Key Takeaway Table: Why Silicon Carbide Ceramic Bushings Are the Best!

Here’s a fast look at why silicon carbide ceramic bushings rule! This table spills the top info you need right away.

| Cool Feature | Why It’s Awesome for You |

| Ultra-Hard | Fights off wear from sand and rocks |

| Heat Champ | Stays strong up to 1650°C |

| Corrosion Buster | Won’t break down in nasty chemicals |

| Heat Conductor | Keeps your machine from overheating |

| Tough and Reliable | Lasts long in the roughest conditions |

Want more details? Let’s dig into what makes silicon carbide ceramic bushings so amazing!

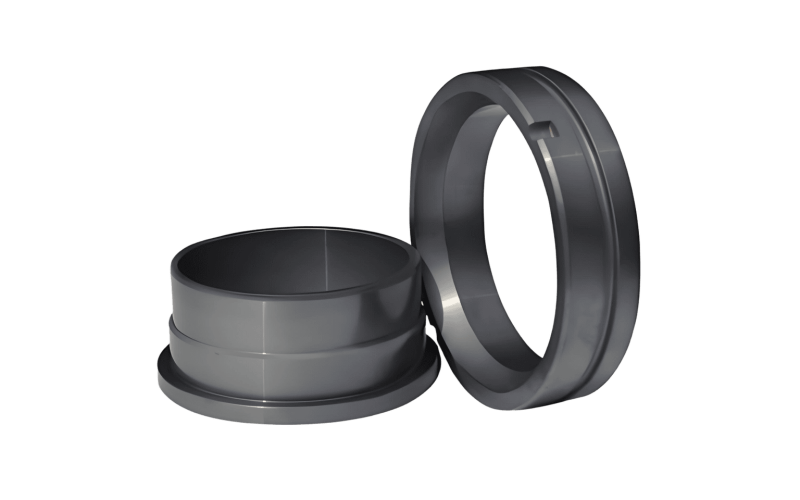

A silicon carbide ceramic bushing is a sleeve made from silicon carbide (SiC), a super tough ceramic material. It slips between moving parts in machines to cut friction and stop wear. Picture it as a rock-solid guard that keeps things sliding smoothly, even in the toughest spots.

Silicon carbide is famous for being one of the hardest materials around. It’s perfect for jobs where other stuff—like metal or plastic—wears out fast. So, if you need a bushing that can take a beating and keep going, this is it!

Silicon carbide ceramic bushings have some killer features. Here’s why they’re a total win:

Silicon carbide is crazy hard, with a Mohs hardness of 9.5. That’s almost as tough as diamond! It laughs off scratches from sand, grit, or rocks. For example, in a pump with dirty water, it stays strong while others wear out.

These bushings can take heat up to 1650°C without melting or bending. That’s hotter than lava! So, if your machine gets blazing hot—like in a furnace or engine—it keeps working like a champ.

Silicon carbide doesn’t let acids, bases, or salty water mess with it. It’s perfect for tough places like chemical plants or oil rigs. No rust, no breakdown—just pure toughness!

Unlike some ceramics, silicon carbide moves heat away fast, with high thermal conductivity. This keeps your machine cooler and running better. For instance, in a seal, it stops overheating and saves the day.

These bushings are built to last in the wildest conditions. They handle pressure, heat, and wear without quitting. So, in a heavy-duty job, they keep your equipment going strong for ages.

These perks make silicon carbide ceramic bushings a go-to for serious work!

Not sure where to use these bushings? They’re perfect for tons of jobs! Check out these spots:

Wherever you need strength and stamina, silicon carbide ceramic bushings deliver!

Let’s stack silicon carbide up against metal and plastic bushings. This shows why it’s often the top pick!

Metal bushings are solid, but they’ve got limits:

Silicon carbide wins with better wear resistance, no rust, and killer heat handling. It’s a step above for rough jobs!

Plastic is light and cheap, but it’s not always great:

Silicon carbide brings more strength, heat power, and staying power. It’s perfect for hard-core tasks!

This proves silicon carbide ceramic bushings often beat the competition.

Need the details? Here’s a table with the key specs for silicon carbide ceramic bushings. It’s simple and clear!

| Property | Value |

| Material | Silicon Carbide (SiC), high-purity ceramic |

| Hardness | Mohs 9.5 (nearly diamond-level!) |

| Density | 3.15 g/cm³ (light but tough) |

| Max Temperature | Up to 1650°C (insanely hot!) |

| Sizes | Customizable—any size you want |

| Surface Finish | Smooth for less friction |

| Tolerance | As tight as ±0.001mm (super precise!) |

These specs help you pick the perfect bushing. For example, if you need exact sizes for a tight fit, we’ve got it!

To keep your silicon carbide ceramic bushing in top shape, here’s what to do. It’s simple stuff!

Installation Tips

Maintenance Hacks

These tips make sure your bushing lasts long and works great!

Ready to power up your machines with something ultra-tough and reliable? Silicon carbide ceramic bushings are the way to go!

We will get back to you within 12 hours.

We will be in touch within 12 hours. Your intellectual property is 100% secure with us.