Table of Contents

Introduction: Why Technical Ceramics Are a Big Deal in 2025

Did you know the technical ceramics market will hit $10.5 billion by the end of 2025? That’s a huge number! It’s growing fast because industries like electronics and healthcare need super-strong, heat-proof materials. So, if you’re wondering how to choose the right technical ceramic material, you’re in the right place. Technical ceramics are special materials that can handle tough jobs, like making phone parts or fixing teeth. Picking the right one can save time, money, and headaches. At Eshino Precision, we make it easy with our top-quality products like zirconia ceramics and alumina ceramics. Let’s dive into a simple guide to help you choose!

What Makes Technical Ceramics Special?

Unlike regular clay pots, technical ceramics are built for serious tasks. They’re tough, resist heat, and don’t wear out easily. Plus, the demand is soaring—electronics alone takes up 40% of the market, says a 2025 report from Market Research Future. That’s why picking the perfect material matters so much.

Why This Guide Helps You

This article breaks it all down: what they are, how to pick one, and why our ceramic parts rock. Whether you’re making car brakes or medical tools, we’ve got your back with easy steps and cool facts. Ready? Let’s go!

What Are Technical Ceramics? A Simple Explanation

Technical ceramics are like the superheroes of materials. They’re not like the pottery you make in art class. Instead, they’re strong, heat-proof stuff used in big industries. Think of them as special rocks that don’t break easily and can handle crazy jobs.

How They’re Different from Regular Ceramics

Regular ceramics, like cups or vases, break if you drop them. But technical ceramics? They’re tougher! For example, silicon nitride ceramics are so strong they’re used in engines. At Eshino Precision, we make these awesome materials for things like ceramic rods and ceramic seals. They’re built to last, not just look pretty.

Where You’ll Find Technical Ceramics

You see technical ceramics everywhere! In phones, they help with electronics because they don’t conduct electricity. In hospitals, zirconia fixes teeth. Even cars use silicon carbide for brakes. Pretty cool, right? Check out our blog on what are structural ceramics for more fun details.

Why They’re Awesome

These ceramics can take heat up to 2400°C (that’s super hot!) and stay strong. They also save money by lasting longer than metal or plastic. “Technical ceramics are game-changers because they combine strength and versatility like nothing else,” says Dr. Jane Lin, a ceramics expert from CeramTec Group. That’s why we love making them at Eshino Precision!

How to Pick the Perfect Technical Ceramic Material: Key Steps

Choosing the right technical ceramic material isn’t hard if you follow some simple steps. It’s like picking the best toy—you need to know what you want it to do. Here’s how to do it easily.

Step 1: Know What You Need

First, figure out what your project needs. Does it get super hot? Try high-temperature resistant ceramics. Need something tough? Zirconia rods are great. At Eshino Precision, we ask clients what their job is—like making medical tools—so we can help pick the best one.

Step 2: Check the Cool Features

Next, look at what each material can do. Some are hard, some block electricity, and others handle heat. For example, alumina is awesome for electronics because it’s an insulator. Compare them to find your match! Our Technical Ceramics 101 blog has more on this.

Step 3: Think About Cost and How It’s Made

Then, consider money and how it’s built. Silicon carbide might cost more but lasts forever in tough spots like oil and gas. We make sure our ceramic parts are affordable and available fast, shipping to over 30 countries.

Step 4: Make Sure It’s Top Quality

Finally, check if it’s good enough. Our ceramics meet ISO9001 standards, meaning they’re super reliable. We even passed Apple’s tough tests! Learn more about our quality in this blog. Follow these steps, and you’ll pick a winner every time.

Must-Know Properties of Technical Ceramic Materials

Technical ceramic materials have special powers—like superheroes! To choose the right one, you need to know these powers. Here are the big ones to look at.

Hardness: How Tough It Is

Hardness means it won’t scratch or break easily. Silicon carbide is the hardest, scoring 2800 HV (that’s a big number!). It’s perfect for cutting tools. Check our high-hardness page for more.

Heat Resistance: Handling Hot Stuff

Some ceramics can take crazy heat. Zirconia handles up to 2400°C, great for ovens or car parts. See how it works in our petrochemical blog.

Electrical Insulation: Blocking Sparks

This keeps electricity from flowing where it shouldn’t. Alumina is a champ at this, used in electronics. It’s got a strength of 17 kV/mm—super safe!

Heat Movement: Staying Cool

Thermal conductivity is how heat moves through it. Silicon carbide is awesome at this, up to 270 W/m·K, perfect for bearings. Our thermal conductivity page explains it all.

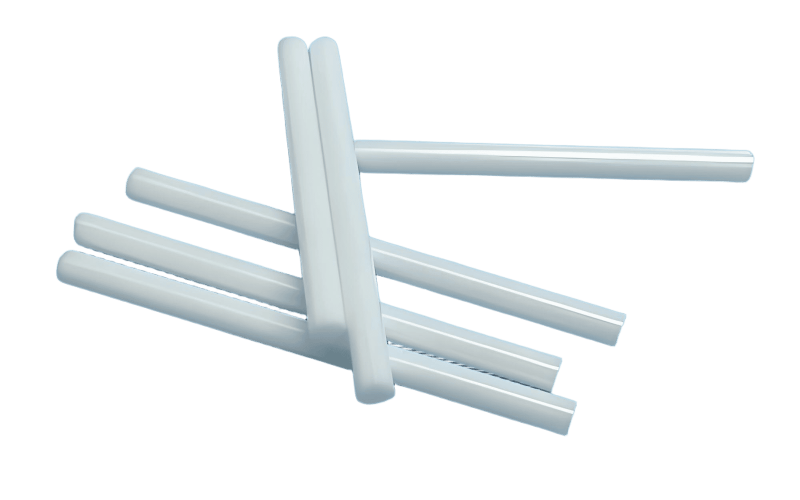

Zirconia Rod - Tough and Heat-Proof

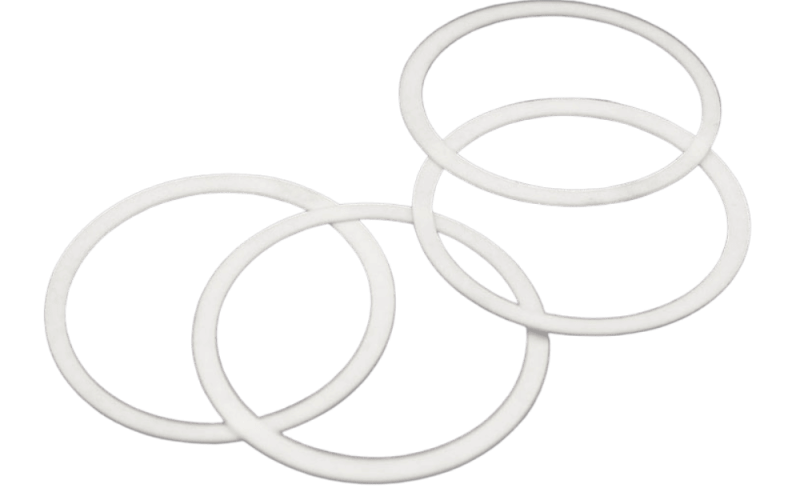

Alumina Seal - Blocks Electricity

Popular Technical Ceramic Materials and What They’re Used For

Technical ceramic materials come in different types, like picking your favorite superhero. Each one has special powers for different jobs. Let’s meet the big four and see what they do best!

Zirconia: The Tough Guy

Zirconia is super strong and doesn’t wear out fast. It’s perfect for dental implants and cutting tools. At Eshino Precision, we make zirconia rods that last a long time. Want more? Check our blog on zirconia benefits.

Alumina: The Electric Blocker

Alumina stops electricity, so it’s great for electronics like phone parts. It’s also tough and cheap for big projects. We offer alumina seals that keep things safe and working.

Silicon Nitride: The Hard Worker

Silicon nitride is crazy hard and strong. It’s used in car engines and bushings. Read more in our silicon nitride blog.

Silicon Carbide: The Heat Mover

Silicon carbide moves heat fast and doesn’t wear down. It’s awesome for bearings and chemical tools. We’ve got silicon carbide rods ready for you!

Matching Materials to Your Industry: Examples That Work

Different jobs need different technical ceramic materials. It’s like picking the right tool for a game. Here’s how they fit into big industries with examples that really work.

Electronics: Alumina Saves the Day

In electronics, things need to stay cool and safe from sparks. Alumina does this perfectly for circuit boards. Our ceramic substrates help make phones and computers better.

Medical: Zirconia Fixes Teeth

For medical stuff, materials must be safe and strong. Zirconia is used in dental implants because it’s tough and body-friendly. We make zirconia parts for doctors to trust.

Aerospace: Silicon Nitride Flies High

Aerospace needs light, heat-proof parts. Silicon nitride works in plane engines because it’s strong and light. Our silicon nitride rods are a hit here!

Automotive: Silicon Carbide Stops Cars

Cars need tough brakes. Silicon carbide handles heat and wear, so it’s great for automotive brakes. Check our ceramic discs for this job.

Cost, Supply, and Making It: Practical Things to Think About

Choosing a technical ceramic material isn’t just about powers. You also need to think about money, where to get it, and how it’s made. Let’s break it down.

Cost: How Much You’ll Pay

Some ceramics cost more than others. Zirconia is pricier because it’s hard to make, but alumina is cheaper for big batches. We keep prices fair at Eshino Precision. See how in this blog.

Supply: Can You Get It?

You need it when you need it! We ship to over 30 countries, so our ceramic parts are always ready. Whether it’s tubes or plates, we’ve got you covered fast.

Making It: How It’s Built

How we make it matters. For example, silicon carbide needs special heat to get super strong. Our manufacturing blog shows how we do it right for oil and gas tools.

Quality Matters: How to Ensure You’re Getting the Best

You want a technical ceramic material that won’t let you down. Quality is key! Here’s how to make sure it’s the best.

Standards: The Quality Rules

We follow ISO9001 rules at Eshino Precision. That means our ceramic parts are top-notch. They even passed Apple’s super-strict tests! It’s all about trust.

Testing: Checking It Works

We test stuff like how strong it is (called modulus of rupture) and how it handles heat. Our silicon nitride rods get checked to be perfect for semiconductors. Learn more in this page.

Why It’s Worth It

Good quality saves you money later. Our ceramic seals last long, cutting repair costs. Read how in this blog.

Real Stories: How Others Chose Their Technical Ceramic Materials

Real people picked the right technical ceramic materials and loved it. Here’s a story from our clients at Eshino Precision.

A Dentist’s Dream

One client needed zirconia for dental implants. They visited our factory, saw our cool machines, and said, “Wow, this is the best!” Now, they only use our zirconia rods because they’re strong and cheap. Check it out in this blog.

Why It Worked

They picked zirconia because it’s tough and safe for teeth. Our quick help sealed the deal. Real stories show how easy choosing can be!

What’s Next for Technical Ceramics in 2025 and Beyond

Technical ceramics are getting bigger in 2025! Here’s what’s coming and how it helps you pick the right one.

Big Growth Ahead

The market’s hitting $10.5 billion this year, says Market Research Future. Electronics uses 40%, and healthcare takes 25%. That’s huge!

New Uses

Tiny electronics and new medical tools need ceramics like alumina. We’re ready with substrates for the future.

Quick Reference: Compare Technical Ceramic Materials

Here’s a fast look at the big four technical ceramic materials to help you choose.

| Material | Hardness (HV) | Max Temp (°C) | Heat Move (W/m·K) | Cost |

|---|---|---|---|---|

| Zirconia | 1200 | 2400 | 2-3 | High |

| Alumina | 1500 | 1700 | 20-30 | Medium |

| Silicon Nitride | 1800 | 1900 | 15-20 | High |

| Silicon Carbide | 2800 | 1600 | 120-270 | Medium-High |

Your Questions Answered: Technical Ceramics FAQ

Got questions? Here are answers to what people ask about technical ceramic materials.

What Are the Most Common Technical Ceramics?

The big ones are zirconia, alumina, silicon nitride, and silicon carbide. We’ve got them all at Eshino Precision!

Which Ceramic Is Best for Hot Stuff?

Zirconia wins at 2400°C, but silicon carbide moves heat better. Pick based on your job!

Conclusion: Start Choosing with Confidence

Now you know how to choose the right technical ceramic material! First, figure out what you need. Then, check properties like hardness or heat resistance. Match it to your industry, think about cost, and ensure it’s high quality. At Eshino Precision, we’ve got ceramic parts like zirconia rods and alumina seals ready to help. Want to get started? Contact us today for expert help and top-notch ceramics!

External Links for More Info

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.