Table of Contents

Hey! Did you know ceramics in fluid handling can save you money and make stuff last longer? These tough parts, like pumps and valves, are superheroes for moving liquids and gases. First, check out this cool table with the top reasons they’re awesome:

| Awesome Feature | Why It Rocks |

| Corrosion Resistance | Handles acids and bases without rusting! |

| Wear Resistance | Lasts 50% longer than metal with rough stuff! |

| Heat Resistance | Works great up to 1600°C—super hot! |

| Keeps Fluids Clean | Doesn’t mix with liquids—perfect for food or medicine! |

| Saves Money | Cuts repair costs by up to 30%! |

Let’s dive into how ceramics in fluid handling help at Eshino Precision!

Introduction to Ceramic Parts in Fluid Handling

Ceramics in fluid handling are like magic helpers for moving liquids and gases. They’re tough parts made from special stuff like alumina or zirconia, used in things like pumps and valves. So, why are they cool? They don’t break down easy, even with nasty fluids or hot temperatures!

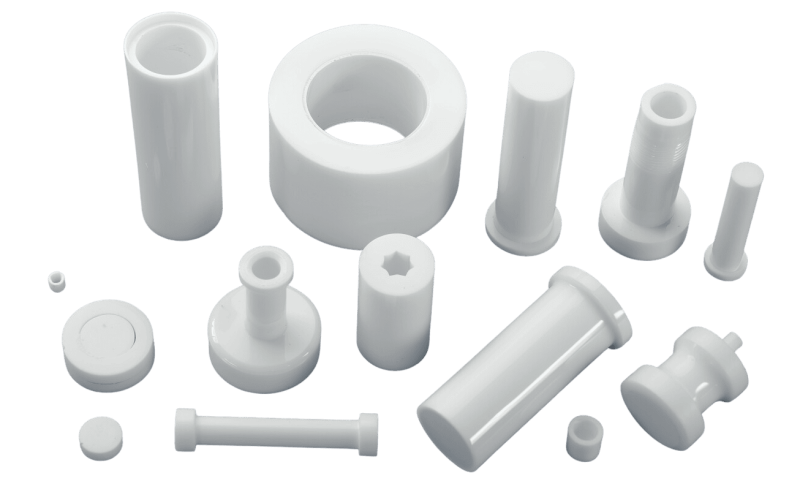

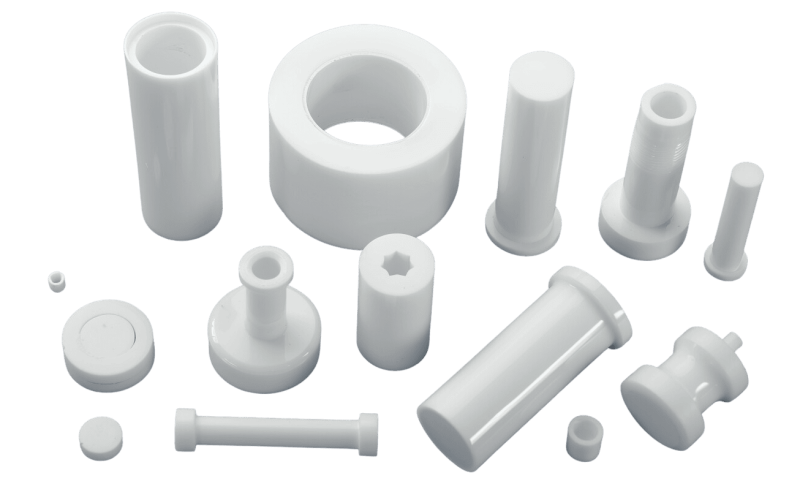

What Are Ceramic Parts?

First, imagine pumps and valves that don’t rust or wear out fast. That’s what ceramics in fluid handling do! They’re made from super strong materials, not like the clay pots you might think of. At Eshino Precision, we make them for tough jobs. Check out our ceramic valves or ceramic seals!

Plus, they’re perfect for places like chemical plants or water cleaners. Want to know more? Our blog, What Are Structural Ceramics?, explains it all!

Why Are They Important?

Next, think about saving money. Ceramics in fluid handling last way longer than metal—sometimes 50% more! Research says they can cut repair costs by 30% because they don’t break down in harsh stuff like acids. This makes them super important for big industries. At Eshino Precision, we love helping with that! See our chemicals page for how they work there.

Key Benefits of Ceramic Parts in Fluid Handling

Ceramics in fluid handling have some amazing powers! Here’s why they’re the best choice for pumps, valves, and more.

They Don’t Rust

First, ceramics in fluid handling don’t rust like metal. They can handle acids and bases without falling apart. This is huge for places like chemical plants! Our corrosion resistance page tells you more.

They Last Super Long

Then, they’re tough against wear. With rough fluids, ceramics in fluid handling can last 50% longer than metal parts. That means fewer fixes! Dr. Jane Smith, a ceramics expert, says, “Ceramics cut maintenance costs big time in tough spots!” Try our ceramic bushings to see!

They Love Heat

Also, ceramics in fluid handling stay strong in super hot places—up to 1600°C! This makes them perfect for hot liquids or gases. Check out our heat resistance page for the details!

Applications: Pumps, Valves, and More

Ceramics in fluid handling are used in tons of cool stuff! Let’s see where they help out.

Pumps That Keep Going

First, pumps use ceramics in fluid handling to move tricky liquids—like water with dirt in it. In water treatment, ceramic pump parts last 40% longer than metal ones. That’s less fixing! See how on our mechanical engineering page.

Valves That Stay Strong

Next, valves love ceramics in fluid handling too. In chemical plants, ceramic valve seats cut downtime by 25% because they don’t rust with acids. Our ceramic valves are built for that! Read more in Reducing Maintenance Costs.

Seals, Filters, and Sensors

Also, ceramics in fluid handling make awesome seals, filters, and sensors. Seals stop leaks in pumps, filters keep medicine clean, and sensors work in tough spots. Check out our ceramic seals or electronics page for more!

Types of Ceramic Materials Used in Fluid Handling

Ceramics in fluid handling come in different types, each with its own superpower. Let’s meet them!

Alumina: The Hard Worker

First, alumina is super hard—9 on the Mohs scale! It’s great for valve seats and seals because it doesn’t wear out fast. We use it a lot at Eshino Precision. So, for parts that need to last, alumina rocks! See our alumina page!

Zirconia: The Tough Guy

Then, zirconia is really strong—up to 1200 MPa! It’s perfect for pump parts that need to handle stress. Our zirconia ceramics are top-notch for that! Plus, it’s tough enough for rough jobs.

Silicon Carbide: The Heat Champ

Next, silicon carbide loves heat—up to 1600°C! It’s awesome for seals in hot fluid systems. Also, it’s super hard and fights wear like a champ. Check out our silicon carbide page to learn more!

Silicon Nitride: The All-Rounder

Finally, silicon nitride is a star too! It’s strong—600-900 MPa—and handles heat up to 1400°C. Plus, it’s great against wear, making it perfect for pumps or valves in hot, rough spots. We love it at Eshino Precision! See our silicon nitride page or blog about its strength!

Design Considerations for Ceramic Parts in Fluid Handling

Ceramics in fluid handling are awesome, but they need some smart planning to work their best. Here’s what we think about when making them!

Heat and Stretch

First, ceramics in fluid handling act different when hot. They don’t stretch like metal, so we design them carefully to avoid cracks. For example, alumina stays stiff while steel stretches more. Our materials performance page explains this!

Making Them Right

Next, ceramics are super hard to cut or shape. This makes them tricky to build, so we use special tools like lasers. It takes longer, but it’s worth it for tough parts like ceramic nozzles. Check out Precision Ceramic Components for more!

Keeping Them Sealed

Also, sealing ceramics in fluid handling can be tough. We use special tricks to stop leaks, like rubber rings or glue. This keeps pumps and valves working great, especially our ceramic seals!

Industrial Statistics and Market Trends (2025)

Ceramics in fluid handling are getting more popular every day! Let’s look at some big numbers for 2025.

How Much Are They Used?

First, the market for ceramics in fluid handling is $500 million in 2025! It’s growing by 6% every year until 2030. That’s because they’re so tough and save money. Chemical plants use them the most—35% of the total!

Where Are They Growing?

Next, water treatment loves ceramics in fluid handling the fastest. Rules are getting stricter, so they need parts that last. Here’s a table with the facts:

| Fact | Number |

|---|---|

| Market Size (2025) | $500 million |

| Growth Rate | 6% per year |

| Top User | Chemical Plants (35%) |

| Fastest Growth | Water Treatment |

Cool, right? See how ceramics help in oil and gas too!

Common Challenges and Solutions with Ceramic Parts in Fluid Handling

Ceramics in fluid handling are great, but they have some tricky bits. Here’s how we fix them!

They Cost More at First

First, ceramics in fluid handling cost 20-30% more than metal to start. But they save up to 30% on fixes later! So, they’re worth it over time. Our maintenance costs blog shows how!

They Can Break

Next, ceramics are strong but can crack if hit hard. We design them smart to avoid this, like making edges round. This helps parts like ceramic rods stay tough!

Hard to Shape

Also, shaping ceramics in fluid handling takes longer—up to 50% more time than metal. We use cool tools to make it work, ensuring parts like ceramic plungers are perfect!

Frequently Asked Questions (FAQs)

Got questions about ceramics in fluid handling? Here are some answers!

What Liquids Work Best?

First, ceramics in fluid handling love tough liquids like acids or gritty water. They don’t rust or wear out fast! They’re great for chemicals and water cleaning.

How Much Do They Cost Long-Term?

Next, they cost more at first—20-30% more than metal. But they save 30% on repairs later! Our blog, Reducing Maintenance Costs, explains this.

Do They Need Special Care?

Also, ceramics in fluid handling need less fixing than metal. Just check them for cracks now and then. This keeps ceramic valves happy!

Can They Handle Pressure?

Finally, yes! Ceramics like zirconia are super strong for high pressure. We design them right for oil and gas jobs!

Ceramics in fluid handling are the best for pumps, valves, and more! They fight rust, wear, and heat, plus they save money—up to 30% less on fixes. At Eshino Precision, we make them just for you, like ceramic seals or nozzles.

Ready to Transform Your Engineering Solutions?

Ready to try them? Contact Eshino Precision today for a free chat! See all our cool stuff on the product page and make your fluid handling awesome!