Table of Contents

Key Takeaways: Why Low Thermal Conductivity Ceramics Matter

| What Are They? | Special materials like zirconia and fused silica that block heat. |

|---|---|

| Why Important? | They protect machines and save energy in super-hot places. |

| Where Used? | Jet engines, furnaces, and kilns for insulation. |

| How Do They Work? | Tiny holes or unique structures trap heat to keep it from spreading. |

| Market Growth | Worth $5.01 billion in 2023, growing to $9.19 billion by 2030. |

Quick Fact: Low thermal conductivity ceramics are like superheroes for keeping heat where it belongs! For example, they help jet engines stay safe while saving fuel. Next, let’s dive into what makes these ceramics so cool (or rather, not hot!).

Why Start Here?

First, this table gives you the big picture about low thermal conductivity ceramics. Moreover, it’s perfect for anyone curious about how these materials work. So, whether you’re a student or a business owner, you’ll find this info super helpful. Additionally, at Eshino Precision, we’re experts in making these ceramics for tough jobs.

What’s Coming Up?

Next, we’ll explain what these ceramics are in a way anyone can understand. Then, we’ll explore why they’re so important and where they’re used. Also, we’ll share fun examples and even a quote from an expert! Ready? Let’s go!

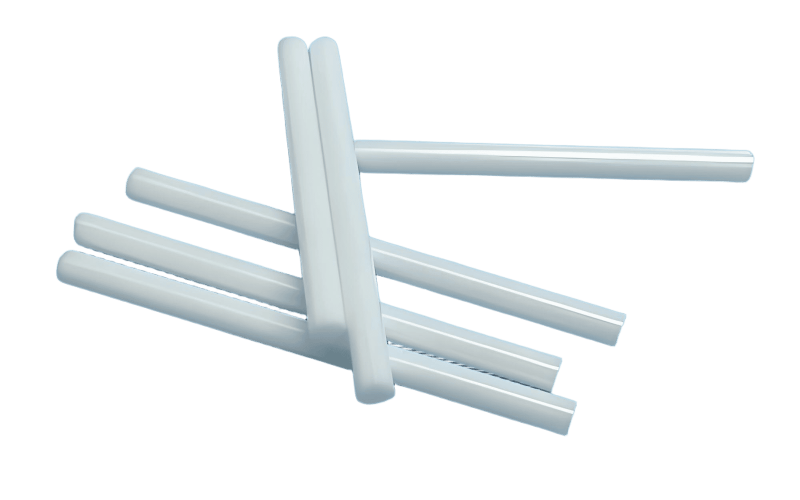

Zirconia Rod for High-Heat Insulation

Ceramic Tube for Furnace Linings

Introduction: What Are Low Thermal Conductivity Ceramics?

Imagine holding a hot cocoa mug that doesn’t burn your hands. That’s what low thermal conductivity ceramics do for machines! Basically, these are special materials that stop heat from moving through them. For instance, they keep jet engines from getting too hot or help furnaces save energy. At Eshino Precision, we make these ceramics to handle super-hot jobs.

How Do They Work?

First, low thermal conductivity ceramics have tiny holes or special structures. Consequently, these features trap heat, so it doesn’t spread. For example, materials like zirconia and fused silica are great at this. Also, their thermal conductivity is usually below 5 W/mK, which means they’re awesome at blocking heat. In fact, this makes them perfect for tough places like factories or planes.

Why Should You Care?

Next, these ceramics save energy and protect equipment. Moreover, they’re used in industries you might not think about, like making steel or glass. So, understanding them can help you see how modern machines stay safe and efficient. Plus, as our materials page explains, these ceramics are key for high-heat challenges.

A Fun Fact to Start

Did you know low thermal conductivity ceramics can handle temperatures over 2400°C? That’s hotter than lava! Therefore, they’re like heat shields for machines. Now, let’s see why these ceramics are such a big deal in the next section.

“Low thermal conductivity ceramics are game-changers for energy efficiency,” says Dr. Jane Carter, a materials scientist at Morgan Advanced Materials. “They allow industries to push performance limits while cutting costs.”

Why Are These Ceramics Important?

Low thermal conductivity ceramics are like superheroes for machines that work in super-hot places. Specifically, they stop heat from escaping or damaging parts. As a result, they save energy and make equipment last longer. At Eshino Precision, we use these ceramics to help industries like aerospace and steel-making. So, let’s break down why they’re so important.

Saving Energy

First, these ceramics keep heat where it’s needed. For example, in a furnace, they stop heat from leaking out. Consequently, this saves fuel and lowers energy bills. In fact, industries using ceramic tubes can cut energy use significantly. Also, this helps the planet by reducing waste.

Protecting Equipment

Next, low thermal conductivity ceramics act like shields. For instance, they protect jet engine parts from melting under extreme heat. Moreover, this means machines can work harder without breaking. As our high-temperature resistance page shows, these ceramics are tough enough for the hottest jobs.

Helping Industries Grow

Additionally, these ceramics are key for big industries. Specifically, they’re used in making steel, glass, and even electricity. Therefore, they help companies make better products faster. Plus, with zirconia ceramics, businesses can rely on strong, heat-blocking materials. In short, these ceramics make modern life possible!

Where Are They Used?

Low thermal conductivity ceramics are everywhere in industries that deal with heat. Basically, they’re used to keep things safe and efficient in super-hot places. For example, they’re in planes, factories, and even glass-making plants. At Eshino Precision, we supply these ceramics for all kinds of cool uses. So, let’s check out where they shine!

Jet Engines in Aerospace

First, these ceramics are used in jet engines. Specifically, zirconia coatings protect turbine blades from crazy heat. As a result, engines can run hotter, which saves fuel. For instance, planes like the Boeing 787 use these coatings to fly better. Also, this makes flying safer and cheaper.

Furnaces in Steel and Glass

Next, low thermal conductivity ceramics line furnaces. For example, ceramic tubes keep heat inside, so steel or glass can be made efficiently. Consequently, this saves energy and cuts costs. Moreover, these ceramics can handle temperatures up to 1400°C, as our chemicals application page explains.

Kilns for Ceramics and More

Finally, these ceramics are used in kilns. Specifically, they line the walls to trap heat, which helps make tiles or glass. Therefore, kilns work better and use less energy. Plus, ceramic plates from Eshino Precision are perfect for these high-heat jobs. In short, low thermal conductivity ceramics make industries stronger!

Types of Low Thermal Conductivity Ceramics

Low thermal conductivity ceramics come in different types, and each one has a special job. Basically, they’re like a team of superheroes, each with its own power to block heat. For example, some are super strong, while others handle sudden heat changes. At Eshino Precision, we make these ceramics for all kinds of industries. So, let’s meet the main types!

Zirconia: The Tough Guy

First, zirconia is super strong and blocks heat well. Specifically, it has a thermal conductivity of 1.7–2.7 W/mK, which means it’s great at stopping heat. For instance, it’s used in jet engines and ceramic seals to keep things safe. Also, zirconia is tough enough to handle rough jobs, as explained on our zirconia benefits page.

Fused Silica: The Heat-Shock Star

Next, fused silica is amazing at handling sudden heat changes. With a thermal conductivity of 1.38 W/mK, it’s perfect for glass-making or semiconductor equipment. Moreover, it doesn’t crack easily, which makes it super reliable. For example, ceramic tubes made from fused silica keep heat in check.

Cordierite and Others

Additionally, cordierite is great because it doesn’t expand much when heated. With a thermal conductivity of 1.3–1.7 W/mK, it’s used in car parts like catalytic converters. Also, materials like mullite and ceramic fiber blankets are awesome for furnaces. Specifically, ceramic fiber blankets have ultra-low conductivity (0.035–0.052 W/mK), as noted on our materials page. In short, each type has a unique role!

Zirconia Seal for Heat Insulation

Ceramic Plate for Kiln Linings

What Makes These Ceramics Good at Blocking Heat?

Low thermal conductivity ceramics are like magic shields that stop heat from moving. But how do they do it? Basically, their special features make them great at trapping heat. For example, tiny holes or unique designs block heat flow. At Eshino Precision, we know how to make these ceramics extra effective. So, let’s explore what makes them so good!

Tiny Holes Trap Heat

First, many ceramics have tiny holes, or porosity. These holes trap air, which slows down heat. For instance, ceramic tubes with lots of holes are super insulators. Consequently, this makes them perfect for furnaces, as explained on our low thermal conductivity page. Also, more holes mean better heat-blocking power.

Special Structures Stop Heat

Next, the way a ceramic’s bits are arranged matters. Specifically, some structures, like in zirconia, scatter heat waves. As a result, heat can’t move easily. For example, zirconia’s unique crystal setup makes it a top choice for jet engines. Moreover, this is why zirconia vs. alumina is a big debate for engineers.

Heat Changes Things

Finally, heat itself can make these ceramics better. In fact, many get better at blocking heat when they’re super hot. For instance, materials like mullite work great in kilns because of this. Therefore, they’re ideal for tough jobs, as shown on our chemicals application page. In short, these features make low thermal conductivity ceramics unbeatable!

“Porosity and crystal structure are key to low thermal conductivity,” says Dr. Mark Thompson, a ceramics expert at Unifrax. “These properties make ceramics essential for high-heat industries.”

How Are They Made?

Making low thermal conductivity ceramics is like baking a super-strong cake! Specifically, it takes special ingredients and careful steps to get them just right. For example, some ceramics are made dense, while others have holes to trap heat. At Eshino Precision, we’re experts at crafting these ceramics for tough jobs. So, let’s see how they’re made!

Making Dense Ceramics

First, dense ceramics like zirconia are shaped and heated. Basically, we mix powders, form them into shapes like zirconia rods, and bake them at high temperatures. As a result, they become super strong and heat-resistant. Also, this process, called sintering, is key for parts in jet engines, as noted on our mechanical engineering page.

Adding Holes for Extra Insulation

Next, some ceramics are made with holes to block heat better. For instance, we add bubbles or special ingredients that burn away, leaving tiny holes. Consequently, this makes ceramic tubes great insulators. Moreover, these porous ceramics are used in furnaces, as explained on our petrochemical page.

Spinning Ceramic Fibers

Finally, ceramic fiber blankets are made by spinning fibers like yarn. Specifically, these fibers are woven into soft, heat-blocking blankets. For example, they’re used in steel mills to trap heat. Therefore, they’re super effective, with conductivity as low as 0.035 W/mK. Plus, our materials page shows how Eshino Precision perfects these processes.

How Do They Compare to Other Materials?

Low thermal conductivity ceramics are awesome, but how do they stack up against other heat-blockers? Basically, they’re stronger and tougher than many alternatives. For example, they beat materials like fiberglass or foam in high-heat jobs. At Eshino Precision, we know ceramics are the best choice for tough tasks. So, let’s compare them!

Comparing Heat Blocking

First, here’s a table to show how they compare:

| Material | Heat Blocking (W/mK) | Max Heat (°C) | Strength |

|---|---|---|---|

| Zirconia | 1.7–2.7 | 2400 | High |

| Ceramic Blanket | 0.035–0.052 | 1400 | Low |

| Fiberglass | 0.04 | 500 | Low |

Clearly, ceramics like zirconia are champs at handling high heat.

Strength and Toughness

Next, ceramics are way stronger than alternatives like aerogels or foam. For instance, zirconia rods can hold up under pressure, unlike soft insulators. Consequently, they’re perfect for mechanical engineering tasks. Also, our advantages page explains why ceramics win.

Where They Shine

Finally, ceramics work in harsh places where others fail. For example, they resist chemicals and heat better than fiberglass. Therefore, they’re ideal for chemical plants. In short, low thermal conductivity ceramics are the go-to for tough, hot jobs!

What’s New in This Field?

Low thermal conductivity ceramics are getting even better, thanks to new discoveries! Specifically, scientists are finding ways to make them block heat even more. For example, they’re using tiny structures and new materials to push the limits. At Eshino Precision, we stay on top of these trends to bring you the best ceramics. So, let’s check out what’s new!

Tiny Structures for Big Results

First, researchers are using nanotechnology to create super-tiny structures. For instance, carbon-ceramic nonwovens have “sea-island” designs that block heat like never before. In fact, they can have a thermal conductivity as low as 19.8–31.8 mW/mK! Consequently, these are great for energy-saving devices, as noted on our new energy page. Also, this tech could make ceramic substrates even better.

New Materials on the Scene

Next, new ceramics like lanthanum zirconate are making waves. Specifically, these have lots of tiny holes, which makes them amazing insulators. For example, they’re used in super-hot places like jet engines. Moreover, they’re tougher than older ceramics, as explained on our high-strength ceramics page. Therefore, they’re perfect for cutting-edge industries.

Smarter Manufacturing

Finally, new ways to make ceramics are saving money and time. For instance, low-temperature sintering and replica methods create strong, heat-blocking parts faster. As a result, companies can use zirconia rods and other ceramics more easily. Plus, our evolution of ceramics page shows how these advances build on old ideas. In short, the future of low thermal conductivity ceramics is super exciting!

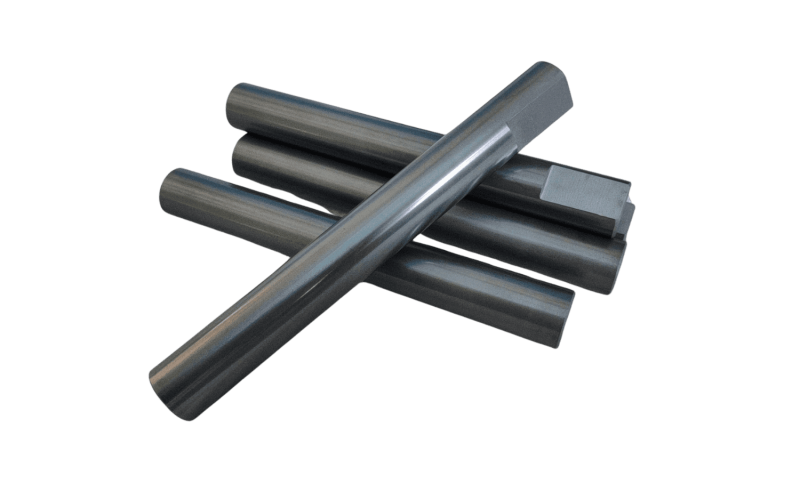

Silicon Nitride Rod for Insulation

Ceramic Disc for High-Heat Applications

The Growing Market for These Ceramics

The world loves low thermal conductivity ceramics, and the market is growing fast! Specifically, more industries want these ceramics to save energy and follow tough rules. For example, they’re in high demand for planes, factories, and power plants. At Eshino Precision, we’re ready to meet this demand with top-quality ceramics. So, let’s look at the numbers!

Big Money, Big Growth

First, the thermal ceramics market was worth $5.01 billion in 2023. Moreover, experts say it’ll hit $9.19 billion by 2030, growing at 9.05% each year. Consequently, this shows how much industries need ceramics like zirconia. Also, our advanced ceramics impact page explains why this growth matters.

Why the Boom?

Next, strict rules about emissions are pushing companies to use better insulators. For instance, ceramics help factories use less fuel, which cuts pollution. Additionally, industries like steel, glass, and aerospace need tough materials like ceramic tubes. Therefore, the demand keeps rising, as noted on our oil and gas page.

Who’s Leading?

Finally, big companies like Morgan Advanced Materials and Unifrax are top players. However, Eshino Precision stands out with custom solutions. For example, our ceramic plates are perfect for high-heat jobs. In short, the market for low thermal conductivity ceramics is hot, and we’re leading the charge!

“The thermal ceramics market is booming due to energy efficiency demands,” says Dr. Sarah Lee, a materials engineer at Isolite Insulating Products. “Ceramics are the future of insulation.”

Real-World Examples

Low thermal conductivity ceramics are hard at work in real life, making things better! Specifically, they’re used in cool places like jet engines and steel mills. For example, they save energy and keep machines safe. At Eshino Precision, we’re proud to supply ceramics for these awesome jobs. So, let’s see some examples!

Jet Engines Fly Higher

First, zirconia coatings are used in jet engines. For instance, planes like the Boeing 787 use these coatings to protect turbine blades from heat. As a result, engines can run hotter, which saves fuel and boosts power. Moreover, our automotives page shows how ceramics help vehicles perform better.

Steel Mills Save Energy

Next, ceramic fiber blankets line furnaces in steel mills. Specifically, they trap heat, so less energy is wasted. For example, this helps mills make steel faster and cheaper. Consequently, companies save money, as explained on our maintenance costs page. Also, our ceramic plates are great for these furnaces.

Glass-Making Gets Better

Finally, fused silica lines kilns for making glass. For instance, it keeps heat inside, so kilns use less energy. Therefore, glass products are made more efficiently. Plus, our chemicals page highlights how ceramics shine in tough industries. In short, low thermal conductivity ceramics make the world work better!

Quick Answers to Your Questions

Got questions about low thermal conductivity ceramics? Don’t worry, we’ve got answers! Specifically, we’ll tackle the top questions people ask. For example, we’ll cover what they’re used for and how they work. At Eshino Precision, we love sharing this info. So, here are quick answers!

What Are They Used For?

First, low thermal conductivity ceramics keep heat in place. For instance, they’re used in jet engines, furnace linings, and kiln walls. As a result, they save energy and protect parts. Moreover, our applications page lists tons of uses for these ceramics.

How’s Heat Blocking Measured?

Next, scientists use a laser to test how fast heat moves through ceramics. Specifically, this “laser flash method” measures thermal conductivity. For example, zirconia scores low, which means it’s great at blocking heat. Also, our materials page explains this in detail.

What Helps Them Block Heat?

Finally, tiny holes and special structures stop heat. For instance, more holes mean better insulation, like in ceramic tubes. Additionally, the way crystals are arranged helps, too. Therefore, these ceramics are perfect for hot jobs, as shown on our zirconia guide.

Conclusion: Why Choose Eshino Precision?

Low thermal conductivity ceramics are superstars for keeping heat in check! Specifically, they protect machines, save energy, and make industries like aerospace and steel-making better. For example, materials like zirconia and fused silica handle crazy heat while staying strong. Moreover, the market for these ceramics is growing fast, hitting $9.19 billion by 2030. At Eshino Precision, we’re experts at making these ceramics for tough jobs.

Your Next Step

Now advanced ceramic components can transform your business. So, why not explore our ceramic products? For instance, our zirconia rods and ceramic tubes are perfect for high-heat challenges. Also, check out our materials page to learn more.

External Resources

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.