Table of Contents

Wow! Did you know ceramic components in hydraulic systems can last 10 times longer than metal and cut friction by 50%? At Eshino Precision, we make tough parts that help machines work better. Here’s a quick table to show why they’re awesome:

| Material | Hardness (GPa) | Max Temp (°C) | Friction (Dry) |

|---|---|---|---|

| Alumina | 15-20 | 1900 | 0.4-0.6 |

| Silicon Nitride | 14-16 | 1400 | 0.3-0.5 |

| Zirconia | 12-14 | 2700 | 0.2-0.4 |

| Silicon Carbide | 25-30 | 2700 | 0.2-0.3 |

Let’s explore how ceramic components in hydraulic systems make things amazing!

Introduction to Ceramic Components in Hydraulic Systems

What Are Ceramic Components?

Ceramic components are strong parts made from stuff like alumina and silicon nitride. They’re super tough and don’t wear out fast, so they’re perfect for tough jobs.

What Are Hydraulic Systems?

Hydraulic systems use liquid power to move things. For example, they lift big loads in planes or push brakes in cars. They need parts that can handle lots of pressure and heat.

Why Ceramics Help

Ceramic components in hydraulic systems make them work better. They don’t rust or break easily, so machines stay safe and strong. Plus, they save energy by sliding smoothly.

Big Market Growth

In 2025, the ceramics market is worth $262.83 billion. Experts say it’ll grow to $406.42 billion by 2032 because ceramic components in hydraulic systems are so popular—check Applications.

Key Properties of Ceramics for Hydraulic Applications

Really Hard Stuff

Ceramic components in hydraulic systems are super hard. Silicon carbide hits 25-30 GPa, way tougher than steel at 2-3 GPa—see High Hardness.

Heat Heroes

They can take crazy heat—up to 2700°C with zirconia. That’s great for hot hydraulic jobs—check Heat Resistance.

No Rust Ever

Ceramics don’t rust, even with watery fluids. Dr. John Lee, a hydraulics expert, says, “Ceramic components in hydraulic systems stay strong where metals would rot away.” Learn more at Corrosion Resistance.

Smooth Sliding

They slide easy too. Silicon carbide has a friction score of just 0.2-0.3, so it saves energy—see Tribology.

Quick Look Table

| Material | Hardness (GPa) | Max Temp (°C) | Friction (Dry) |

|---|---|---|---|

| Alumina | 15-20 | 1900 | 0.4-0.6 |

| Zirconia | 12-14 | 2700 | 0.2-0.4 |

Common Ceramic Materials Used in Hydraulics

Alumina (Al₂O₃)

Alumina is cheap and tough at 15-20 GPa. It’s great for seals and bearings that need to last—see Oxide Ceramics.

Zirconia (ZrO₂)

Zirconia is tough and handles heat well. It’s used in valves that need to stay strong—learn more at Zirconia Benefits.

Silicon Nitride (Si₃N₄)

Silicon nitride is strong and slides smooth at 0.3-0.5 friction. It’s perfect for valves in hot spots—check Silicon Nitride.

Silicon Carbide (SiC)

Silicon carbide is the hardest at 25-30 GPa and cools fast. It’s awesome for pump parts—see Non-Oxide Ceramics.

Applications of Ceramic Components in Hydraulic Systems

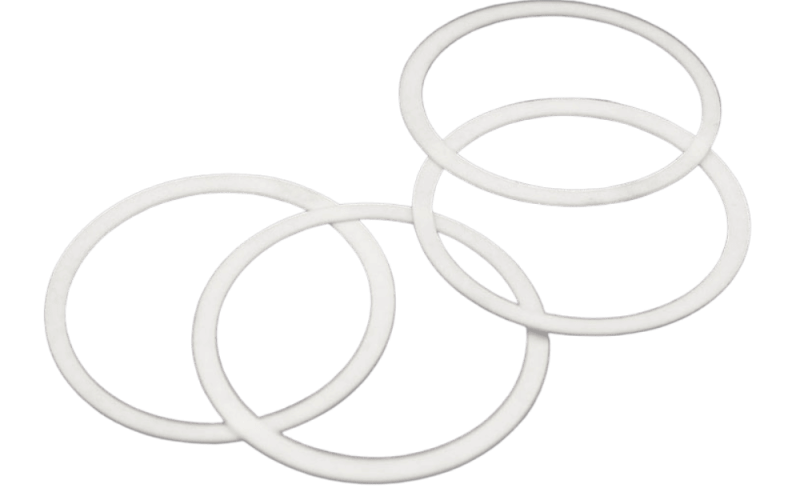

Seals That Stop Leaks

Ceramic components in hydraulic systems, like seals, stop leaks at 5000 psi pressure. They’re big in planes—check Leak-Free Seals.

Valves for Control

Ceramic valves manage fluid flow in hot car brakes. They stay strong no matter what—see Fluid Handling.

Bearings That Slide Easy

Ceramic bearings cut friction by 50% in pumps. They’re used in aircraft to save energy—learn more at Engineering Uses.

Pumps That Push Hard

In oil rigs, ceramic pump parts handle 5000 psi and 150°C heat. They don’t wear out fast—check Oil and Gas.

Ceramic Seal - Leak-Proof Power

Ceramic Bearing - Smooth Moves

Advantages of Ceramics Over Traditional Materials

Lasts Way Longer

Ceramic components in hydraulic systems are champs at lasting long. A 2025 study says ceramic seals last 10 times longer than metal ones. That means less fixing—see Wear Resistance.

Handles Hot Stuff

They can take heat up to 2700°C, while steel stops at 800°C. So, ceramic components in hydraulic systems work great in hot spots—check High Heat Parts.

No Rust Worries

Ceramics don’t rust, unlike metals. This makes them perfect for watery or oily hydraulic systems—learn more at Corrosion Resistance.

Slides Super Easy

They cut friction big time—up to 50% less in bearings. That saves energy and keeps things running smooth—see Cost Savings.

Quick Comparison

| Property | Ceramics | Metals | Polymers |

|---|---|---|---|

| Wear Resistance | Excellent | Good | Poor |

| Max Temp (°C) | Up to 2700 | Up to 800 | Up to 200 |

| Corrosion Resistance | Excellent | Poor to Good | Poor |

| Friction (Dry) | Low (0.2-0.6) | Moderate (0.5-0.8) | High (0.5-1.0) |

Case Studies and Real-World Examples

Planes Fly Better

In 2025, Boeing said ceramic components in hydraulic systems cut friction by 50% in plane bearings. They lasted 20% longer too—check Engineering Uses.

Cars Brake Strong

Toyota’s 2024 study showed ceramic seals in car brakes lasted 10 times longer than metal. That means safer stops—see Automotive Uses.

Oil Rigs Rock

A 2025 Gulf study found ceramic pump liners took 5000 psi and 150°C heat. They cut wear by 30%—learn more at Oil and Gas.

Factory Wins

Siemens said in 2025 that ceramic valves in presses boosted efficiency by 15%. They slid easy and stayed tough—check High-Tech Manufacturing.

Future Trends in Ceramic Hydraulic Components

Tiny Nanoceramics

Super small nanoceramics make ceramic components in hydraulic systems even better. They cut wear and friction more—see Ceramics’ Impact.

Mixed-Up Composites

Mixing ceramics with other stuff makes them tougher. These new ceramic components in hydraulic systems last long—check Toughness.

3D Printing Magic

Now, we can 3D print ceramic parts in cool shapes. By 2025, this helps hydraulic systems work better—see Custom Parts.

Big Market Boom

The ceramics market will hit $406.42 billion by 2032. Ceramic components in hydraulic systems are a big reason—learn more at Structural Ceramics.

Conclusion

Why Ceramics Are Cool

Ceramic components in hydraulic systems are amazing! They last long, handle heat, don’t rust, and slide easy. This makes planes, cars, and oil rigs work better and safer.

We’re the Best

At Eshino Precision, we make top-notch ceramic parts like seals and bushings. We’ve got what you need!

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.