Table of Contents

Wow, did you know? Ceramic seals can last up to 5 years while metal seals wear out in just 1.5 years. Plus, they can save you 40% on fixing costs! That’s huge for machines like pumps and engines. Check out this quick table to see why ceramic seals for mechanical applications are so cool:

| Seal Type | How Long It Lasts | Cost Over 5 Years |

|---|---|---|

| Metal | 1.5 years | $6,667 |

| Ceramic | 5 years | $3,000 |

So, what are ceramic seals for mechanical applications? They’re tough little parts that stop leaks in machines. Made from stuff like alumina or silicon carbide, they keep things tight in tough jobs like oil drilling or car engines. At Eshino Precision, we make these seals to help you. Let’s dig in and see why they’re awesome!

What Are Ceramic Seals and Why They Matter

What’s a Ceramic Seal?

Think of ceramic seals as super-strong guards for machines. They’re made from special materials like alumina, silicon carbide, or zirconia. These aren’t like your grandma’s clay pots—they’re built to be hard and tough. In mechanical applications, they stop fluids or gases from leaking out of things like pumps or engines.

Why are they special? Because machines face big challenges—like super-hot temperatures or scratchy stuff that wears things out. Regular seals made of metal or rubber break down fast. But ceramic seals for mechanical applications keep going strong. We make them at Eshino Precision to be extra tough.

Why They’re a Big Deal

Machines need to work without leaking, right? That’s where ceramic seals shine. They handle heat better than metal—think over 200°C! They don’t rust in yucky liquids, and they don’t wear out easily. “Ceramic seals are a game-changer for keeping systems leak-free,” says Dr. Mark Evans from CoorsTek. This means less fixing and more working, which saves you time and money.

For example, our silicon carbide seals are perfect for tough spots. Want to know more about why ceramics are cool? Check out our blog on ceramic properties.

Key Applications of Ceramic Seals

Where You’ll Find Them

Ceramic seals for mechanical applications pop up in lots of places. They’re like the heroes keeping machines leak-free. Here’s where they work hard:

- Pumps and Compressors: In oil and gas or water plants, these seals stop leaks in pumps moving rough liquids.

- Rotating Equipment: Think turbines or fast-spinning machines in planes—they stay tight with ceramic seals.

- Valves: In super-hot or high-pressure valves, like in power plants, they keep things sealed up.

- Cars and Planes: Engines and brakes use them to handle heat and wear.

They’re awesome because they last so long. Look at our ceramic valves for more examples!

A Real-Life Win

Here’s a cool story: An oil company used our ceramic seals in their pumps. Guess what? Seal failures dropped by 80%! That means they didn’t have to stop and fix stuff as much, saving big bucks. It’s all about keeping things leak-free in mechanical applications. Want to see how they help oil rigs? Read this blog.

Types of Ceramic Seals and Their Uses

Different Kinds of Seals

Not all ceramic seals are the same—they come in different shapes for different jobs. Here’s a quick rundown:

- Mechanical Seals: These stop leaks in pumps or spinning machines. They’re two flat pieces that slide together.

- Lip Seals: Used in car engines where a shaft spins—they keep oil in.

- Labyrinth Seals: Fancy non-touch seals with twisty paths—great for turbines.

- Gasket Seals: Flat seals for hot or yucky joints, like in chemical plants.

We’ve got tons of options at Eshino Precision—check them out!

Which One Fits Where?

Choosing the right seal is easy when you know what’s up. Here’s a simple table to help:

| Type | Best For | Where It’s Used |

|---|---|---|

| Mechanical | Pumps, spinning stuff | Oil pumps |

| Lip | Shafts | Car engines |

| Labyrinth | Fast machines | Turbines |

| Gasket | Hot joints | Chemical valves |

Need a custom fit? Our custom ceramic parts can match any job!

How Ceramic Seals Ensure Leak-Free Operation

What Makes Them Leak-Proof

Ceramic seals for mechanical applications are champs at stopping leaks. How? They’ve got some neat tricks:

- Smooth Faces: They’re polished super smooth, so no gaps let stuff sneak out.

- Super Hard: They don’t wear down, keeping the seal tight for years.

- Heat-Friendly: They don’t stretch or shrink much in heat, staying snug.

- No Rust: Chemicals can’t hurt them, so they stay strong.

In pumps, for instance, two ceramic pieces press together and don’t let anything through. It’s like a perfect hug!

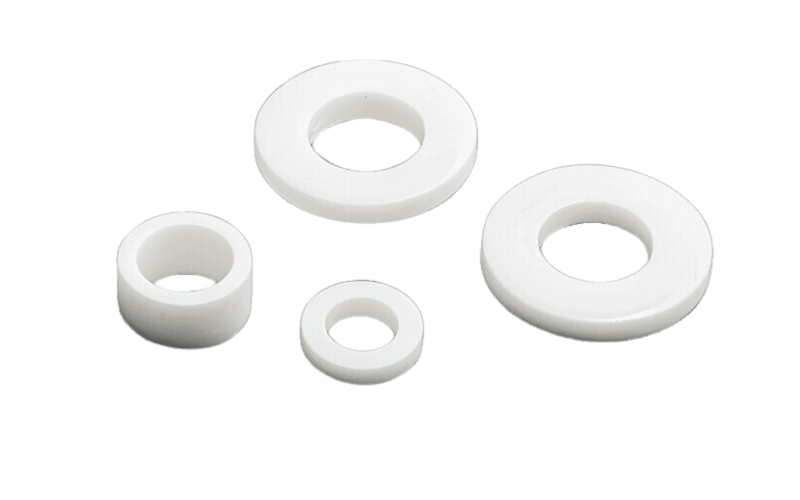

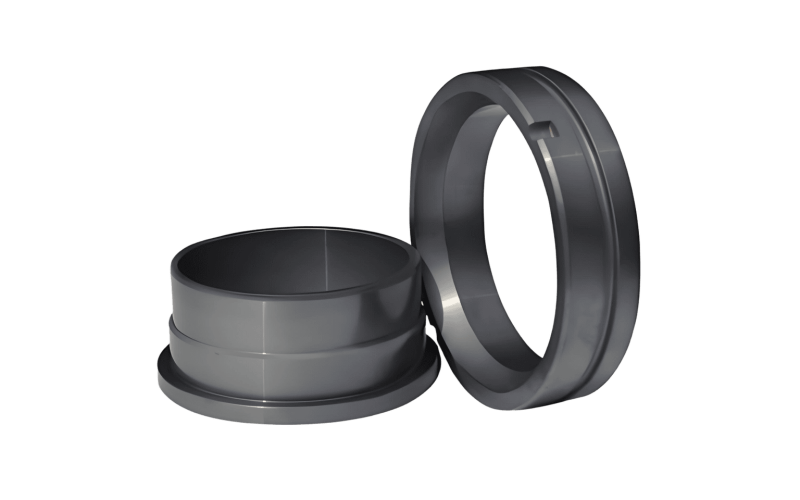

Pictures of the Magic

Check out these side-by-side pics of our seals:

These seals keep things leak-free in mechanical applications. Learn more about their toughness at high hardness.

Performance and Economic Benefits

How They Perform Better

Ceramic seals for mechanical applications are like superheroes compared to metal seals. They last way longer—up to 5 years instead of just 1.5 for metal. Plus, they don’t wear out fast because they’re so hard. This means your machines, like pumps or engines, keep running without leaks. And they handle hot stuff and yucky chemicals better than metal ever could.

Here’s a quick list of why they rock:

- Long Life: Fewer swaps mean less stopping.

- Leak-Free: They keep everything inside where it belongs.

- Safe: No leaks mean fewer messes or dangers.

Our zirconia seals are a great example—they’re tough and reliable!

Saving Money and the Planet

Now, let’s talk cash. Ceramic seals for mechanical applications cost more at first—like $3,000 each vs. $2,000 for metal. But over 5 years, metal seals add up to $6,667 because you replace them more. Ceramic seals? Just $3,000 total. Check this out:

| Seal Type | Life | Cost per Seal | 5-Year Cost |

|---|---|---|---|

| Metal | 1.5 years | $2,000 | $6,667 |

| Ceramic | 5 years | $3,000 | $3,000 |

Plus, they help the Earth! Fewer replacements mean less trash. “Ceramic seals cut costs and waste,” says Lisa Patel, a green tech expert. Want more on savings? See this blog.

Challenges and Practical Solutions

Tricky Stuff About Ceramic Seals

Ceramic seals for mechanical applications aren’t perfect—they’ve got some downsides. First, they can break if you drop them hard because they’re brittle. Second, they cost more to start with. And third, making them fit just right is tough since they’re super hard to shape.

But don’t worry—we’ve got ways to fix these problems at Eshino Precision!

Easy Fixes That Work

Here’s how we handle those challenges:

- Brittleness: We use tougher stuff like zirconia so they don’t crack as easy.

- Cost: They save money later, and new tricks like 3D printing make them cheaper to make.

- Shaping: Fancy tools like lasers get them perfect every time.

So, ceramic seals stay awesome even with these issues. Curious about toughness? Check out this page.

Tips for Choosing the Right Ceramic Seal

How to Pick the Best One

Want the perfect ceramic seal for mechanical applications? Here’s what to think about:

- What It Touches: Pick alumina for clean stuff or silicon carbide for rough stuff.

- Heat: Zirconia’s great if it gets really hot—like in pumps.

- Pressure: Big pressure needs strong seals, like for valves.

- Speed: Fast spinning? Make sure it’s smooth and tough.

Size matters too—it’s gotta fit just right. We can help with that!

Get Help From Experts

Not sure which one? Talk to us at Eshino Precision. We’ll match your job to the best seal. “Choosing the right seal keeps things leak-free,” says John Carter, a pump engineer. Visit our solutions page to see your options. Let’s make your machines unstoppable!

Frequently Asked Questions

Stuff People Want to Know

Lots of folks ask about ceramic seals for mechanical applications. Here are some big questions:

- What kinds are there? Mechanical, lip, labyrinth, and gasket seals.

- How do they beat metal? They last longer and don’t rust.

- Who uses them? Oil, gas, car makers, and plane builders.

Got more? Our ceramics 101 blog has answers!

More Quick Answers

Here’s extra info:

- New tricks? Better mixes and 3D printing make them even cooler.

- When to use them? For hot, rough, or fast jobs where leaks are bad news.

Check out where they shine at mechanical engineering applications.

Conclusion: The Future of Ceramic Seals

Why They’re Here to Stay

Ceramic seals for mechanical applications are the future! They’re tough, save money, and keep leaks away. With a market growing 7.4% every year from 2024 to 2029, more people are catching on. They last longer, cut fixes by 40%, and even help the planet with less waste. From oil pumps to car engines, they’re making machines better.

Ready to Transform Your Engineering Solutions?

Ready to stop leaks for good? At Eshino Precision, we’ve got the best ceramic seals—like alumina or silicon nitride. Contact us by following contact button to find the perfect fit. Let’s keep your machines running smooth and leak-free!