Table of Contents

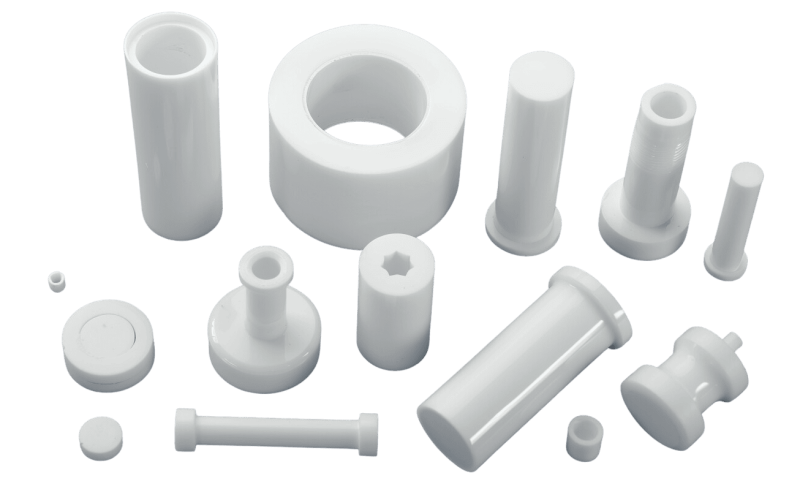

Did you know that zirconia sleeves are the tiny heroes behind fast, reliable internet connections? These small ceramic components are key to keeping data flowing smoothly in fiber optic systems. At Eshino Precision, we’re experts in crafting high-performance zirconia ceramics for industries like telecommunications. In this guide, we’ll explain what zirconia sleeves are, why they’re awesome, and how to pick the right ones for your needs. Let’s dive in with a quick look at what makes them special!

| Fact | Detail |

|---|---|

| Material | Zirconium oxide (ZrO2) |

| Main Job | Aligning ferrules in fiber optics |

| Top Benefits | Precision, durability, low signal loss |

| Market Size (2025) | $250 million, growing 8% yearly |

Introduction to Zirconia Sleeves

What Are Zirconia Sleeves?

Zirconia sleeves are small, super-precise parts made from a strong ceramic called zirconium oxide, or ZrO2. In fiber optic systems, they act like tiny tunnels that hold and align the ends of cables (called ferrules) so data signals can pass through clearly. Imagine them as the perfect matchmakers for internet cables, ensuring no signal gets lost! Because of their role, zirconia sleeves are a big deal in places like data centers and telecom networks. At Eshino Precision, we make these sleeves to help keep your connections fast and reliable.

Why Are They Important?

Without zirconia sleeves, your internet could slow down or even stop. They keep signals strong, which is super important for things like video calls, streaming, and 5G networks. Plus, zirconia is tough and lasts a long time, so these sleeves don’t wear out easily. According to industry expert Dr. Jane Lin, a materials scientist, “Zirconia sleeves are critical for high-speed networks because their precision reduces signal loss better than any other material.” This makes them perfect for modern tech, and we’re proud to craft them at Eshino Precision!

How Do They Fit in Fiber Optics?

In fiber optics, zirconia sleeves are used in connectors like SC, LC, and FC, which are found in everything from your home router to huge data centers. They’re small but mighty, ensuring cables stay perfectly aligned. Want to learn more about how ceramics power industries? Check out our blog on structural ceramics to see why materials like zirconia are game-changers.

Zirconia Sleeve for Fiber Optics

High-Precision Zirconia Ceramic

Why Zirconia Sleeves Are Valuable

Super Precise for Perfect Connections

Zirconia sleeves are made with incredible accuracy, down to super tiny measurements (called sub-micron tolerances). This means they align cable ends perfectly, so data moves without any hiccups. For example, in a data center, even a tiny misalignment could slow down your Netflix stream! Our zirconia ceramics are crafted to ensure this never happens, keeping signals clear and fast.

Tough and Long-Lasting

Unlike some materials, zirconia is super strong and doesn’t wear out, even after thousands of connections. It’s like a superhero that never gets tired! This durability saves money because you don’t need to replace parts often. Curious about how zirconia boosts durability? Read our blog on zirconia’s wear resistance for more details.

Low Signal Loss and More Perks

Zirconia sleeves keep signal loss super low, which is key for fast internet. They also handle tough conditions like heat or dampness without breaking down. Compared to other materials like phosphor bronze, zirconia is way better for high-performance needs. As Dr. Lin notes, “Zirconia’s stability in extreme environments makes it the go-to choice for reliable fiber optics.” These qualities make zirconia sleeves a top pick for engineers and businesses.

Types of Zirconia Sleeves: Split vs. Solid

Split Sleeves: Flexible and Reliable

Split zirconia sleeves have a small cut along their side, making them slightly flexible. This helps them hold two cable ends (ferrules) tightly in adapters, like those used in SC or LC connectors. They’re great for telecom because they can handle slight size differences in cables. At Eshino Precision, our split sleeves are made to fit perfectly, ensuring strong connections every time.

Solid Sleeves: Extra Precise

Solid zirconia sleeves, also called precision sleeves, are super exact and used in things like optical transceivers (devices that send and receive data). They need to be perfect because even a tiny mistake could mess up the signal. These sleeves are trickier to make, but we nail it with our advanced zirconia technology.

Which Type Should You Choose?

Here’s a quick comparison to help you decide:

- Split Sleeves: Best for adapters in connectors like SC, LC, or FC. They’re flexible and widely used in telecom.

- Solid Sleeves: Perfect for optical modules where super precision is needed, like in transceivers.

| Feature | Split Sleeves | Solid Sleeves |

|---|---|---|

| Use | Aligning ferrules in adapters | Connecting optical modules |

| Precision | High | Very high |

| Applications | SC, LC, FC connectors | Transceivers, PD modules |

Need help picking the right sleeve? Our team at Eshino Precision can guide you!

Applications in Fiber Optic Connectors

SC Connectors: Easy and Reliable

SC (Subscriber Connector) connectors are popular in telecom because they’re easy to plug in and out with a push-pull design. Zirconia sleeves inside SC connectors keep cables aligned for clear signals. They’re used in things like phone networks and internet hubs, where reliability is key.

LC Connectors: Small but Mighty

LC (Lucent Connector) connectors are tiny, making them perfect for crowded data centers. Zirconia sleeves ensure these small connectors still deliver big performance, keeping data moving fast. Our ceramic components are designed to meet these high demands.

FC and ST Connectors: Specialized Uses

FC (Ferrule Connector) connectors are used in testing equipment because they’re super secure with a screw-on design. ST (Straight Tip) connectors, with their bayonet style, are common in military and networking setups. Both rely on zirconia sleeves for precision and durability, ensuring they work in tough conditions.

How Zirconia Sleeves Are Made

Starting with Pure Zirconia

Making zirconia sleeves begins with super pure zirconium oxide powder, also called ZrO2. This powder is created using special methods like heating or chemical processes to make it super fine and uniform. Why does this matter? Because pure, even powder makes stronger, more reliable sleeves. At Eshino Precision, we use only the best materials to ensure our zirconia ceramics meet top standards.

Shaping the Sleeves

Next, the powder is shaped into tiny tubes using techniques like extrusion or injection molding. Think of it like squeezing dough through a cookie cutter, but way more precise! These methods create the rough shape of the zirconia sleeves. We carefully control this step to make sure every sleeve starts off just right. Want to know more about ceramic shaping? Check out our blog on custom ceramic parts.

Polishing for Perfection

After shaping, the sleeves are machined and polished with super accurate tools. This step makes the inside and outside super smooth and exact, down to tiny measurements. It’s like sanding a piece of wood until it’s perfectly smooth, but for high-tech ceramics. According to industry expert Dr. Mark Chen, “The precision in machining zirconia sleeves is what sets them apart, ensuring flawless performance in fiber optics.” Our team at Eshino Precision uses advanced tech to get this step perfect.

Checking Every Detail

Finally, every zirconia sleeve is tested to make sure it’s perfect. We check things like how round it is, how strong it holds cables, and how smooth its surface is. These tests follow strict rules from groups like the International Electrotechnical Commission (IEC). This ensures our sleeves work great in real-world uses, like telecom networks or data centers.

Market Trends and Insights

Growing Demand for Zirconia Sleeves

The world loves fast internet, and that’s great news for zirconia sleeves! In 2025, the market for these sleeves in fiber optics is worth about $250 million, and it’s growing by 8% every year. By 2033, it could reach $463 million! Why? Because things like 5G networks and bigger data centers need more reliable parts. Our zirconia technology is ready to meet this demand.

Why the Market Is Booming

The rise of 5G and high-speed internet is pushing companies to use better components like zirconia sleeves. These sleeves are key in fiber optic adapters and transceivers, which are used everywhere from phone towers to cloud storage. The Asia Pacific region, especially, is a big market because of its huge tech industry. This growth means businesses need trusted suppliers like Eshino Precision.

Market Forecast

Here’s a quick look at where the zirconia sleeve market is headed:

| Year | Market Size (USD Million) | CAGR (%) |

|---|---|---|

| 2025 | 250 | – |

| 2033 | 463 | 8 |

This table shows why investing in high-quality zirconia sleeves now is a smart move for future-ready businesses.

How to Choose the Right Zirconia Sleeve

Match the Connector Type

First, make sure the zirconia sleeve fits your connector, like SC, LC, or FC. Each connector has specific needs, and the sleeve must match perfectly. For example, LC connectors need smaller sleeves for tight spaces in data centers. Not sure which connector you’re using? Our team at Eshino Precision can help you figure it out!

Think About Your Application

Next, consider what you’re using the sleeve for. If it’s for an adapter (like in telecom), go for a split sleeve. If it’s for something super precise, like an optical transceiver, choose a solid sleeve. Knowing your application helps you pick the best sleeve. Learn more about precision ceramics in our blog on high-tech manufacturing.

Check Performance Needs

Look at things like how much signal loss you can handle and how durable the sleeve needs to be. Zirconia sleeves are great for low signal loss and long life, but you should still check the specs. For tough conditions, like hot or wet environments, zirconia’s strength shines. Dr. Chen adds, “Choosing the right sleeve means balancing precision with environmental demands, and zirconia excels here.”

Partner with Experts

Picking the right zirconia sleeve can feel tricky, but you don’t have to do it alone. At Eshino Precision, we make high-quality sleeves tailored to your needs. Our ceramic components are built to last, and we’re here to guide you every step of the way.

Frequently Asked Questions (FAQs)

What Are the Benefits of Using Zirconia Sleeves in Fiber Optics?

Zirconia sleeves are awesome because they align cables perfectly, keep signal loss low, and last a long time. They also handle heat and moisture well, making them great for telecom and data centers. These benefits make them better than other materials for fast, reliable connections.

How Do Zirconia Sleeves Compare to Other Materials?

Compared to phosphor bronze, zirconia sleeves are more precise and durable. Phosphor bronze is cheaper but can’t match zirconia’s performance in high-speed or singlemode systems. For more on ceramic advantages, see our blog on zirconia vs. alumina.

What’s the Difference Between Split and Solid Zirconia Sleeves?

Split sleeves are flexible and used in adapters to connect two cables. Solid sleeves are super precise and used in devices like transceivers. Each has its own job, so choosing depends on your setup.

Why Is Zirconia Used in Fiber Optics?

Zirconia is strong, resists wear, and can be made super precise. This makes it perfect for keeping fiber optic connections clear and reliable, especially in tough conditions.

How Are Zirconia Sleeves Manufactured?

They’re made by shaping pure zirconia powder, machining it for precision, and testing it to meet strict standards. It’s a careful process to ensure every sleeve is perfect.

Are There Industry Standards for Zirconia Sleeves?

Yes! Groups like the IEC set rules for size, strength, and performance to make sure zirconia sleeves work well in all kinds of fiber optic systems.

Conclusion

Why Zirconia Sleeves Matter

Zirconia sleeves are tiny but powerful, keeping our internet and telecom systems running smoothly. With their precision, durability, and low signal loss, they’re a must-have for modern tech. Whether you’re building 5G networks or data centers, these sleeves make a big difference. At Eshino Precision, we’re proud to craft top-quality zirconia sleeves for your needs.

External Resources

- Senko: Zirconia Sleeves Overview – Learn more about zirconia sleeves in fiber optics.

- Kyocera: Ceramic Sleeves – Explore how ceramics are used in connectors.

- Lily Bearing: Ceramic Ferrules and Sleeves – A guide to ceramic components in telecom.

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.