Table of Contents

Wow! Did you know ceramic pistons can handle heat hotter than a volcano and make cars go super fast? These amazing engine parts are changing how machines work! At Eshino Precision, we’re experts in ceramics, and we’re excited to tell you all about ceramic pistons!

| Feature | Why It’s Cool |

|---|---|

| Heat Power | Handles up to 1400°C! |

| Lightweight | Makes engines super speedy. |

| Uses | Race cars, food machines, and more! |

| Market | $2.87 billion in 2025! |

Introduction

What’s So Special?

Hey, ever wonder what makes race cars zoom so fast? It’s ceramic pistons! These are engine parts that can take crazy heat and make machines stronger. Unlike regular metal pistons, ceramic pistons are super tough and help engines work better. They’re used in cool places like fast cars and even airplanes.

Why They Matter

The market for ceramic pistons is growing fast. In 2025, it’s part of a $2.87 billion industry for car ceramics, and it’s getting bigger every year! At Eshino Precision, we make these parts to help engines run smoother and last longer.

What You’ll Learn

This guide will show you what ceramic pistons are, why they’re awesome, and where they’re used. Plus, we’ll share real examples and answer questions like, “Can I use them in my car?” Ready? Let’s dive in!

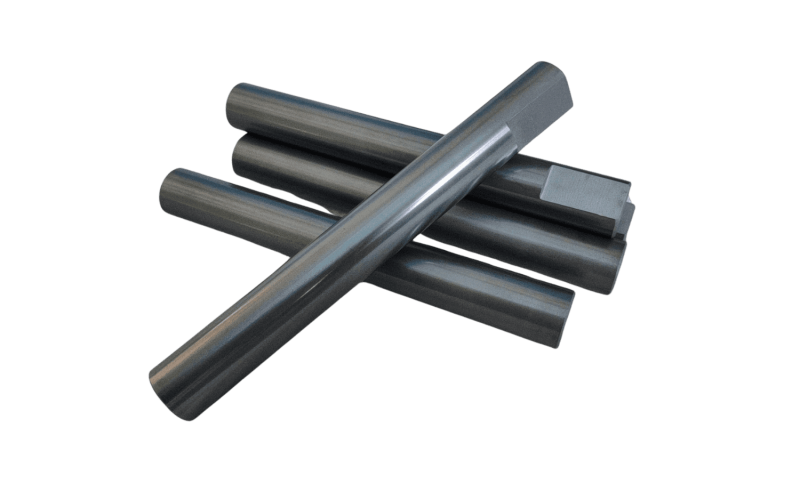

Silicon Nitride Rod: Tough for pistons!

Zirconia Rod: Heat-resistant!

What Are Ceramic Pistons?

The Basics

Ceramic pistons are like superheroes for engines! They’re parts that move inside engines to make cars or machines work. There are two kinds: fully ceramic pistons, which are made completely from ceramics like silicon nitride, and ceramic-coated pistons, which are metal with a ceramic layer on top.

Fully Ceramic vs. Coated

Fully ceramic pistons are rare and used in special engines, like in super-fast cars. They’re super light and handle extreme heat. Ceramic-coated pistons are more common, especially in race cars. The coating helps keep heat in the engine, making it stronger. At Eshino Precision, we work with both!

Why They’re Cool

Ceramic pistons are awesome because they make engines better. They’re used in tough places where metal pistons might break. Want to know more? Check out our guide on structural ceramics.

Advantages of Ceramic Pistons

Super Heat Power

First, ceramic pistons can handle crazy heat! Fully ceramic ones work at temperatures up to 1400°C or more, way hotter than metal pistons. This is perfect for high-heat engines. Ceramic-coated pistons trap heat, boosting power by up to 10%, says a study from SAE.

Light and Tough

Next, fully ceramic pistons are super light, so engines move faster. They’re also hard, so they don’t wear out easily. Ceramic-coated pistons reduce friction, saving fuel. Dr. Sarah Kim, an engine expert, says, “Ceramic pistons are game-changers for performance and durability in modern engines.” Learn more in our advantages guide.

Long-Lasting

Also, ceramic pistons don’t rust and last a long time. This saves money on repairs, as we explain in our cost-saving blog. Whether it’s a race car or a factory machine, these pistons keep going strong.

Applications of Ceramic Pistons

Zooming in Race Cars

Ceramic pistons shine in race cars! Ceramic-coated pistons are used in Formula 1 and drag racing because they make engines more powerful and last longer. Fully ceramic pistons are in super cars like the Chaos Ultracar, hitting speeds over 500 kph!

Heavy-Duty Engines

In diesel engines, ceramic pistons handle tough heat and pressure. They also make engines quieter and more efficient. Turbocharged engines love them too, as they stay strong under stress. Check out our car ceramics blog.

Other Cool Uses

Besides cars, ceramic pistons are used in airplanes and even food machines. In food processing, fully ceramic pistons are safe and durable for mixing stuff like milk or juice. Learn more about uses in our applications guide.

Materials Used in Ceramic Pistons

Super Strong Ceramics

Ceramic pistons are made from special materials that make them awesome! For fully ceramic pistons, we use stuff like silicon nitride. It’s super strong and handles high heat, perfect for car engines. Another one is zirconia, which is tough and great for extreme jobs.

Coating Magic

For ceramic-coated pistons, we put a thin layer of ceramics on metal pistons. A popular coating is yttria-stabilized zirconia, or YSZ. It acts like a heat shield, keeping the engine powerful. We also use alumina for some pistons because it’s hard and resists scratches. Learn more in our properties guide.

Why These Materials?

These materials make ceramic pistons super durable. They don’t wear out easily and can take tons of heat. At Eshino Precision, we pick the best ceramics for your needs. Here’s a quick look at them:

| Material | Superpower | Best For |

|---|---|---|

| Silicon Nitride | High heat strength | Car engines |

| Zirconia | Super tough | Extreme conditions |

| Alumina | Hard and insulating | Tools, coatings |

How Ceramic Pistons Are Made

Building Fully Ceramic Pistons

Making ceramic pistons is like crafting a superhero! For fully ceramic ones, we start with powders like silicon nitride. We shape them using cool tech like injection molding or 3D printing. Then, we bake them in a super hot oven called a kiln to make them rock-hard.

Adding Ceramic Coatings

For ceramic-coated pistons, we spray a thin layer of ceramics, like zirconia, onto metal pistons. After that, we heat or dry the coating so it sticks perfectly. This makes the piston stronger and better at handling heat. Check out our manufacturing guide.

Keeping It Perfect

At Eshino Precision, we check every step to make sure our ceramic pistons are top-notch. This is super important for parts like plungers or valves. Our CNC machining guide explains how we get it right.

Market Trends for Ceramic Pistons

Growing Fast

The market for ceramic pistons is zooming! In 2023, the automotive ceramics market was worth $2.6 billion, and by 2025, it’s expected to hit $2.87 billion. It’s growing 5% every year and could reach $4.1 billion by 2032, says IMARC Group. This is because cars need better engines!

Why It’s Happening

First, race cars and fast cars love ceramic pistons. Also, electric vehicles need strong parts, and ceramics are perfect. Plus, industries like automotive and green energy want parts that last longer. This makes ceramics a big deal!

Big Opportunities

This growth means more chances to use ceramic pistons. At Eshino Precision, we’re ready to help with parts like rods. Want to know more? Read our industry impact blog.

| Year | Market Size | Growth Rate |

|---|---|---|

| 2023 | $2.6 billion | – |

| 2025 | $2.87 billion | 5% |

| 2032 | $4.1 billion | 5% |

Real-World Examples of Ceramic Pistons

Super Fast Cars

Ceramic pistons are in the Chaos Ultracar! A company called XJET made a fully ceramic piston that helps this car go over 500 kph. That’s super fast! It shows how strong ceramics are in race cars.

Racing Power

In Formula 1, ceramic-coated pistons make engines last longer and run stronger. These coatings help cars zoom around tracks without breaking down. It’s like giving engines a superpower!

Everyday Machines

Also, ceramic pistons are used in food machines. Fully ceramic pistons mix things like milk or juice safely because they don’t rust. See more in our custom parts guide.

Maintenance and Care for Ceramic Pistons

Handle with Care

Fully ceramic pistons are tough but can crack if you drop them. So, be gentle when working with them! Also, check them often for any damage to keep engines running smoothly. Our durability guide has more tips.

Keep Coatings Happy

For ceramic-coated pistons, follow your engine’s care rules. Don’t push the engine too hard in ways that could peel the coating off. This keeps ceramic pistons working great for a long time.

Why It Matters

Good care means your ceramic pistons last longer and save money. At Eshino Precision, we design parts like plungers to be reliable. Check out our reliability blog.

The Future of Ceramic Pistons

Cool New Tech

The future of ceramic pistons is exciting! New 3D printing tech makes fully ceramic pistons easier to create. This means more cars and machines can use them. Learn about this in our tech blog.

Green Engines

Also, ceramic pistons are being tested in electric car motors and green engines. They help make cars faster and better for the planet. This is a big deal for green energy!

More Uses

Plus, ceramics might be used in new machines, like in factories. Their strength and long life make them perfect for the future. Read our future ceramics blog.

Conclusion

Why Ceramic Pistons Rock

Ceramic pistons are amazing! They handle super hot temperatures, make engines faster, and last a long time. From race cars to food machines, they’re changing how things work. With a market worth $2.87 billion in 2025, these pistons are the future!

Keep Exploring

Want more? Check out our blogs on piston benefits or custom parts. Let’s build something cool together!

References

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.