Table of Contents

Did you know the global alumina ceramic market is worth USD 3.6 billion in 2025 and will grow to USD 5.18 billion by 2033? That’s a 4.63% growth rate! At Eshino Precision, we’re experts in machining alumina ceramic to create parts for industries like electronics, aerospace, and medical. This guide explains what alumina ceramic is, how it’s machined, and why it’s so special. Let’s dive in!

| Metric | Value |

|---|---|

| Market Size (2025) | USD 3.6 billion |

| Projected Size (2033) | USD 5.18 billion |

| Growth Rate (CAGR) | 4.63% |

| Top Industries | Electronics, Aerospace, Medical |

Introduction to Alumina Ceramic

What Is Alumina Ceramic?

Alumina ceramic, also called aluminum oxide (Al₂O₃), is a super strong material made from bauxite, a type of rock. First, bauxite is processed to get alumina powder. Then, this powder is shaped and heated to make hard, durable parts. Because it’s tough, resists heat, and doesn’t conduct electricity, alumina ceramic is perfect for things like medical implants or electronic insulators. At Eshino Precision, we use it to make alumina ceramic rods and tubes for tough jobs.

Why Is It So Popular?

Alumina ceramic is a favorite in industries because it’s affordable and super reliable. For example, it can handle extreme heat (up to 1500°C!) and doesn’t wear out easily. Plus, the market for alumina ceramic is growing fast. In 2025, it’s worth USD 3.6 billion, and by 2033, it’ll hit USD 5.18 billion. That’s because industries like electronics and medical need strong parts. As Dr. Emily Chen, a ceramics expert, says:

“Alumina ceramic is the go-to material for precision parts because it balances cost, strength, and versatility like no other.”

At Eshino, we’re proud to help these industries with our alumina ceramic solutions.

How Does Eshino Precision Use It?

We specialize in machining alumina ceramic to make custom parts like seals and bushings. Our team uses advanced tools to shape this tough material into exactly what our clients need. Whether it’s for a spaceship or a hospital, we make sure every part is perfect. Want to learn more? Check out our guide to alumina ceramic rods.

Key Properties of Alumina Ceramic for Machining

Why Is Alumina So Hard?

Alumina ceramic is super hard, with a Vickers hardness of 18 GPa. That’s almost as tough as a diamond! This hardness makes it great for parts that need to last a long time, like ceramic nozzles. However, it also means machining alumina ceramic needs special tools, like diamond ones, because regular tools would break.

Other Cool Features

Besides being hard, alumina ceramic has other awesome traits that make it tricky but rewarding to machine:

- Brittleness: It can crack easily (fracture toughness of 4 MPa·m¹/²), so we must be super careful when cutting it.

- Heat Resistance: It can handle up to 1500°C for 99.9% pure alumina, perfect for hot environments like oil and gas equipment.

- Wear Resistance: Alumina doesn’t wear out quickly, which is great for parts but tough on our tools.

- Chemical Resistance: It doesn’t get damaged by most chemicals, so it’s safe to use with water or acids during machining.

These features make alumina ideal for wear-resistant ceramics, but they also mean we need smart machining tricks.

Comparing Alumina Types

Not all alumina is the same. Here’s a table comparing two common types we work with at Eshino Precision:

| Property | Al₂O₃ 99.5% | Al₂O₃ 99.9% |

|---|---|---|

| Hardness (GPa) | 18 | 18 |

| Fracture Toughness (MPa·m¹/²) | 4 | 4 |

| Max Temperature (°C) | 1,300 | 1,500 |

| Thermal Conductivity (W/(m·K)) | 30 | 33 |

Both types are tough, but 99.9% alumina can handle hotter conditions, which is why we use it for high-temperature ceramics.

How Is Alumina Ceramic Machined?

What Tools Do We Use?

Machining alumina ceramic isn’t like cutting wood or metal—it’s way harder! Because alumina is so tough, we use special methods to shape it. Here are the main ones we use at Eshino Precision:

- Diamond Grinding: We use wheels covered in tiny diamonds to grind alumina into smooth, precise shapes. This is great for parts like alumina ceramic tubes.

- Laser Machining: A laser beam cuts or carves alumina without touching it, perfect for tiny, detailed designs.

- Ultrasonic Machining: This uses fast vibrations and gritty particles to drill holes or shape parts without cracking them.

- Waterjet Cutting: High-pressure water mixed with sand cuts through thick alumina sheets, ideal for flat parts.

- Green Machining: We shape alumina before it’s fully hardened (when it’s “green”), then heat it to make it super strong. This saves our tools but needs careful planning.

Why These Methods Work

Each method is chosen based on what the part looks like and how precise it needs to be. For example, diamond grinding gives a super smooth finish for alumina ceramic seals, while lasers are best for tiny features. At Eshino, we pick the right method to make sure every part is perfect. Curious about machining other ceramics? Read our guide to silicon carbide machining.

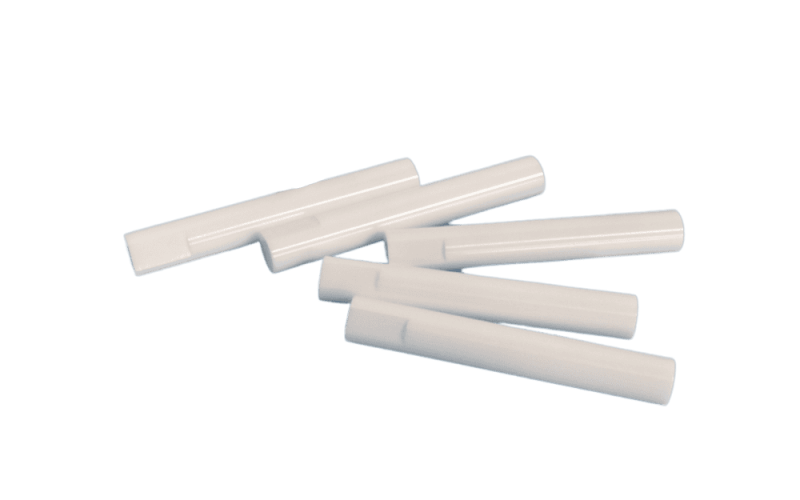

Product Spotlight: Alumina Ceramic Parts

Alumina Ceramic Rod

Tough and precise for industrial use.

Alumina Ceramic Tube

Heat-resistant for extreme conditions.

Challenges in Machining Alumina Ceramic

Why Is It So Tough to Machine?

Machining alumina ceramic is like trying to cut a super hard rock—it’s not easy! Alumina’s extreme hardness (Mohs 9) makes it resist regular tools, so we need special ones like diamond or cubic boron nitride (CBN). These tools are strong but expensive, which can make machining cost more. At Eshino Precision, we use these tools to create parts like alumina ceramic bushings that last a long time.

What Else Makes It Tricky?

Alumina ceramic has other challenges that make machining tough. Here’s a quick list of the biggest ones:

- Brittleness: Alumina can crack or chip easily because it’s not very flexible (fracture toughness of 4 MPa·m¹/²). We have to cut it gently to avoid breaks.

- Tool Wear: Alumina’s hardness wears out even our tough tools quickly, so we need to replace them often, which adds time and cost.

- Heat Buildup: Cutting alumina makes a lot of heat, which can cause cracks if we don’t cool it down with water or special liquids.

- Shrinkage in Green Machining: When we shape alumina before it’s fully hard (green state), it shrinks up to 20% when heated later. We must plan for this to get the right size.

These challenges are why machining alumina ceramic needs experts like us. Want to know more about tough ceramics? Check our guide to wear-resistant ceramics.

How Do We Solve These Problems?

At Eshino Precision, we’ve got tricks to handle these issues. For example, we use diamond-coated tools to cut through alumina’s hardness. We also add coolants to keep things from getting too hot, which prevents cracks. Plus, we adjust our machines to cut slowly and carefully, so the alumina doesn’t break. For green machining, we calculate the shrinkage ahead of time to make sure parts like alumina ceramic rods come out perfect. As industry expert Dr. John Lee says:

“Precision in machining alumina ceramic comes from understanding its limits and using the right tools and techniques to overcome them.”

Our solutions ensure high-quality parts for industries like medical and aerospace.

Applications of Machined Alumina Ceramic Components

Where Do We See Alumina Ceramic?

Machined alumina ceramic parts are everywhere in cool industries! Because alumina is so strong and can handle heat and wear, it’s used in lots of places. At Eshino Precision, we make parts for these industries, and they love how tough our alumina ceramic solutions are. Here’s where you’ll find them:

- Electronics: Alumina is used as insulators and substrates in devices like phones and computers because it doesn’t conduct electricity. Check our electronics guide.

- Mechanical: Parts like nozzles, valves, and bearings use alumina for its wear resistance.

- Medical: Alumina’s safe for the body, so it’s in implants, dental parts, and surgical tools. Learn more in our medical applications page.

- Aerospace: Alumina is in engine parts and sensors because it can take high heat and stay strong.

- Industrial: Tools, heat exchangers, and crucibles use alumina for its resistance to chemicals and heat.

Why Alumina Shines in These Uses

Alumina’s special features—like being hard, heat-resistant, and safe for medical use—make it perfect for these jobs. For example, in electronics, ceramic substrates keep devices working smoothly. In aerospace, alumina parts handle crazy temperatures in engines. At Eshino, we machine alumina to fit exactly what each industry needs, from seals to tubes.

Product Spotlight: More Alumina Parts

Alumina Ceramic Bushing

Durable for heavy-duty machines.

Alumina Ceramic Substrate

Perfect for electronics.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

New Advances in Machining Alumina Ceramic

What’s New in Machining?

Machining alumina ceramic is getting better thanks to new technology! At Eshino Precision, we stay on top of these changes to make better parts faster. One big advance is 3D printing. Instead of cutting alumina, we can now “print” complex shapes, which saves time and money. This is great for custom parts like custom ceramic components.

Other Cool Improvements

Here are some other new ways we’re making machining alumina ceramic easier:

- Better Diamond Tools: New diamond grinding tools last longer and cut smoother, giving parts like alumina ceramic rods a perfect finish.

- Advanced Lasers: New lasers cut with less heat, so we can make tiny, precise features without damaging the alumina.

- Hybrid Machining: Mixing techniques, like using lasers and grinding together, makes machining faster and less likely to crack the material.

These advances help us make parts for tough industries like semiconductors and oil and gas.

Why This Matters

These new methods mean we can make alumina parts quicker, cheaper, and with better quality. For example, 3D printing lets us create shapes that were too hard to machine before. As Dr. Sarah Kim, a machining expert, notes:

“Innovations like hybrid machining are revolutionizing how we work with alumina ceramic, making it more accessible for cutting-edge applications.”

At Eshino, we use these technologies to stay ahead and deliver top-notch parts. Learn more about ceramic manufacturing in our manufacturing guide.

Frequently Asked Questions (FAQs)

What Methods Are Used for Machining Alumina Ceramic?

Machining alumina ceramic uses special techniques because it’s so hard. The main methods are:

- Diamond grinding for smooth, precise shapes.

- Laser machining for tiny, detailed cuts.

- Ultrasonic machining for drilling without cracks.

- Waterjet cutting for thick pieces.

- Green machining for shaping before hardening.

At Eshino, we choose the best method for parts like alumina ceramic tubes. See our CNC machining guide for more.

What Are the Challenges in Machining Alumina Ceramic?

The biggest challenges are alumina’s hardness, brittleness, tool wear, and heat buildup. It’s super hard (Mohs 9), so only diamond tools work well. It can crack easily, wears out tools fast, and gets hot when cut. We solve these with careful cutting, coolants, and strong tools, ensuring parts like alumina ceramic seals are perfect.

Can Alumina Ceramic Be Machined with Conventional Tools?

No, regular tools like carbide can’t handle fully hardened alumina ceramic because it’s too hard (Mohs 9). We use diamond tools for the best results. However, in the “green” state (before hardening), softer tools can work if we’re careful. This is why Eshino uses advanced tools for high-hardness ceramics.

Does Purity Affect Machinability?

Alumina’s purity (like 99.5% or 99.9%) doesn’t change its machinability much because the hardness (18 GPa) stays the same. Higher purity might handle heat better, but it doesn’t make machining easier or harder. We account for this when making alumina ceramic rods.

Conclusion

Machining alumina ceramic is a tough but amazing process that creates super strong parts for industries like electronics, aerospace, and medical. At Eshino Precision, we use special tools and new technologies to shape alumina into parts like tubes, seals, and bushings. With the alumina market growing from USD 3.6 billion in 2025 to USD 5.18 billion by 2033, there’s never been a better time to explore this material.

Ready to see how alumina ceramic can help your projects? Contact Eshino Precision today or visit our alumina ceramic solutions page to learn more. Let’s build something tough together!

External Resources

- High Alumina Ceramic Market Report – Market size and growth data.

- Top Seiko: Alumina Properties – Technical details on alumina.

- UNIPRETEC: Alumina Machining – Insights on machining techniques.

- ScienceDirect: Ceramic 3D Printing – Advances in ceramic manufacturing.

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.