Table of Contents

Why Advanced Ceramic Technology Rocks

Advanced ceramics are like superhero materials! Here’s a quick look:

| Feature | Cool Fact |

|---|---|

| Super Strong | Handles tough jobs without breaking |

| Heat Proof | Stays cool up to 2400°C |

| Market Boom | $113.29B in 2024 to $250.30B by 2032 |

| Versatile | Used in cars, planes, and medical tools |

Introduction: What is Advanced Ceramic Technology?

What Are Advanced Ceramics?

Advanced ceramic technology is all about making super strong materials! These ceramics, like alumina and zirconia, are not like your grandma’s pottery. They’re built to handle tough stuff, like heat and heavy loads. At Eshino Precision, we use advanced ceramic technology to make parts for airplanes and medical devices.

How’s It Different?

Regular ceramics, like cups or tiles, break easily. But advanced ceramics are way tougher! They resist heat, wear, and even chemicals. This makes them perfect for electronics or cars. For example, they don’t melt in hot engines. Want to know more? Check our guide on traditional vs. advanced ceramics.

A Quick History

Advanced ceramic technology started getting big in the 1950s when planes and gadgets needed stronger materials. Now, with cool tricks like 3D printing, it’s growing fast! In fact, the market was $113.29 billion in 2024 and could hit $250.30 billion by 2032, says Fortune Business Insights. At Eshino Precision, we’re part of this exciting wave!

“Advanced ceramic technology is changing how we build tough machines,” says Dr. Jane Kim, a materials expert at TechCeram Labs.

Core Properties: Why Advanced Ceramics Stand Out

Super Strong and Tough

Advanced ceramics are like superheroes for strength! For example, alumina is super hard, up to 19 GPa, so it doesn’t wear out. Silicon nitride can handle heavy loads with a strength of 970 MPa. This makes them great for bearings and cutting tools that last forever!

Heat? No Sweat!

These ceramics love heat! Silicon carbide can take 1600°C, and zirconia even hits 2400°C. That’s why they’re used in hot engines or airplane parts. They also stay cool with great thermal conductivity, keeping machines safe.

Extra Cool Tricks

Advanced ceramics stop electricity, with alumina having resistivity over 10¹⁴ ohm-cm. This is awesome for electronic parts. Plus, they fight off acids and rust, perfect for chemical plants. Learn more about their strength and chemical resistance!

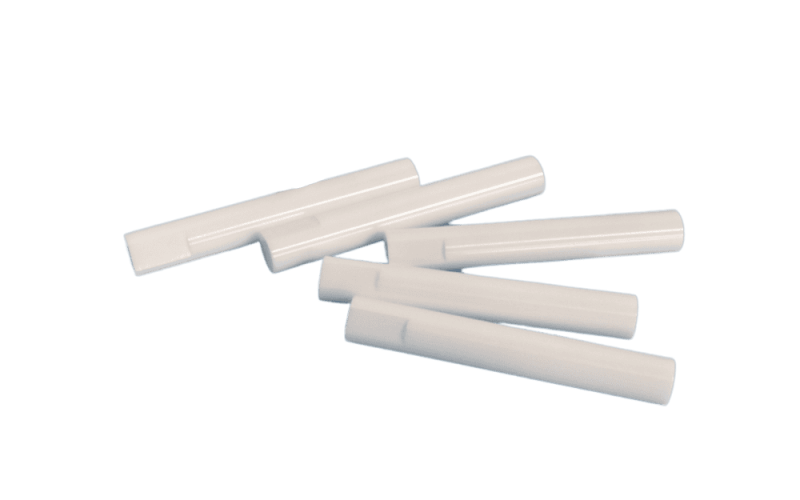

Alumina Rod for Tough Jobs

Silicon Nitride Bearing for Speed

Types of Advanced Ceramics: A Breakdown

Oxide Ceramics

Oxide ceramics, like alumina and zirconia, are super hard and tough. Alumina is great for seals because it doesn’t wear out. Zirconia is awesome for medical implants since it’s safe for your body. They’re both perfect for tough jobs!

Non-Oxide Ceramics

Non-oxide ceramics include silicon carbide and silicon nitride. Silicon carbide handles heat super well, up to 170 W/mK, great for engine parts. Silicon nitride is tough against shocks, ideal for bushings. These are stars in cars!

Composite Ceramics

Composite ceramics mix ceramics with other stuff to make them even better. For example, ceramic matrix composites are super strong for airplane parts. They’re light but tough, perfect for making planes fly better. Here’s a quick table:

| Type | Best Feature | Cool Use |

|---|---|---|

| Oxide | Hardness | Medical Implants |

| Non-Oxide | Heat Resistance | Engine Parts |

| Composite | Strength | Airplane Wings |

How They’re Made: The Manufacturing Process

Starting with Powder

Making advanced ceramics is like mixing a magic potion! First, we use super fine powders, like alumina or silicon nitride. These powders are carefully mixed to make sure the final parts, like rods or tubes, are strong. At Eshino Precision, we pick the best powders for top quality!

Shaping the Parts

Making Them Tough

Finishing Touches

Finally, we use fancy tools, like lasers or CNC machines, to make the parts super precise. This is important for things like electronic parts that need to be perfect. Our team at Eshino Precision is awesome at this, making sure every piece is ready for tough jobs! Learn more about ceramic machining.

Applications: Where Advanced Ceramics Shine

Airplanes and Defense

Advanced ceramic technology is a star in airplanes! Ceramics like silicon carbide make turbine blades that handle crazy heat. They’re also used in armor because they’re light but super strong. This helps planes fly better and stay safe!

Cars and Trucks

Electronics and Gadgets

Advanced ceramic technology keeps gadgets cool! Alumina is used in substrates to stop electricity and manage heat. This is super important for computer chips. Our ceramics make your devices work better!

Doctors and Dentists

Zirconia Pin for Precision

Alumina Substrate for Gadgets

Innovations: The Future of Advanced Ceramics

Tiny but Mighty Nanoceramics

Advanced ceramic technology is getting tiny with nanoceramics! These are ceramics with super small bits that make them extra strong. They’re great for medical tools because they’re tough and safe. At Eshino Precision, we’re excited to use these for seals!

3D Printing Magic

Now, we can 3D print ceramics! This lets us make super fancy shapes for airplanes or custom parts. It’s like building with digital clay! This makes advanced ceramic technology faster and more creative.

Smart and Healing Ceramics

Some ceramics are super smart! Piezoelectric ceramics make sensors that feel movement. Others can heal themselves, fixing tiny cracks. These are perfect for electronics and energy tech. We’re exploring these at Eshino Precision!

Better Medical Ceramics

Advanced ceramic technology is helping doctors, too. New coatings make implants fight germs better. This means safer surgeries and happier patients. Our team is working on these to make lives better!

“Innovations in advanced ceramics are opening new doors for engineering,” says Mark Lee, a ceramics specialist at Precision Tech Labs.

Market Insights: Trends and Growth

How Big Is the Market?

Advanced ceramic technology is booming! In 2024, the market for advanced ceramics was worth $113.29 billion. Experts say it could grow to $250.30 billion by 2032, with a 10.1% growth rate each year, according to Fortune Business Insights. That’s huge! It means more rods and seals for cool projects!

Why Is It Growing?

Lots of things are making advanced ceramic technology popular. For example, electronics need tough parts to keep gadgets working. Also, medical devices use ceramics for safe implants. Plus, electric cars love lightweight ceramics to go farther. At Eshino Precision, we’re ready for this growth!

Who’s Leading?

Asia-Pacific is the boss of advanced ceramics, with a 38% market share in 2023, says Precedence Research. Why? Because they make tons of electronics there! But, making these ceramics can be pricey, which is a challenge. Still, the future looks bright for advanced ceramic technology everywhere!

Market Snapshot

Here’s a quick look at the numbers:

| Year | Market Size (USD Billion) | Source |

|---|---|---|

| 2024 | 113.29 | Fortune Business Insights |

| 2023 | 107.00 | Grand View Research |

| 2032 | 250.30 | Fortune Business Insights |

Success Stories: Advanced Ceramics in Action

Airplanes Fly Better

Advanced ceramic technology makes airplanes awesome! For example, silicon carbide in jet engines cuts weight by 30%, says CeramTec. This saves fuel and makes planes faster. At Eshino Precision, we make tubes for these engines!

Healthy Smiles

Cool Gadgets

Advanced ceramic technology keeps electronics working! Alumina substrates handle heat in computer chips. This makes your phone or laptop last longer. Our substrates are perfect for this, says Mordor Intelligence.

Machine Power

In factories, advanced ceramics like silicon nitride make bushings and cutting tools. These parts don’t wear out, so machines run better. This saves money and time, and we’re proud to make them at Eshino Precision!

Challenges and What’s Next

Tricky Problems

Costs Can Be High

Cool Stuff Coming

The future of advanced ceramic technology is exciting! Scientists are making ceramics that fix themselves, like magic. Also, 3D printing is letting us create custom parts for planes. Plus, new medical ceramics will make implants even better. We’re ready at Eshino Precision!

“The next wave of ceramics will be smarter and tougher,” says Dr. Emily Chen, a researcher at Advanced Materials Lab.

FAQs: Your Questions Answered

What Are Advanced Ceramics?

Advanced ceramics are super tough materials, like alumina and zirconia, made for hard jobs. Unlike regular pottery, they’re built to handle heat, wear, and stress. At Eshino Precision, we use advanced ceramic technology to make parts for planes, cars, and medical tools. They’re like superheroes for machines!

What Are the Benefits?

Advanced ceramics are awesome because they’re super strong and don’t wear out. They can handle crazy heat, like 1600°C for silicon carbide. Plus, they stop electricity, which is great for electronic parts. They also fight rust, perfect for chemical plants. Check out our blog on ceramic benefits!

Where Are They Used?

Advanced ceramic technology is everywhere! You’ll find ceramics in airplane engines, car bearings, and dental implants. They’re also in gadgets to keep them cool and safe. Basically, anywhere that needs tough, long-lasting parts loves these ceramics!

How Big Is the Market?

The market for advanced ceramics is huge! It was $113.29 billion in 2024 and could hit $250.30 billion by 2032, growing 10.1% each year, says Fortune Business Insights. This growth means more seals and valves for awesome projects!

Why Choose Eshino Precision?

Our Ceramic Superpowers

Advanced ceramic technology is changing the world, and Eshino Precision is leading the way! We make super tough parts, like rods, tubes, and substrates. These ceramics handle heat, wear, and more, perfect for electronics, planes, and medical devices. Our work makes machines and people better!

Top Quality Every Time

At Eshino Precision, we use the best machines, like CNC, to make perfect parts. Whether it’s bushings for cars or seals for oil rigs, we meet tough standards. Our team checks every piece to ensure it’s awesome. Want to know how we do it? See our machining guide!

Let’s Build Together

Ready to make your projects tougher with advanced ceramic technology? Eshino Precision is here to help! Visit structuralceramic.com to explore our products or learn about choosing ceramics. Contact us today to start building something amazing with ceramics that last!

More Cool Resources

Want to learn more about advanced ceramic technology? Check these out:

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.