TiO2)

Advanced ceramics are transforming the chemical industry by providing materials that offer unmatched chemical resistance, thermal stability, and mechanical strength. Understanding their properties and applications helps in selecting the right material for specific chemical processes, ensuring better performance, reliability, and efficiency

Industrial ceramic rods not only function in normal conditions but also excel in harsh environments characterized by high temperatures, high pressure, insulation requirements, and corrosive conditions. Using industrial ceramic rods ensures that instruments operate normally without suffering from fractures, wear, corrosion, or damage.

Withstands harsh chemicals and corrosive environments, ensuring longevity and reliability in chemical processes.

Maintains structural integrity at high temperatures, making them ideal for high-temperature applications.

High strength and hardness provide durability and resistance to wear and abrasion.

Reduces the risk of thermal shock, ensuring stability in fluctuating temperatures.

Fine porosity enables efficient filtration and separation processes.

Ceramics offer superior chemical resistance and can withstand high temperatures and corrosive environments better than metals, leading to longer lifespans and reduced maintenance costs.

Ceramic membranes provide fine porosity and high chemical stability, allowing for efficient filtration and separation of particles even in harsh chemical conditions.

Yes, many ceramic materials, such as silicon carbide and zirconia, have low thermal expansion and high thermal shock resistance, making them suitable for applications with rapid temperature fluctuations.

While ceramics have many advantages, they can be brittle and may require careful handling and design considerations to prevent fracture under extreme mechanical stress.

Ceramics like titanium dioxide and silicon carbide have high surface areas, excellent chemical resistance, and stability at high temperatures, enhancing the performance and longevity of catalysts in chemical reactions.

For any custom requests, talk with us now! We’re here 24/7/365, ensuring you get the best, always.

We will get back to you within 12 hours.

We will be in touch within 12 hours. Your intellectual property is 100% secure with us.