Table of Contents

Quick Facts About Alumina Ceramic Rods

| Feature | Details |

|---|---|

| Material | High-purity aluminum oxide (96%–99.8% Al₂O₃) |

| Key Properties | Hardness, thermal stability (up to 1,800°C), electrical insulation |

| Applications | Electronics, aerospace, medical, semiconductors |

| Market Growth | USD 2.32B (2024) to USD 3.5B (2032), 5.25% CAGR |

Introduction

Why Alumina Ceramic Rods Matter

Imagine a material so tough it can handle blazing heat, resist harsh chemicals, and insulate electricity like a champ. That’s what alumina ceramic rods do! Made from high-purity aluminum oxide, these rods are superstars in industries like electronics, aerospace, and manufacturing. At Eshino Precision, we’re seeing more engineers and manufacturers turn to these rods for their projects. Why? Because they’re reliable and built to last in tough conditions. This guide explains everything you need to know about alumina ceramic rods, from their properties to their real-world uses.

What You’ll Learn

In this article, we’ll break down the science behind alumina ceramic rods, show you where they’re used, and help you pick the right one for your needs. Plus, we’ll share cool facts, like how the market for these rods is growing fast—expected to hit USD 3.5 billion by 2032! Whether you’re designing a new machine or upgrading equipment, this guide is your go-to resource. Let’s dive in!

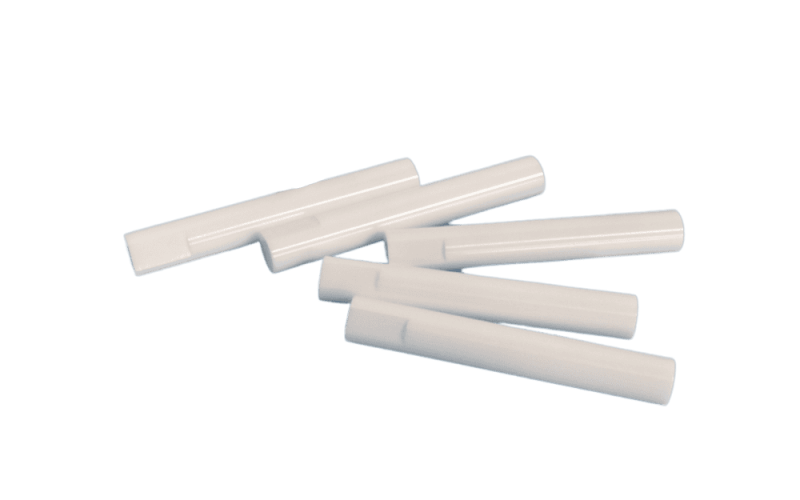

High-purity alumina ceramic rod for industrial use

Alumina rod in semiconductor equipment

What are Alumina Ceramic Rods?

The Basics of Alumina Ceramic Rods

Alumina ceramic rods are solid, stick-shaped pieces made from aluminum oxide, or Al₂O₃. This material is super pure, often between 96% and 99.8%, which makes it incredibly strong. These rods are designed to handle tough jobs, like working in super-hot furnaces or resisting wear in heavy machinery. Because they’re so durable, industries rely on them for projects where failure isn’t an option. At Eshino Precision, we craft these rods to meet exact specifications for your equipment.

Why They’re Special

What makes alumina ceramic rods stand out? For starters, they’re harder than most metals and can take a beating without breaking. They also stay strong in crazy-high temperatures—up to 1,800°C! Plus, they don’t conduct electricity, so they’re perfect for insulating parts in electronics. According to industry expert Dr. Jane Lin, a materials scientist, “Alumina ceramic rods are a game-changer because they combine strength, heat resistance, and insulation in one material.” That’s why they’re a top choice for advanced manufacturing.

Properties of Alumina Ceramic Rods

Key Features That Make Them Awesome

Alumina ceramic rods have some amazing qualities that make them perfect for tough jobs. Here’s what they can do:

- Super Hard: They’re almost as hard as diamonds, so they don’t wear out easily.

- Heat-Proof: They can handle temperatures up to 1,800°C without melting or cracking.

- Great Insulators: They block electricity, making them ideal for high-voltage machines.

- Chemical-Proof: Acids and other harsh chemicals can’t damage them.

- Stable Shape: They don’t expand or shrink much when heated or cooled.

These properties make alumina ceramic rods a go-to for industries needing reliable parts. Learn more about material strengths at Eshino’s high-strength ceramics page.

Technical Specs in a Nutshell

Here’s a quick look at the numbers behind alumina ceramic rods. This table shows how two common types, AL97 and AL98, compare:

| Property | AL97 | AL98 |

|---|---|---|

| Al₂O₃ Content | 97% | 99.80% |

| Tensile Strength | 30 Kpsi | 32 Kpsi |

| Hardness | 13.8 HV, GPa | 18 HV, GPa |

| Thermal Conductivity | 25 W/(m K) | 32 W/(m K) |

| Working Temperature | 1500 °C | 1750 °C |

For a deeper dive, check out our alumina ceramic materials page.

Applications of Alumina Ceramic Rods

Where You’ll Find These Rods

Alumina ceramic rods are used in all kinds of cool places because they’re so tough. For example, in semiconductor manufacturing, they help make computer chips by holding up in super-precise machines. In electronics, they act as insulators to keep circuits safe. They’re also found in aerospace, where they handle the heat in jet engines, and in medical devices, where they’re used in implants because they’re safe for the body. These rods are like the unsung heroes of modern tech!

Real-World Examples

Here’s a quick rundown of where alumina ceramic rods shine:

- Chip-Making Machines: Used in tools for creating tiny circuits.

- High-Heat Furnaces: Keep things stable in super-hot environments.

- Wear-Resistant Parts: Act as bearings or nozzles in heavy machines.

- Medical Tools: Safe for surgical implants and devices.

Want to see how ceramics fit into electronics? Visit our blog on ceramics in the electronics industry.

Advantages of Using Alumina Ceramic Rods

Why Choose Alumina Ceramic Rods?

Alumina ceramic rods are like superheroes for industrial parts because they have so many awesome benefits. First, they’re amazing at blocking electricity, which makes them perfect for machines that use high voltage. They also last a long time in places with harsh chemicals, like acids or alkalis, so your equipment stays in great shape. Plus, these rods can handle super-hot temperatures—up to 1,800°C—without breaking or melting. This makes them a top pick for tough jobs in industries like aerospace and electronics. At Eshino Precision, we see these rods helping our customers save money by lasting longer than other materials.

More Cool Benefits

Another big win is that alumina ceramic rods don’t wear out easily. They’re so hard that they can take a lot of rubbing and scraping without getting damaged. They also stay the same shape even when things get really hot or cold, which prevents cracks or warping. Oh, and they’re safe for medical use because they don’t react with the body or release harmful stuff. Dr. Maria Chen, a ceramics engineer, says, “Alumina ceramic rods are a top choice for engineers because they combine durability with safety, making them ideal for everything from medical implants to heavy machinery.” Check out how ceramics reduce wear in our blog on wear-resistant ceramics.

How to Choose the Right Alumina Ceramic Rod for Your Application

Finding the Perfect Fit

Picking the right alumina ceramic rod is like choosing the best tool for a job—it needs to match your project perfectly. Start by looking at the purity level. Rods with higher purity, like 99.8% alumina, are better for jobs needing strong insulation or super-high heat resistance, such as in electronics. Next, think about size. The rod’s length and diameter should fit your machine’s design exactly. At Eshino Precision, we can customize rods to your exact measurements, so you get the perfect fit.

Other Things to Consider

You’ll also want to check the rod’s strength and hardness. If your machine deals with a lot of rubbing or heavy loads, pick a rod with high compressive strength. For hot environments, make sure the rod can handle the maximum temperature of your setup. Don’t forget about cost—higher-purity rods might cost more, but they could save you money in the long run by lasting longer. Not sure where to start? Our team at Eshino Precision can help you find the right rod for your project. Learn more about choosing materials in our guide on selecting technical ceramics.

Manufacturing Process of Alumina Ceramic Rods

How These Rods Are Made

Making alumina ceramic rods is like baking a super-strong cake—it takes careful steps to get it just right. First, we start with high-purity alumina powder, which is ground up and mixed with special ingredients called binders to make a smooth, goopy mixture. This mixture is then shaped into rods using methods like extrusion (think squeezing toothpaste) or pressing. At Eshino Precision, we use advanced techniques to ensure every rod is perfectly formed for your needs.

Finishing the Process

Next, the rods are dried to get rid of water and pre-heated to burn off the binders, which helps avoid cracks. Then, they’re fired in a super-hot oven—up to 1,600°C—to make them super strong and dense. Sometimes, we use a special method called hot isostatic pressing to make them even tougher. Finally, the rods are polished and ground with diamond tools to get the exact size and smooth surface you need. This careful process ensures our rods meet the highest standards. Want to know more about ceramic manufacturing? Check out our blog on ceramic CNC machining.

Comparison with Other Ceramic Materials

Alumina vs. Other Ceramics

Alumina ceramic rods are awesome, but how do they stack up against other materials like zirconia and silicon carbide? Each has its own superpowers, so let’s compare them to see which is best for your project. Alumina ceramic rods are super cost-effective and great at blocking electricity, making them perfect for things like electronics. However, zirconia is tougher and better for medical uses, while silicon carbide is the hardest and loves extreme heat. At Eshino Precision, we help you pick the right material for your needs.

Breaking Down the Differences

Here’s a simple table to show how these materials compare:

| Property | Alumina (Al₂O₃) | Zirconia (ZrO₂) | Silicon Carbide (SiC) |

|---|---|---|---|

| Hardness (HV10, MPa) | 1400 – 1800 | 1200 – 1300 | 2500 |

| Thermal Conductivity (W/mK) | 25 – 30 | 2 | 75 |

| Max Operating Temp (°C) | 1500 – 1750 | 900 – 950 | 1500 – 1800 |

| Flexural Strength (MPa) | 290 – 340 | 500 – 1100 | 420 |

Alumina is a budget-friendly choice with great insulation, but it’s not as tough as zirconia. Silicon carbide is super hard and great for heat, but it’s pricier. Want to learn more? Check out our blog on zirconia vs. alumina. Dr. Emily Wong, a ceramics expert, says, “Alumina ceramic rods are often the best balance of cost and performance for industrial applications.”

Recent Advancements in Alumina Ceramic Technology

New Tricks for Alumina Ceramic Rods

In 2025, alumina ceramic rods are getting even cooler thanks to new technology. One big change is 3D printing, which lets us make rods in all kinds of shapes without wasting material. This is super helpful for custom parts in industries like semiconductors. Another upgrade is ultra-high-purity alumina, which makes rods 50% better at resisting wear. These improvements mean your equipment lasts longer and works better. At Eshino Precision, we’re using these new methods to create top-notch rods for you.

Exciting Uses in Medicine

Alumina ceramic rods are also making waves in medical devices. Scientists are mixing alumina with zirconia to make super-strong parts for dental implants and surgical tools. These new materials are made using a cool process called digital light processing, which shapes them with light! This makes them perfect for precise, safe medical work. Want to know more about ceramic innovations? Read our blog on the evolution of advanced ceramics.

Market Trends and Statistics for Alumina Ceramic Rods

Why the Market is Growing

The market for alumina ceramic rods is booming! In 2024, it was worth USD 2.32 billion, and experts say it’ll grow to USD 3.5 billion by 2032. That’s a growth rate of 5.25% every year! Why? Because industries like automotive, aerospace, and electronics are using more of these rods. For example, car makers use them in sensors, and aerospace companies need them for jet engine parts. This growth shows how important alumina ceramic rods are becoming.

Numbers to Know

Here’s a quick look at the market’s future:

| Year | Market Size (USD Billion) |

|---|---|

| 2024 | 2.32 |

| 2032 | 3.50 |

These numbers prove alumina ceramic rods are a hot item. To see how ceramics are changing industries, visit our blog on the impact of advanced ceramics.

Case Studies and Examples of Alumina Ceramic Rods in Use

Real-World Success Stories

Alumina ceramic rods are like the secret sauce in many industries, making machines work better and last longer. In the semiconductor industry, these rods are used in machines that make computer chips. They handle super-precise tasks, like moving delicate silicon wafers, without breaking or wearing out. This keeps production smooth and saves companies time and money. At Eshino Precision, we’ve seen our alumina ceramic rods shine in cleanroom environments where precision is everything. Check out how ceramics boost high-tech manufacturing in our blog on precision ceramic components.

More Cool Uses

In the automotive world, alumina ceramic rods are found in sensors and engine parts. They can handle the heat and vibrations of a car engine, making vehicles more reliable. For example, they’re used in oxygen sensors that help cars run cleaner. In aerospace, these rods are part of jet engine turbines, where they stay strong under extreme heat. Dr. Robert Hayes, an aerospace engineer, says, “Alumina ceramic rods are critical for lightweight, heat-resistant components in modern turbines.” These examples show why alumina ceramic rods are so popular. Learn more about ceramics in cars at our automotive ceramics blog.

People Also Ask: Common Questions About Alumina Ceramic Rods

What Are Alumina Ceramic Rods Used For?

Alumina ceramic rods are super versatile! They’re used in electrical insulation for high-voltage machines, semiconductor manufacturing for making computer chips, and high-temperature furnaces to handle crazy heat. They also work as wear-resistant parts in heavy machines and even in medical devices like implants because they’re safe for the body. Their strength and durability make them a go-to choice for tough jobs. See how ceramics are used across industries in our blog on advanced ceramics applications.

How Are Alumina Ceramic Rods Made?

Making alumina ceramic rods is a careful process. First, we take high-purity alumina powder and mix it with binders to create a smooth mixture. Then, we shape it into rods using techniques like extrusion or pressing. After that, the rods are dried and heated to remove binders, then fired at 1,600°C to make them super strong. Finally, they’re polished to get the perfect size and smoothness. This ensures top quality for your projects. Learn more about ceramic production in our guide on ceramic CNC machining.

Where Can I Buy Alumina Ceramic Rods?

You can get high-quality alumina ceramic rods from trusted suppliers like Eshino Precision. We offer rods in different sizes and purities to fit your needs. Other reliable sources include Advanced Ceramic Materials and Precision Ceramics, but make sure the supplier can provide the exact purity and dimensions you need. At Eshino, we customize rods to match your project perfectly. Contact us at structuralceramic.com to get started!

Conclusion

Why Alumina Ceramic Rods Are the Future

Alumina ceramic rods are game-changers for industries needing tough, reliable parts. With their super hardness, ability to handle extreme heat, and excellent insulation, they’re perfect for everything from computer chips to jet engines. The market is growing fast—expected to hit USD 3.5 billion by 2032—showing just how important these rods are. Whether you’re in semiconductors, automotive, or medical, alumina ceramic rods can make your equipment better and longer-lasting.

External Resources

Ready to Transform Your Engineering Solutions?

Ready to power up your projects with alumina ceramic rods? At Eshino Precision, we’re here to help you find the perfect rods for your needs. Our team can customize sizes, purities, and shapes to fit your machines exactly. Don’t wait—contact us today to get a quote or learn more about our alumina ceramic solutions. Let’s build something amazing together!